Quasi-stable state method solid body thermal conductivity measurement instrument

A technology of thermal conductivity and measuring instruments, which is applied in the experimental measurement of solid thermal conductivity and the field of solid thermal physical property testing, and can solve the problems of uneven heating of the heating plate, time-consuming and laborious, and narrow measurement range of solid thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

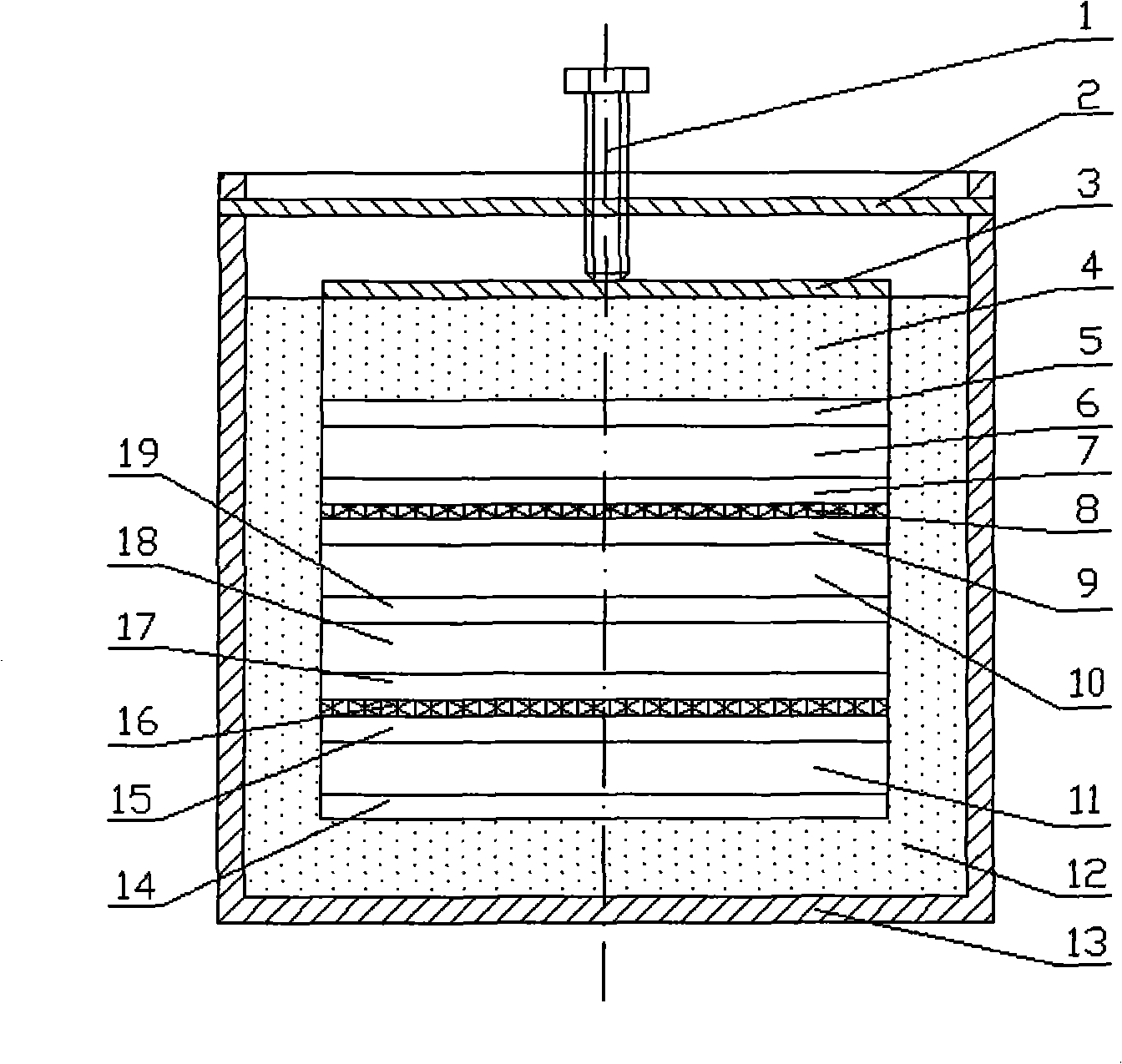

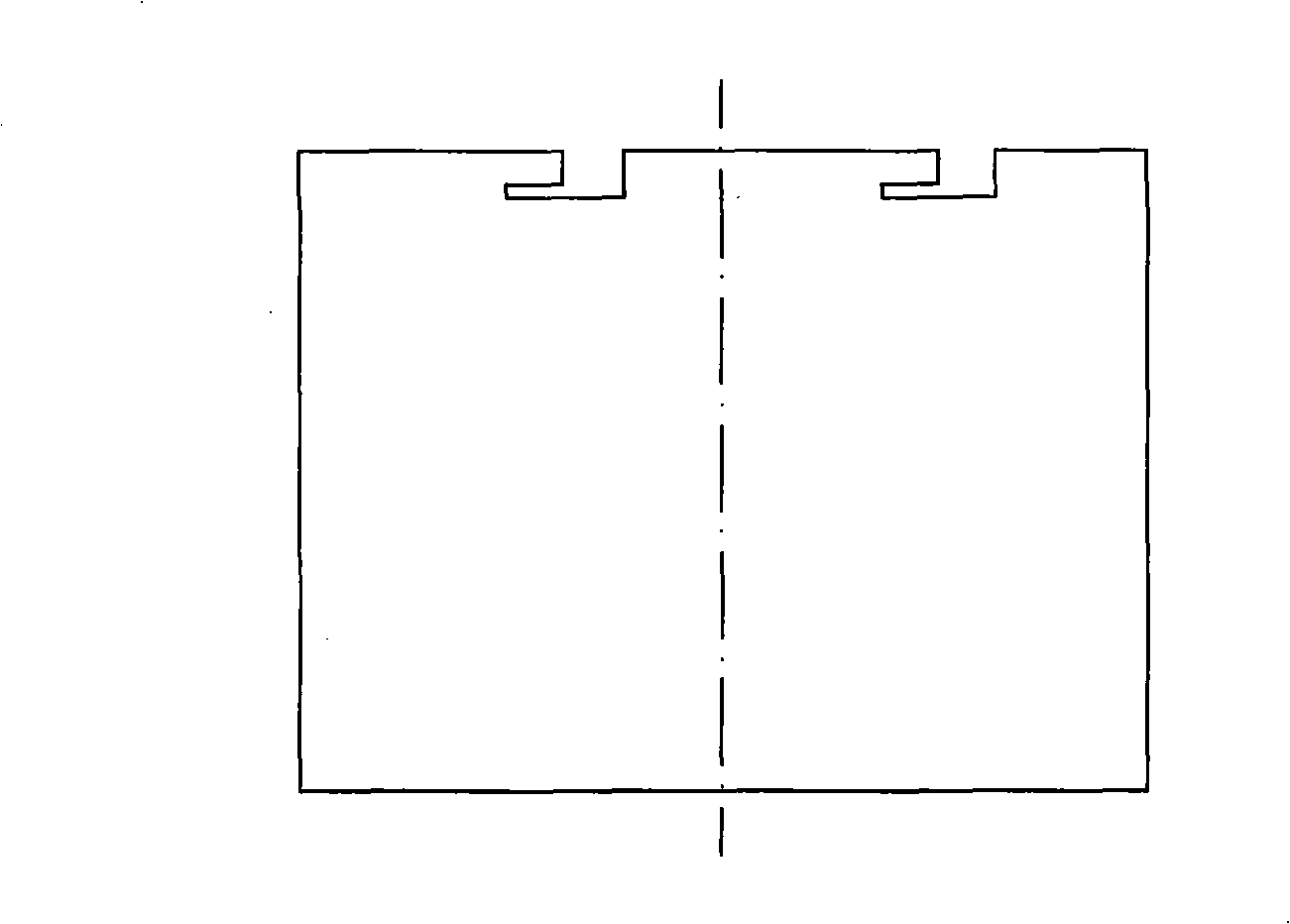

[0022] refer to figure 1 , quasi-steady-state thermal conductivity measuring instrument, comprising: a measuring container 13, the upper end of the measuring container 13 is provided with a stainless steel cover 2, the middle of the cover 2 is threaded, and a bolt 1 is installed. The measuring container 13 is filled with thermal insulation material 12, and the center of the thermal insulation material 12 forms a cavity, the upper part of the cavity is provided with a thermal insulation cover 4, and the upper part of the thermal insulation cover 4 is provided with a pressing metal sheet 3, the thickness of which can be 2 to 5 mm. Aluminum sheet or stainless steel sheet. The bolt 1 squeezes and compresses the metal sheet 3, and the extrusion force can be adjusted by adjusting the bolt 1 up and down.

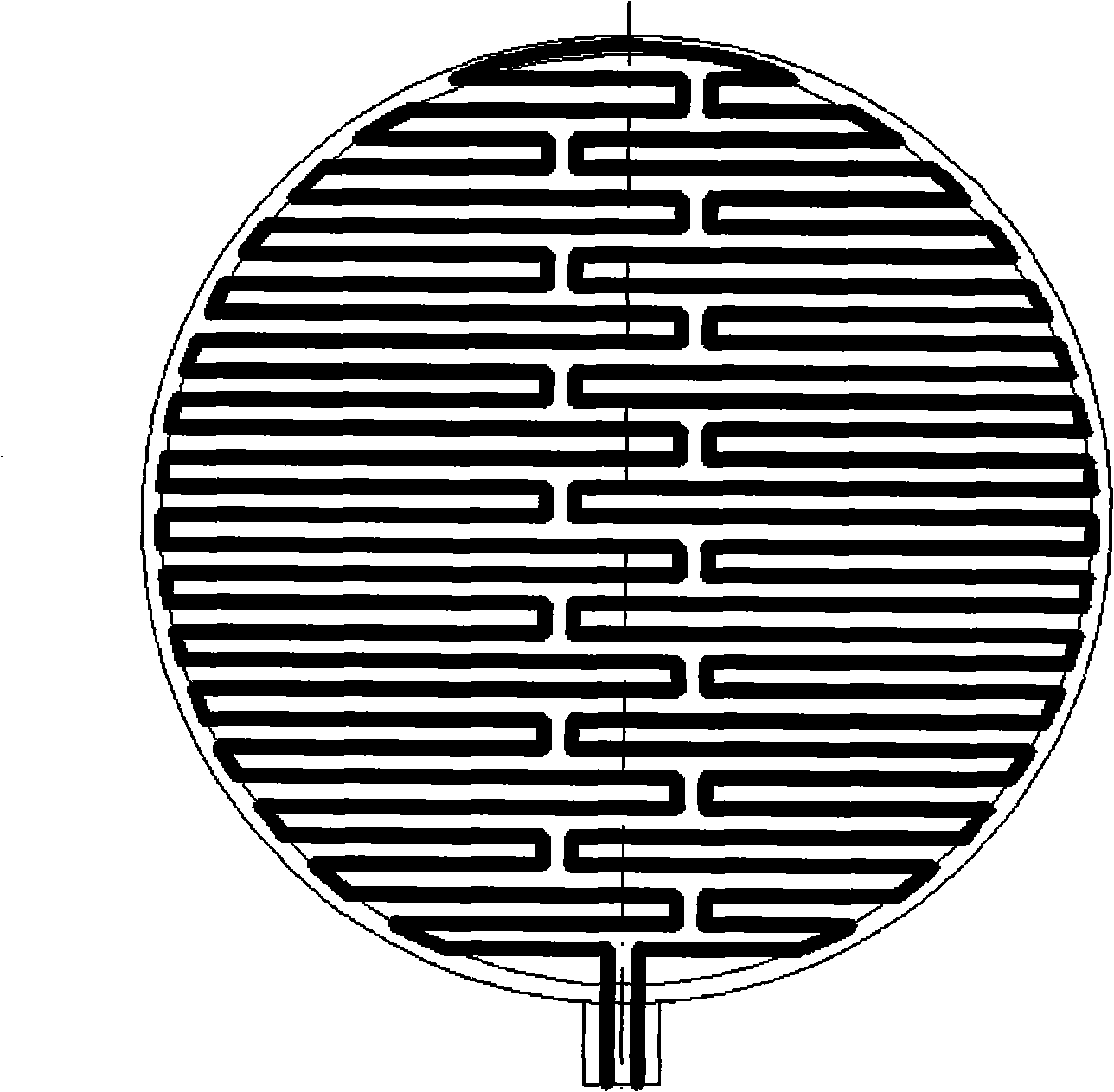

[0023] In the middle of the cavity of the thermal insulation material 12, the first soaking metal sheet 5 with the first thermocouple, the first sample 6, the second soaking metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com