Method for processing prestress square pile

A processing method and prestressing technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of time-consuming, labor-intensive, erosion, and durability-affected reinforcement cages, and achieve improved crack resistance and ultimate bending moment, Improve the tensile bearing capacity of the structure and the effect of increasing the vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

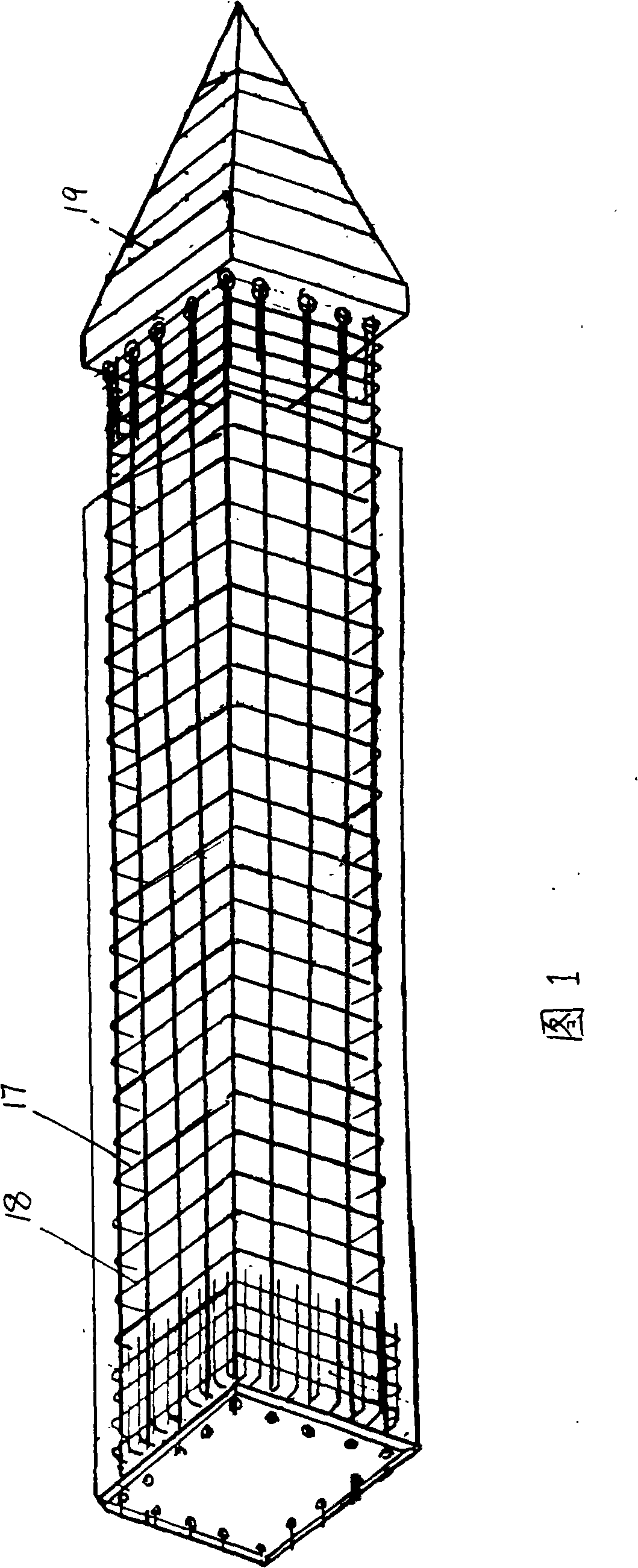

[0019] Process and produce prestressed concrete solid piles as shown in Figures 1 and 2 as follows:

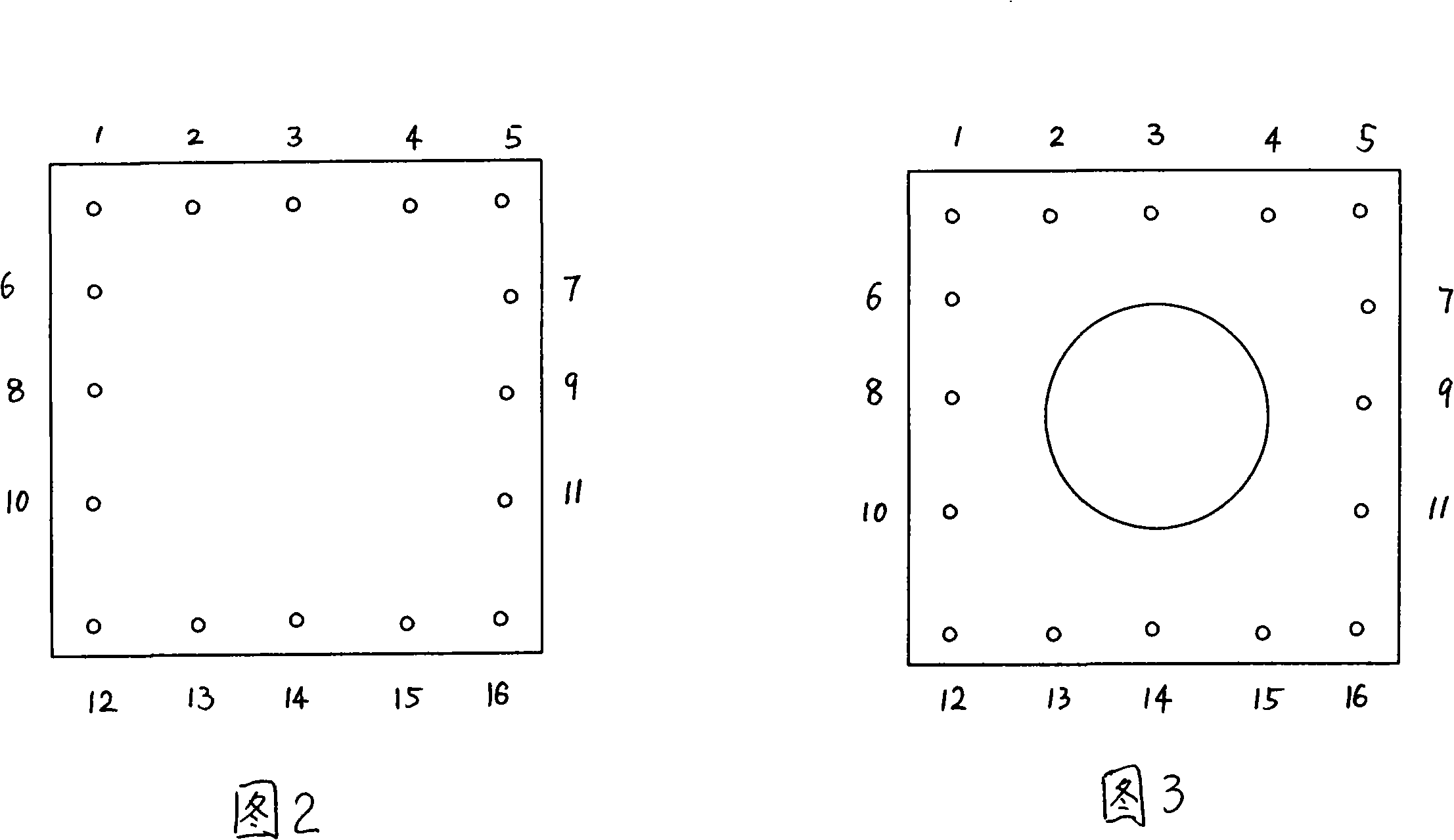

[0020] The first step of threading the reinforcement: first place the square and octagonal spiral stirrups and prefabricated pile tips on the prestressed tensioning platform, and then thread the octagonal main reinforcement inside the inner octagonal spiral stirrup according to the hole position of the end formwork, that is, 2, 4 , No. 15, 13, 7, 11, 10, and No. 6 holes wear the main rib to form the inner octagonal main rib, and then wear the four-corner main rib at the four corners of the four-corner stirrup, that is, the No. 1, 5, 16, and No. 12 holes wear the main rib to form an outer The quadrilateral main rib is locked with a tracing tool at both ends;

[0021] The second step of tensioning: the tensioning control stress is 70% of the standard strength of the steel bar. Firstly stretch the inner octagonal main reinforcement on the opposite side of the main reinforcement ...

Embodiment 2

[0025] Process and produce prestressed concrete hollow piles as shown in Figures 1 and 3 as follows:

[0026] The first step is to thread the reinforcement: first place the square spiral stirrup 17, the octagonal spiral stirrup 18 and the prefabricated pile tip 19 on the prestressed tensioning table, and then thread the octagonal spiral stirrup in the inner octagonal spiral stirrup according to the hole position of the end template. The main reinforcement of the spiral rib steel bar, that is, No. 2, 3, 4, 15, 14, 13, 7, 11, 10, and No. 6 holes wear the main reinforcement to form an inner octagonal main reinforcement, and then wear the four-corner main reinforcement at the four corners of the four-corner stirrup, that is, 1 , No. 5, 16, and 12 holes pass through the main rib to form an outer quadrilateral main rib, and lock both ends with a tracing tool;

[0027] The second step of tensioning: the tensioning control stress is 70% of the standard strength. Firstly stretch the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com