Double arc four wire automatic arc-submerging welder and manufacture method thereof

A submerged arc welding machine and automatic technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of low welding efficiency, high labor intensity, and high operating height, so as to improve welding efficiency and reduce Labor intensity, the effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

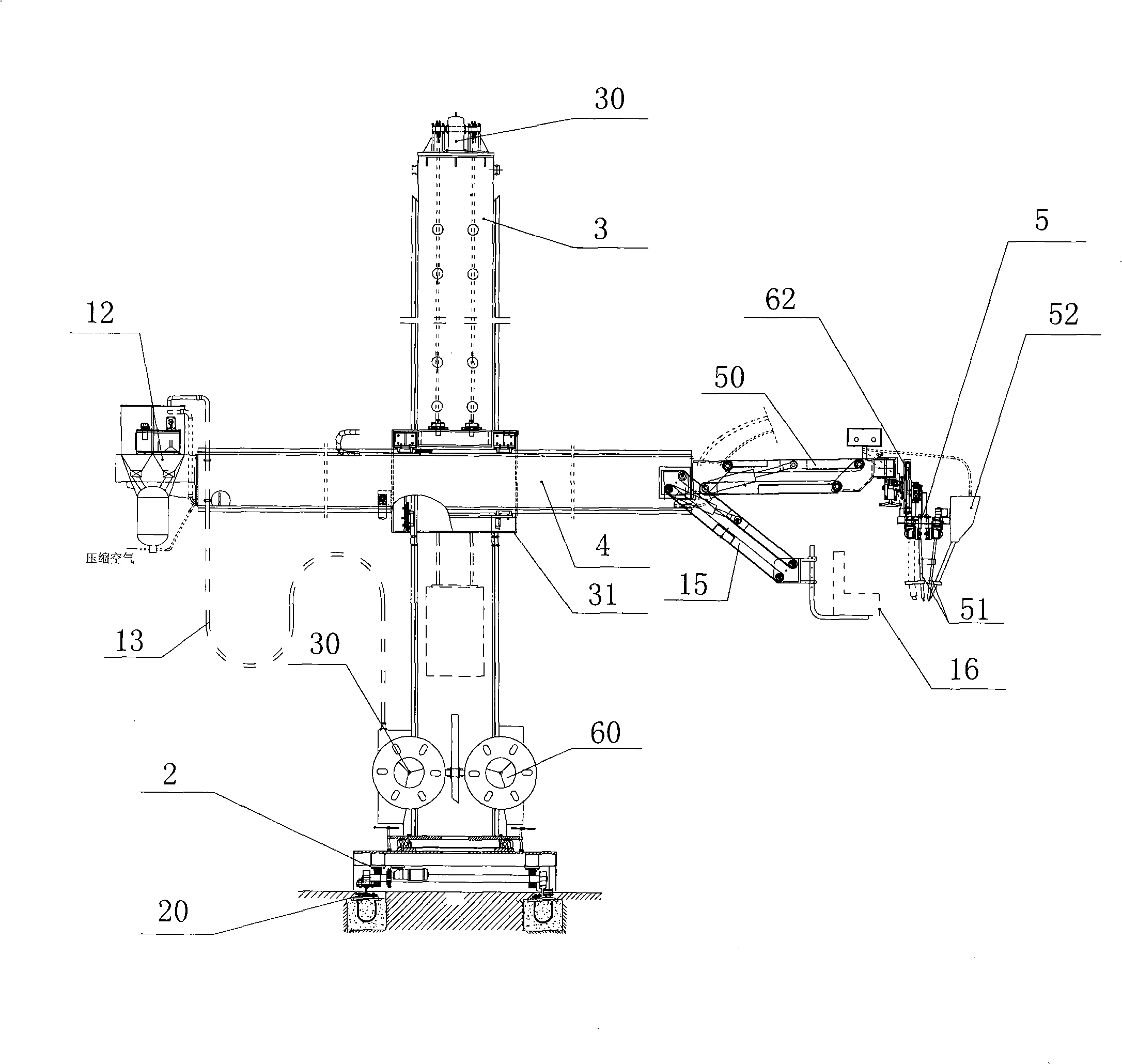

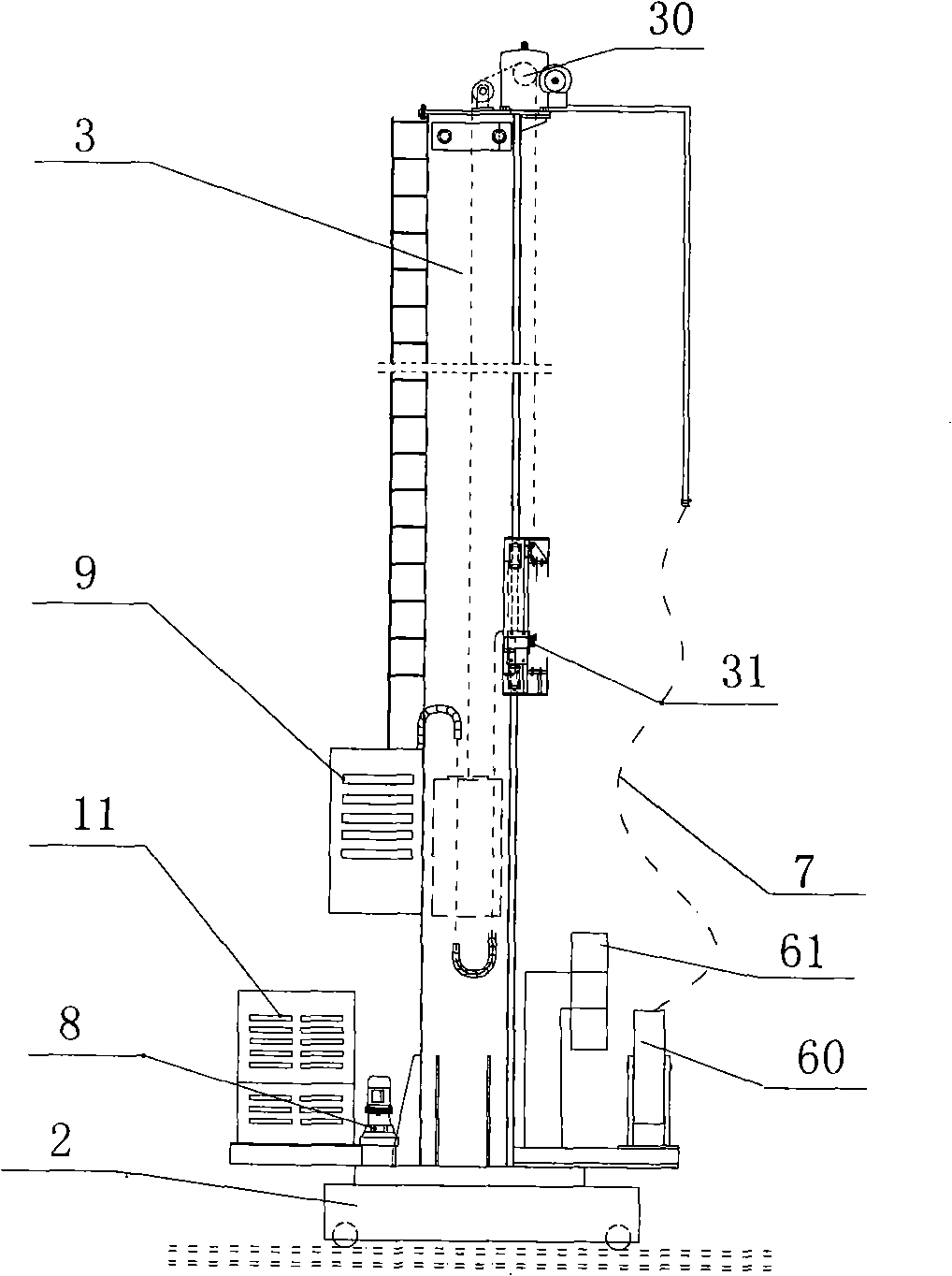

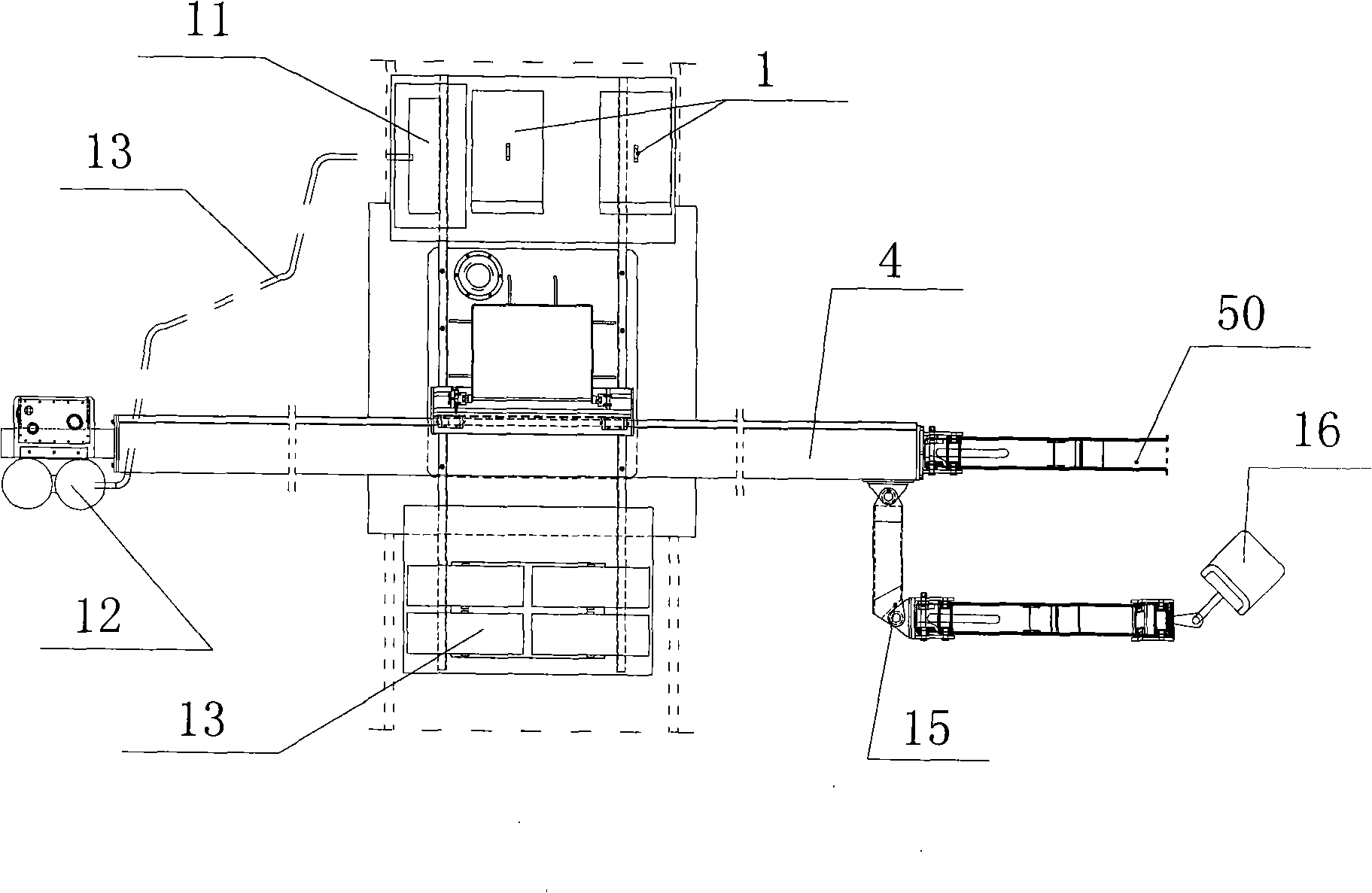

[0030] see figure 1 , 2 , 3, a kind of double-arc four-wire automatic submerged arc welding machine of the present invention, comprises welding power source 1, trolley and walking device 2, column 3, cross arm 4, welding machine head 5, wire feeding mechanism, guide wire tube 7 , Slewing mechanism 8 and electric control cabinet 9. in,

[0031] The welding power source 1 is two inverter power sources AC / DC1000, which are arranged behind the column 3 and connected to the side wall of the column 3 .

[0032] The trolley and the running device 2 can move linearly and horizontally through the guide rail 20 provided on the ground.

[0033] The top of the column 3 is provided with a lifting mechanism 30 and is located on the trolley and the running gear 2 .

[0034] The cross arm 4 is movably connected with the lifting mechanism 30 through a slide plate 31 and can move up and down along the column 3, and its vertical lifting effective stroke is 6000mm.

[0035] A welding torch 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com