Pollution control device for preventing harmful gas from being short circuited

A harmful gas and pollution control technology, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as ineffectiveness, loss of balance in the system, failure to achieve the effect of pollution control, etc. Simple and effective for improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

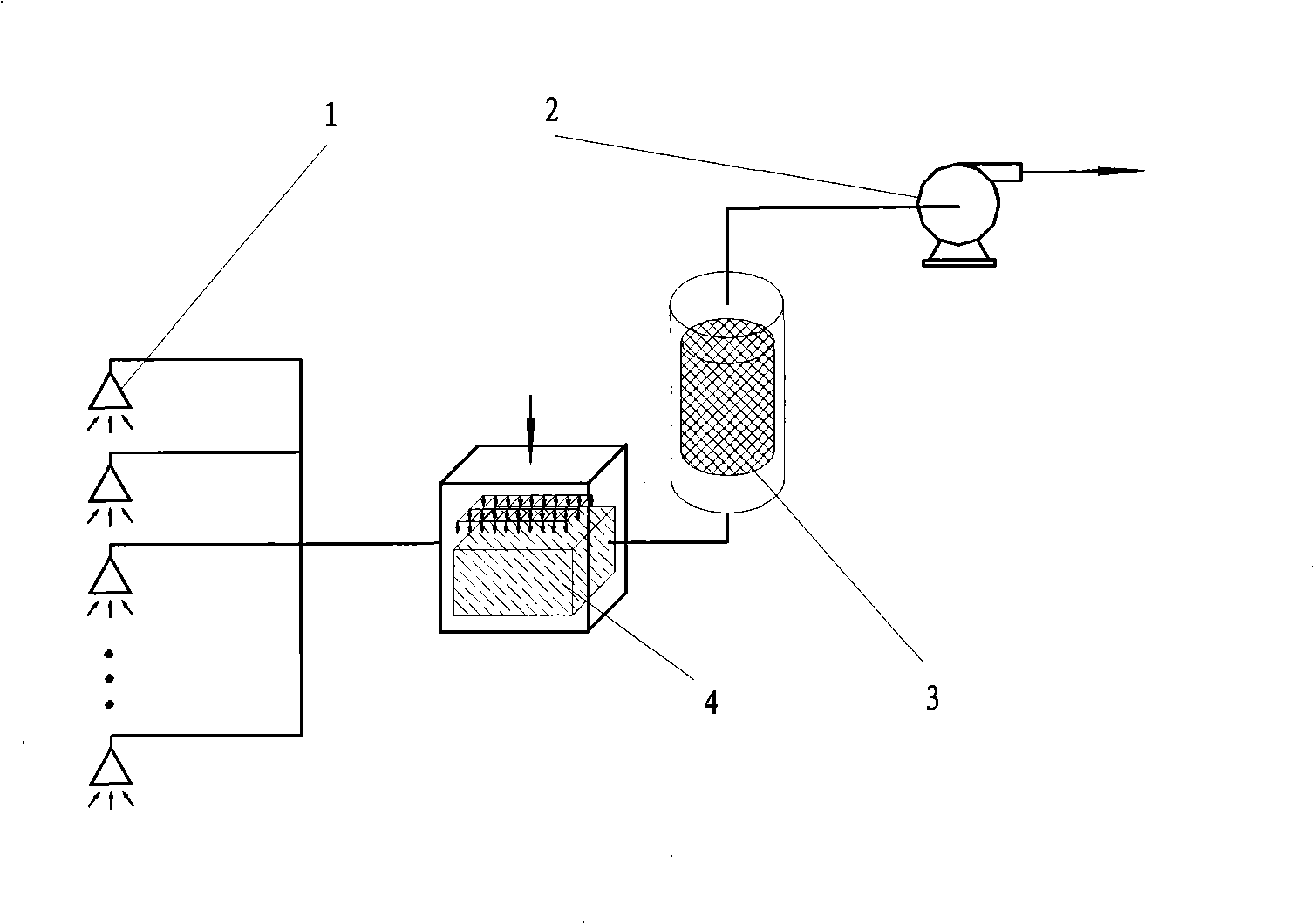

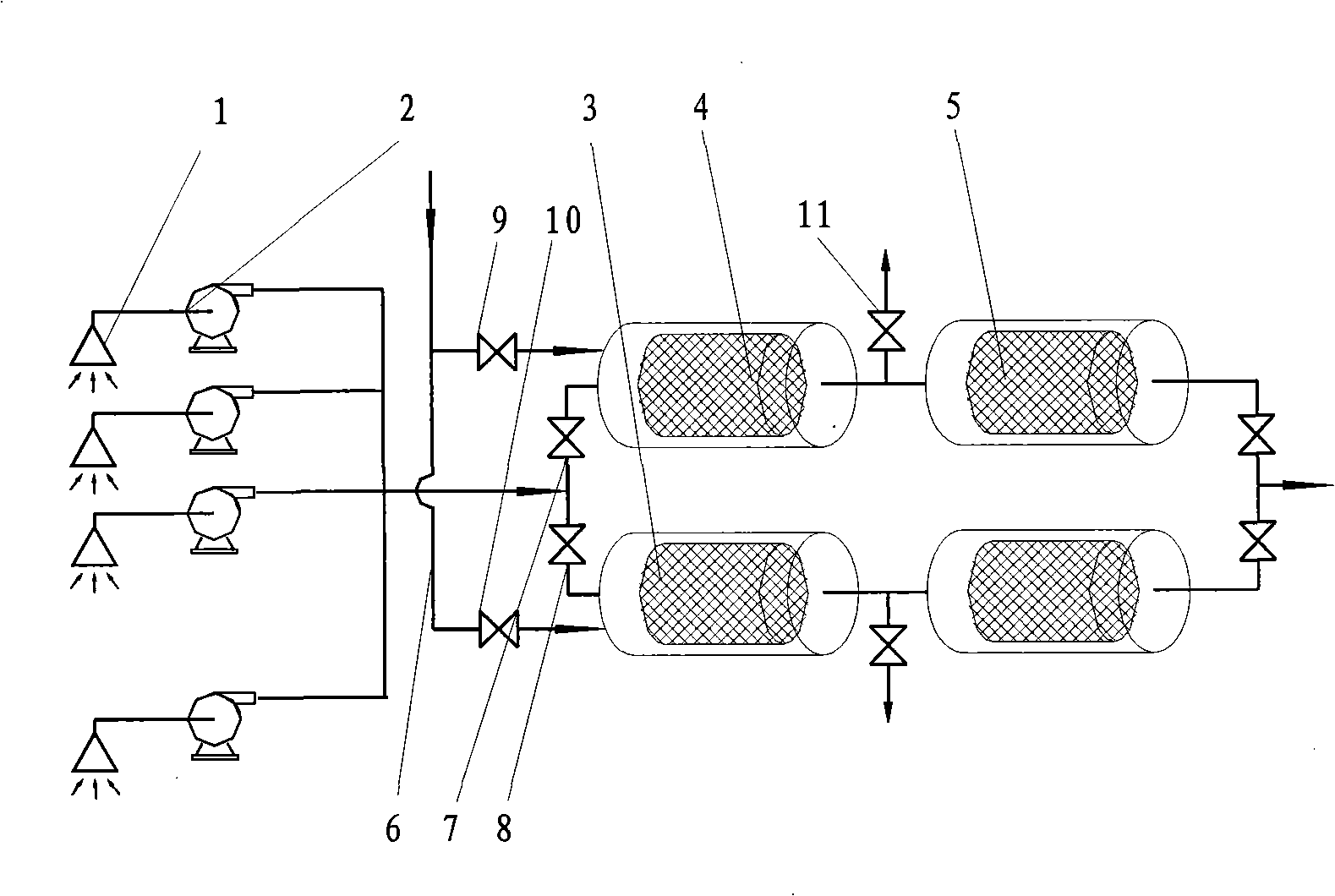

[0020] The pollution control device for preventing short circuit of organic solvent gas of the present invention is applied in the production workshop of a chemical factory mainly producing acrylic acid monomers, resins for dyeing and finishing, auxiliary agents, etc. The production workshop inevitably produces and emits volatile organic compound gases during the process of feed synthesis reaction, filtration and packaging. figure 1 The concentration of harmful organic solvent gases measured at the vent of the pollution control system shown is 1500 ppm. Such as figure 2 As shown, utilize the device of the present invention to carry out transformation, set suction hood mouth 1 respectively at 8 gas discharge ports, 8 suction hood mouths 1 connect axial flow fan 2 respectively (each suction mouth is all correspondingly provided with an axial flow fan ), the pipeline connecting the suction fan 2 is connected in parallel with one of the activated carbon adsorbers 3 and two of th...

Embodiment 2

[0022] The pollution control device for preventing short-circuiting of organic solvent gases of the present invention is applied in a laboratory that produces volatile organic solvent gases such as toluene, ethyl acetate, xylene, styrene, and methanol. In a test, the concentration of organic solvent gas at the suction port was 800ppm. Such as figure 2 As shown, install the pollution control device of the present invention to prevent the organic solvent gas from short-circuiting, respectively set the suction cover ports 1 at the 5 gas discharge ports, and the 5 suction cover ports 1 are respectively connected to the axial flow fan 2 and connected to the suction fan 2. After the pipelines are connected in parallel, they are respectively connected with one of the activated carbon adsorbers 3 and the second of the activated carbon adsorbers 4, and the first of the activated carbon adsorbers 3 and the second of the activated carbon adsorbers 4 are respectively connected with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com