Exhaust gas purifying catalyst and manufacturing method thereof

A technology of exhaust gas purification and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of poor durability and reduced activity of precious metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

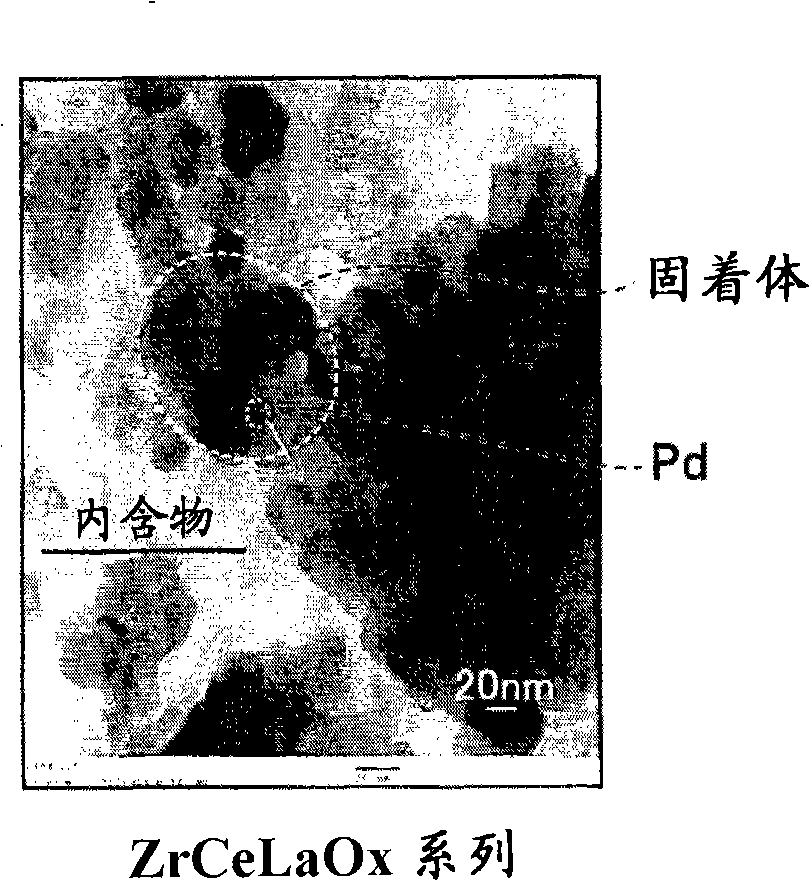

Image

Examples

Embodiment 1

[0065]

[0066] The acetic acid Rb was impregnated into and supported on the cerium oxide nanoparticle powder so that the concentration of the acetic acid Rb was 5 mol % with respect to the cerium oxide, followed by drying. In addition, the above product was calcined at 600° C. for 3 hours in an air atmosphere to obtain the first compound of Example 1.

[0067] The formed first compound powder was measured by XRD and calculated using the Scherrer formula to obtain the crystallite diameter, as shown in Table 1.

[0068] The tetraamine Pd solution was supported on the powder obtained in the above steps so that the noble metal support concentration was 0.5 wt% relative to the powder, dried, and then calcined at 400° C. in air.

[0069] Grinding the resulting Pd(0.5 wt%) / CeRbO in aqueous solution x powder to obtain a dispersion slurry with an average particle diameter of 310 nm.

[0070] Meanwhile, the dispersion slurry of the noble metal-loaded first compound obtained in the ...

Embodiment 2

[0075] The catalyst honeycomb body of Example 2 was obtained in the same manner as in Example 1, except that the acetic acid Rb in the above powder preparation step was changed to acetic acid Ba.

Embodiment 3

[0077]The catalyst honeycomb body of Example 3 was obtained in the same manner as in Example 1, except that the acetic acid Rb in the above powder preparation step was changed to acetic acid Cs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com