X ray collimator apparatus

A collimator and X-ray technology, applied in the direction of using apertures/collimators, measuring devices, instruments, etc., can solve the problems of assembly adjustment and replacement difficulties, X-ray entry, penumbra generation, etc., to avoid leakage. The interference of radiation and stray scattered rays, the convenience of processing and assembly and debugging, and the effect of improving the accuracy of test and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

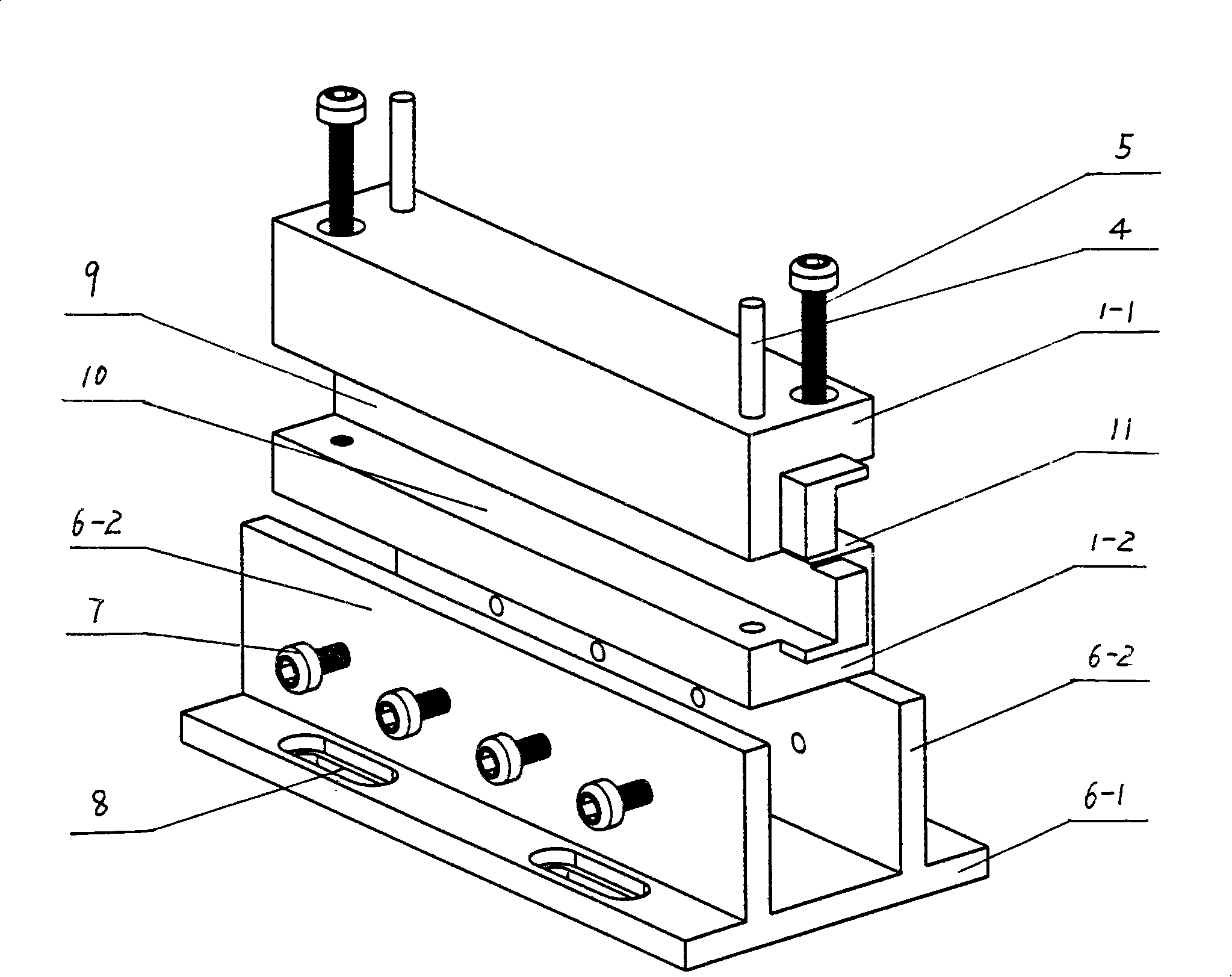

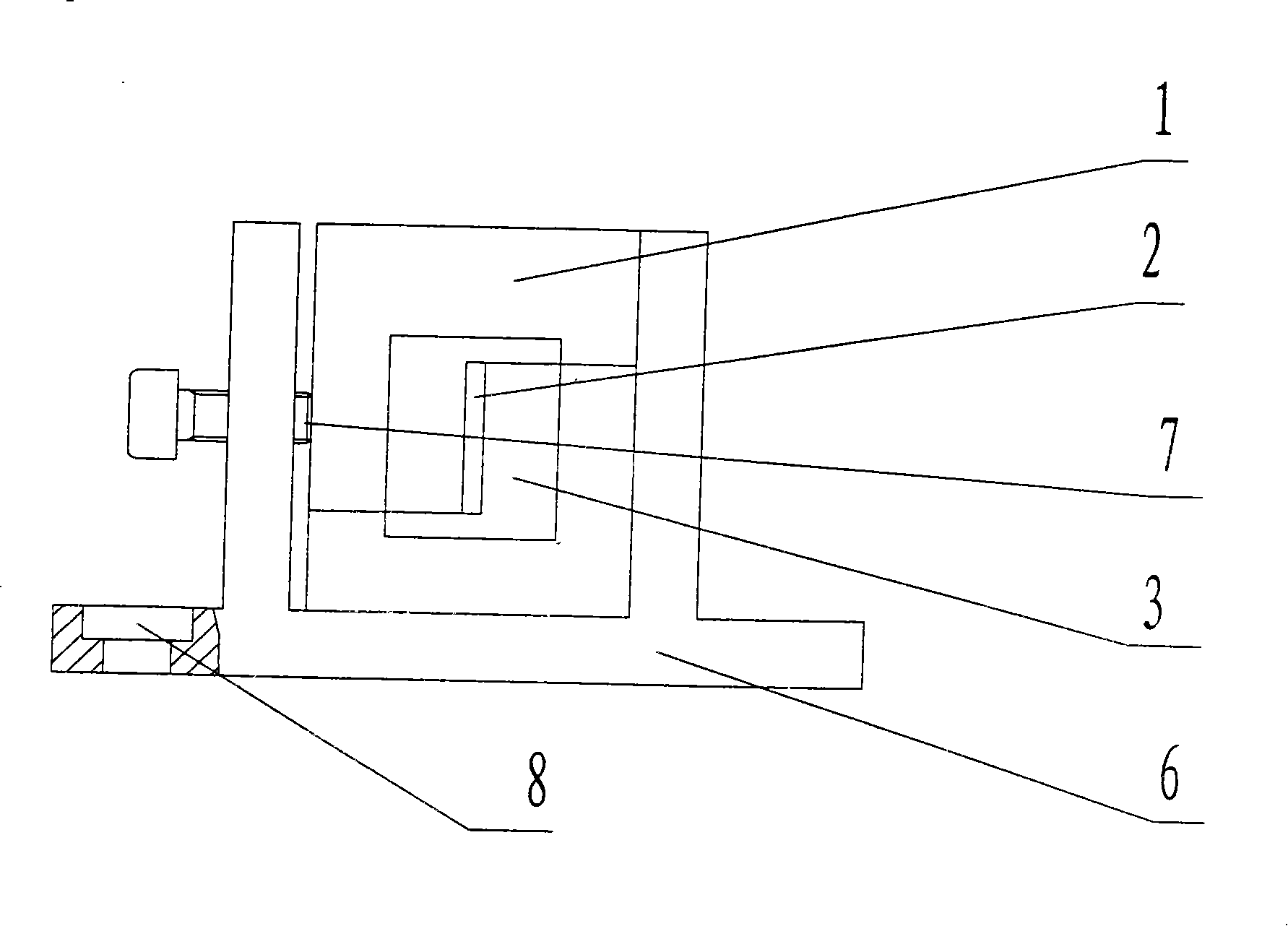

[0028] Embodiment 1: see figure 1 , figure 2 , an X-ray collimator device, comprising a base 6, characterized in that: a fixedly connected slit body 1 is set on the base 6, and a straight slit 2 is set in the slit body 1.

[0029] The above-mentioned slit 2 is a rectangular slit.

[0030] The above-mentioned slit main body 1 is interlacedly fastened by the inner fastening surface 10 and the outer fastening surface 11 of the overall L-shaped upper fastener 1-1 and the lower fastener 1-2 along the direction of the optical path, and is positioned at both ends. The pin 4 and the positioning screw 5 are fixedly formed, and its shape is a cuboid; the slit 2 is between the inner surface 9 of the upper fastener 1-1 and the lower fastener 1-2 and the inner fastening surface 10 gap between.

[0031] The center line of the slit 2 is located at the center of the slit body 1 .

[0032] A boss 3 is provided at one end of the above-mentioned slit main body 1, and the boss 3 is composed ...

Embodiment 2

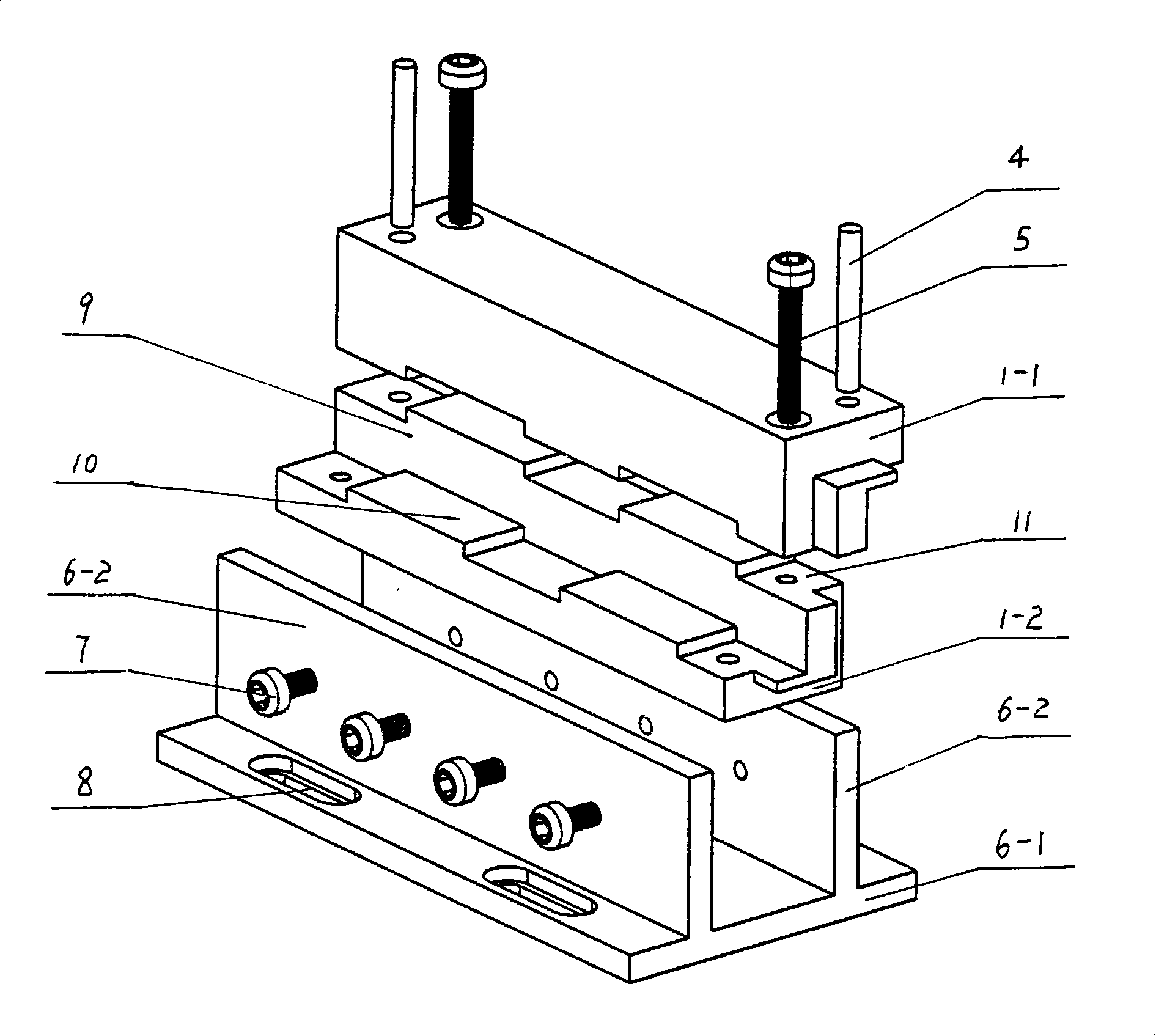

[0034] Example 2: see image 3 , Figure 4The structure difference between this embodiment and embodiment 1 is that: the inner fastening surface 10 and the outer fastening surface 11 of the upper fastener 1-1 and the lower fastener 1-2 are along the The concave-convex stepped surface with mutually matched optical path directions has two concave-convex fastening surfaces.

[0035] Other structures are the same as in Embodiment 1.

Embodiment 3

[0036] Embodiment 3: see Figure 5 , Figure 6 , the structure difference between this embodiment and embodiment 1 is: the slit 2 is a cylindrical circular hole slit; the slit body 1 is composed of an integral rectangular upper fastener 1-1 and a lower fastener 1-2 is buckled along the direction of the light path, and fixed by positioning pins 4 and positioning screws 5 at both ends, and its shape is a cuboid; the slit 2 is formed by the upper fastener 1-1 and the The lower fastener 1-2 is formed by fastening the corresponding semicircular arc surface on the fastening surface. The fastening surface of the upper fastener 1-1 and the lower fastener 1-2 is a concave-convex stepped surface that cooperates with each other along the optical path direction, the number of the concave-convex fastening surface is one, and the concave-convex stepped surface The height is greater than the radius of the circular hole slit, and an opening is arranged on the convex step surface above the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com