Method for preparing electroconductive particles with improved dispersion and adherence

A dispersive and adsorbent technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of difficult removal of aggregation phenomenon, complicated process, high cost, etc., to reduce the operating cost of the program , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] According to the present invention, the method for preparing conductive powder with excellent dispersibility and adsorption property will be described in detail in the following description.

[0042] However, the following examples do not limit the spirit of the present invention.

Embodiment 1

[0044] (Pre-treatment process of nickel plating)

[0045] The acryl based powder used had an average particle diameter of 3.6 μm, an aspect ratio of 1.06 and a vibration coefficient (Cv) of 5%. Disperse 5 g of powder in chromium oxide (CrO 3 ) and sulfuric acid in a mixed solution, followed by an ultrasonic cleaner for 30 minutes. After the above steps are completed, the powder is subjected to precipitation at a temperature of 60° C. for ten minutes, and then washed with deionized water. After cleaning, in tin dichloride (SnCl 2 ) in an aqueous solution (0.1 g / l) for three minutes. After precipitation, wash with cold deionized water. Next, in palladium dichloride (PdCl 2 ) aqueous solution (0.1 g / l) for three minutes, and then washed several times with cold deionized water, finally a slurry can be obtained.

[0046] (nickel plating process)

[0047] Phosphate (NaH 2 PO 2 ) aqueous solution as a dispersion liquid, the solution is heated to a temperature of 60° C., and ...

Embodiment 2

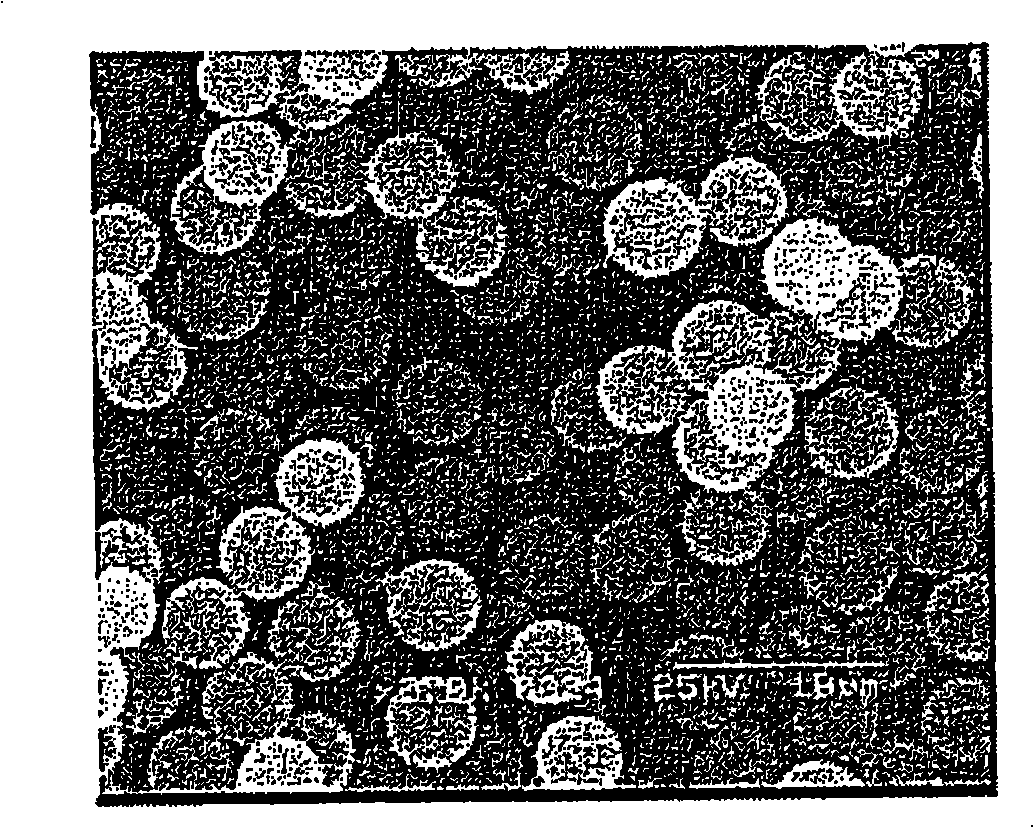

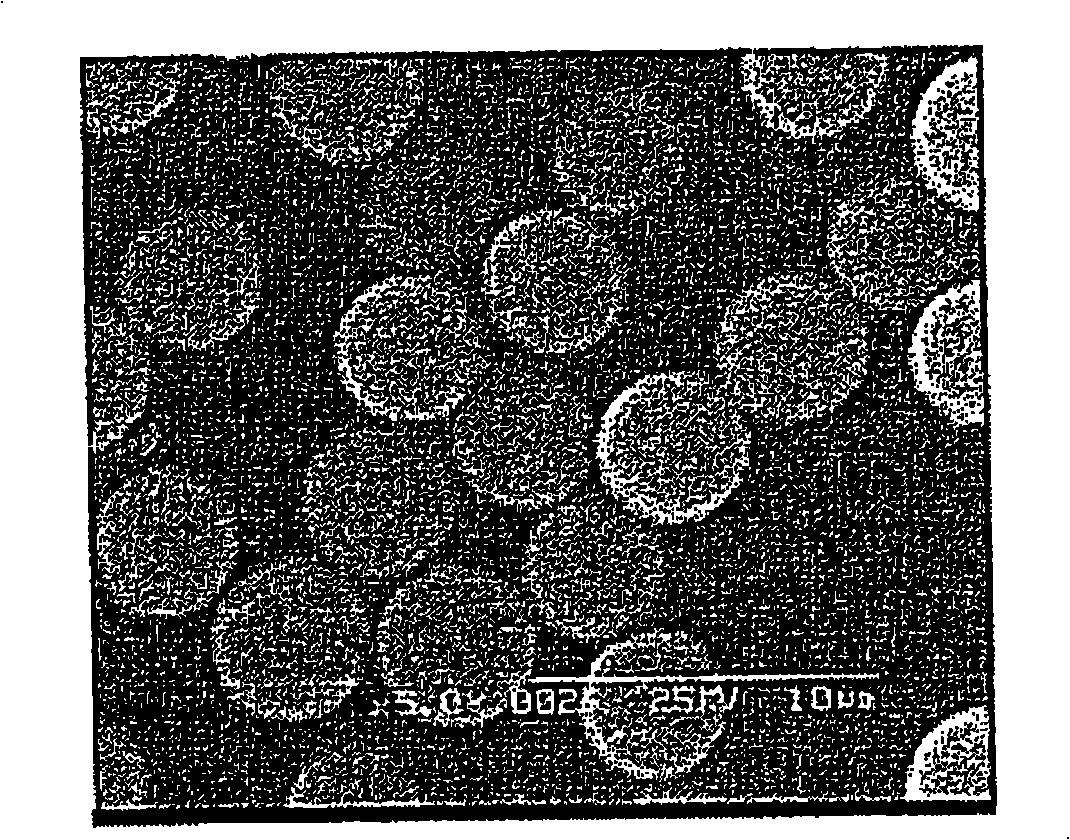

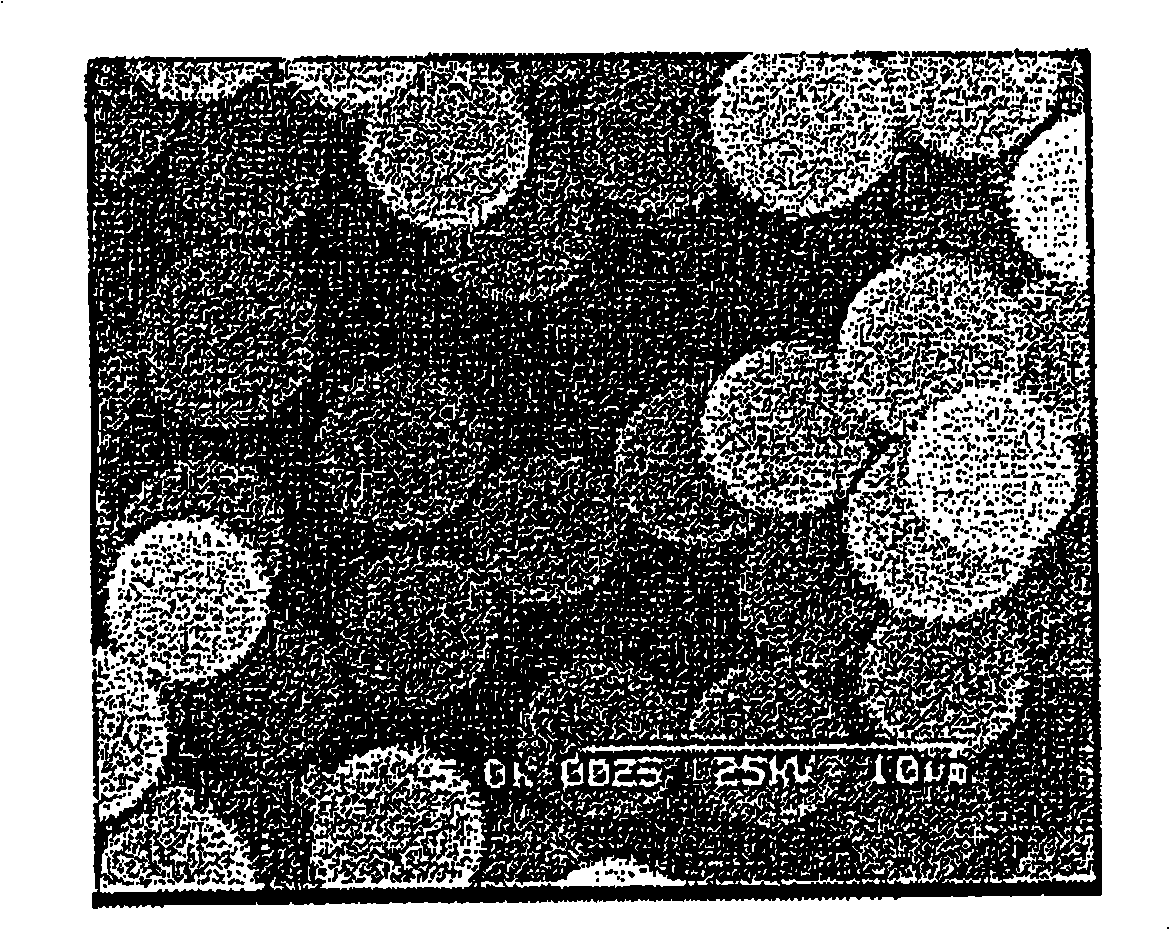

[0065] The pretreatment process carried out is the same as in Example 1, and the electroplating procedure is the same as in Example 1, except that 0.5g of polyethylene glycol (polyethyleneglycol) (molecular weight 20,000) is added in the electroplating procedure, which is a reduction Compounds with surface tension. The dispersibility, conductivity, density and adhesion of the prepared nickel electroplating powder are listed in Table 1 below. Photos of plating uniformity taken with a scanning electron microscope show the figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com