System for transmitting control signal of high voltage frequency converter power unit

A high-voltage frequency converter and power unit technology, applied in signal transmission systems, non-electrical signal transmission systems, output power conversion devices, etc., can solve the problem of inability to overcome transmission delay and transmission speed, the highest voltage can only reach 4160 volts, Problems such as application limitations, to achieve the effect of low cost, improved reliability, and good technical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

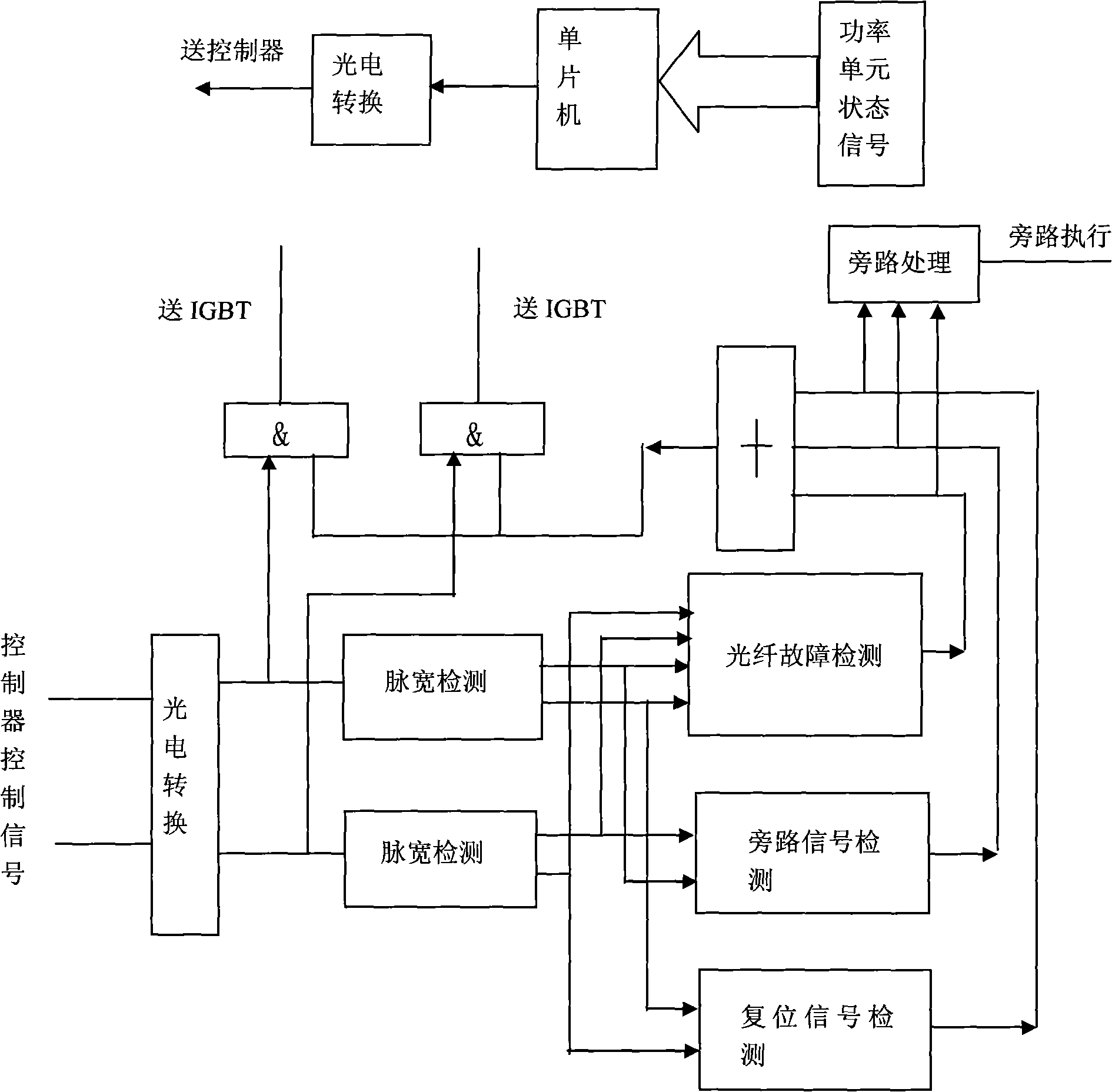

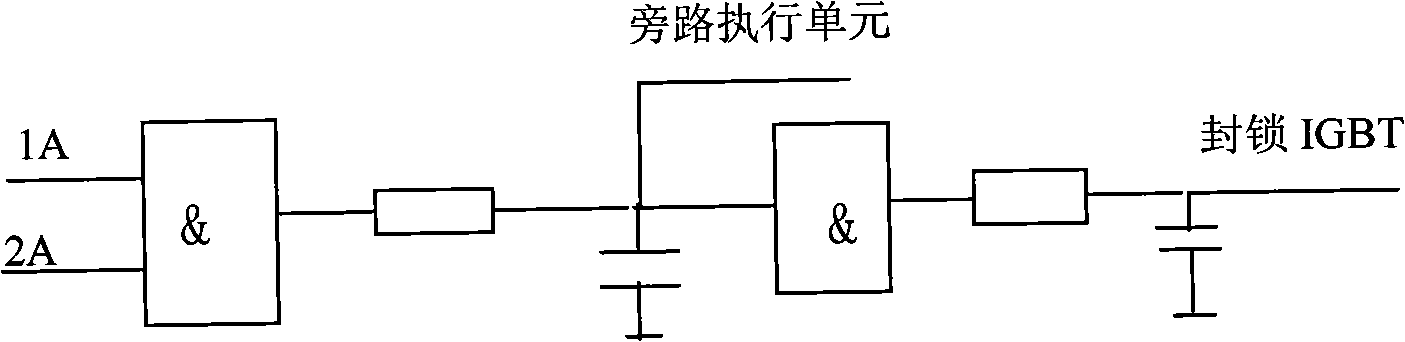

[0021] like figure 1 As shown, the transmission system of the embodiment of the present invention includes three optical fibers connected between the power unit and the controller for signal transmission; one of the optical fibers is used to transmit the uplink signal sent by the power unit to the controller, and the status signal of the power unit After the single-chip microcomputer and the electrical / optical conversion circuit, the optical fiber is used to transmit to the controller; the other two optical fibers are used to transmit the downlink signal sent by the controller to the power unit, the power unit IGBT drive signal and the power unit control signal sent by the controller After being transmitted by two optical fibers, it is sent to the power unit after passing through the optical / electrical conversion circuit.

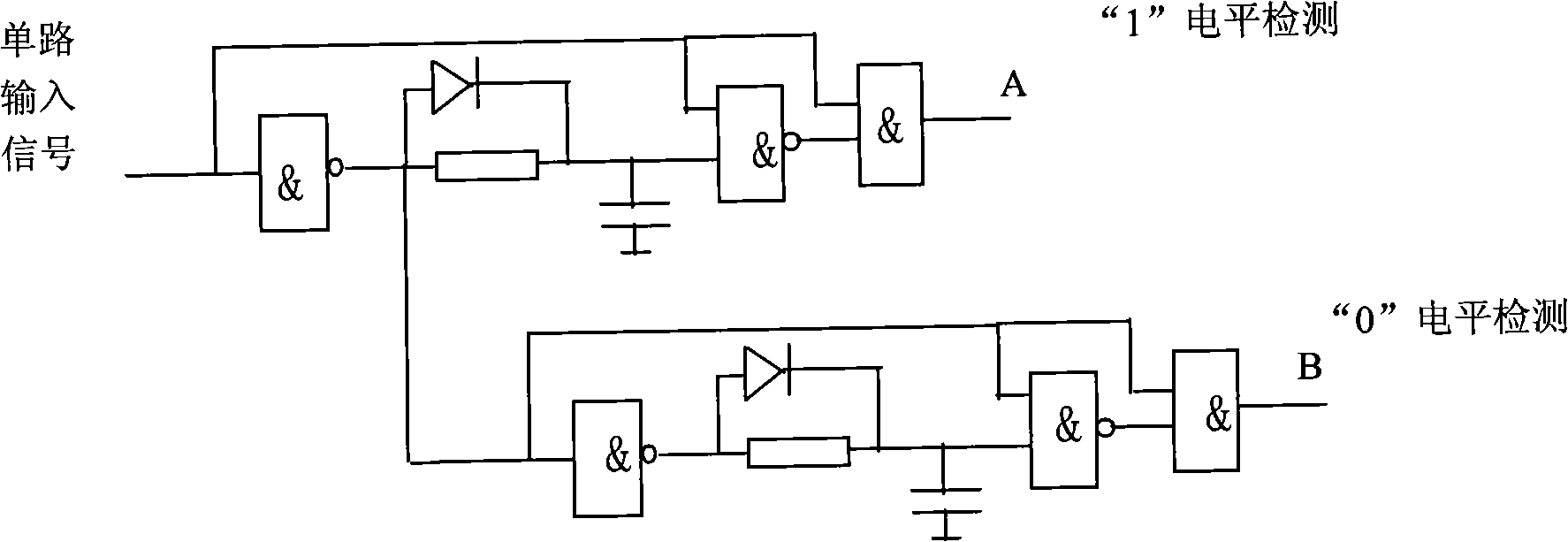

[0022] Among the above-mentioned downlink signals, the power unit IGBT driving signal is a real-time control signal of PWM waveform calculated and determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com