Low zirconium and fluoride type alkaline sintering welding agent for ship and preparation method thereof

A technology of zirconium fluorine alkali type and sintered flux, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of low-temperature toughness of welded joints to be improved, poor process performance, poor moisture absorption resistance, etc., and achieve slag removal Good, meet the process requirements, smooth weld bead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

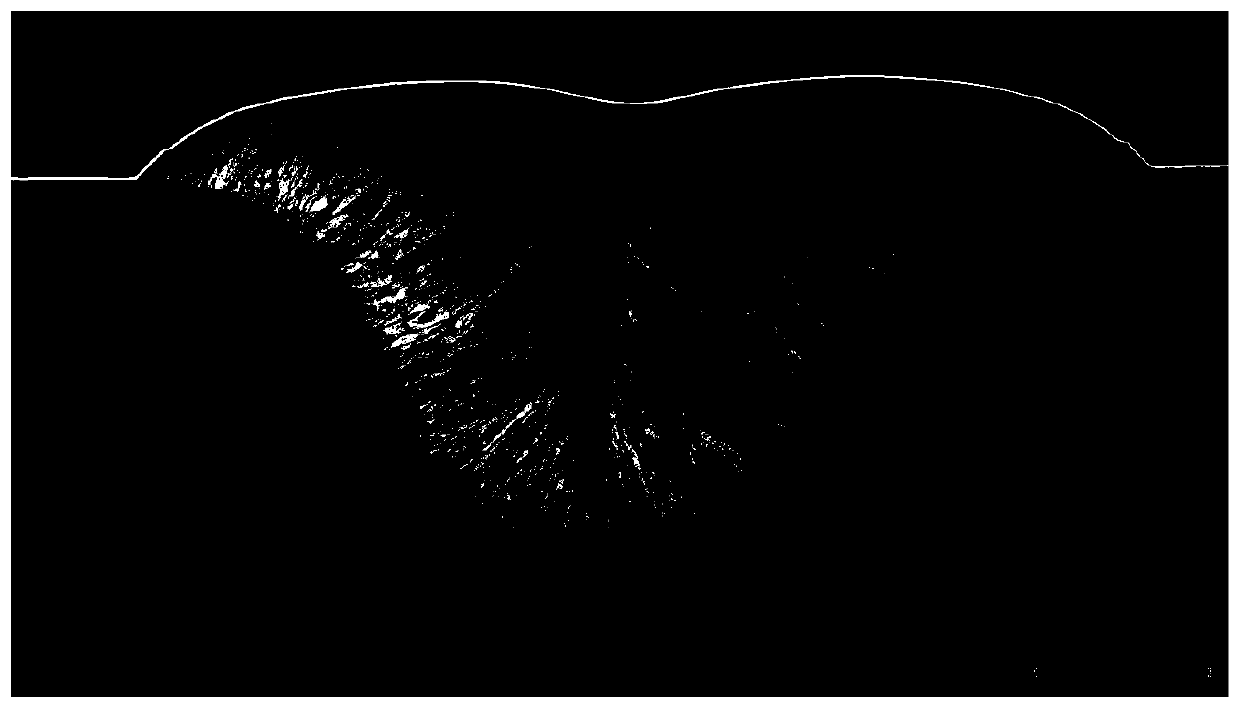

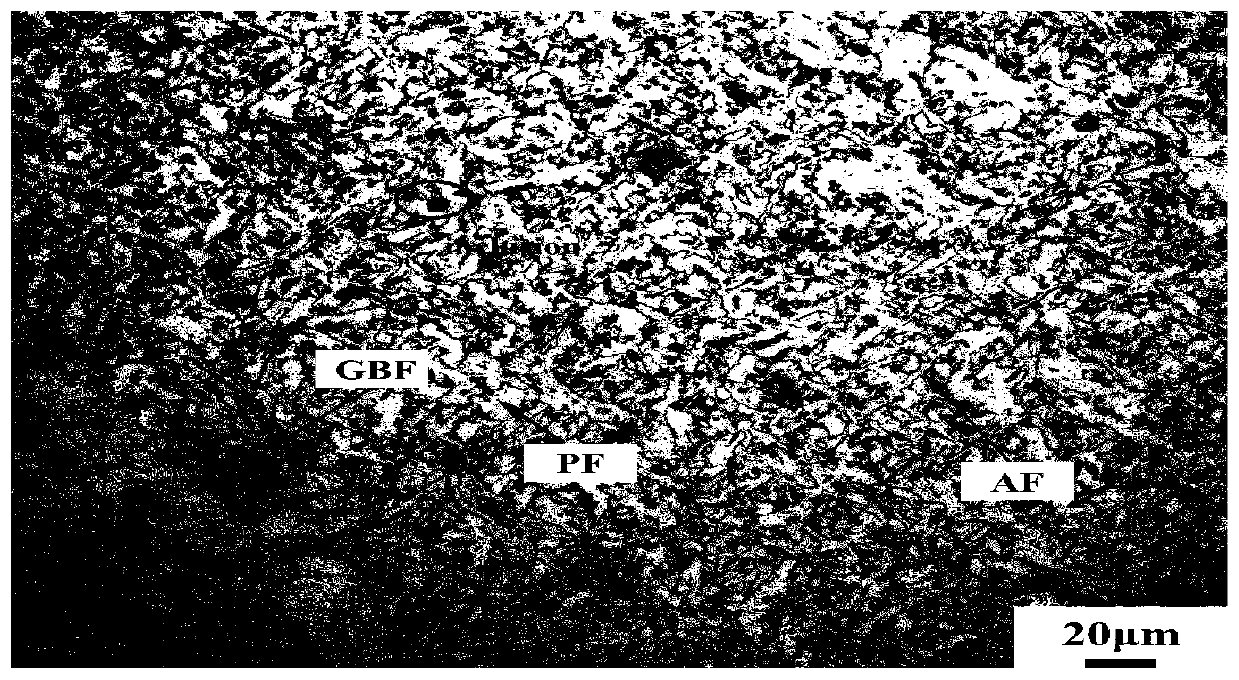

Image

Examples

Embodiment 1

[0040] A kind of marine low zirconium fluorine alkali type sintered flux, which contains components by mass percentage: CaF 2 : 97%, ZrO 2 : 3%.

[0041] The preparation method of marine low-zirconium fluorine alkali type sintered flux of the present invention comprises the steps:

[0042] Step 1, mixing ingredients:

[0043] (1) According to the composition ratio of the marine low-zirconium fluoride alkali-type sintered flux, after weighing each raw material, put it into a mixing device, stir evenly, and obtain a dry-blended raw material;

[0044] (2) by mass ratio, water glass: dry mixing raw material=20%, water glass and dry mixing raw material are carried out wet mixing, make wet mixing material; Wherein, water glass is sodium water glass;

[0045] Step 2, granulation:

[0046] (1) The wet mixture is granulated once, and the particles with a particle size of 16 to 50 mesh are selected as semi-finished products;

[0047] (2) Crushing the particles with a particle size ...

Embodiment 2

[0053] A kind of marine low zirconium fluorine alkali type sintered flux, which contains components by mass percentage: CaF 2 : 95%, ZrO: 5%.

[0054] The preparation method of marine low-zirconium fluorine alkali type sintered flux of the present invention comprises the steps:

[0055] Step 1, mixing ingredients:

[0056] (1) According to the composition ratio of the marine low-zirconium fluoride alkali-type sintered flux, after weighing each raw material, put it into a mixing device, stir evenly, and obtain a dry-blended raw material;

[0057] (2) by mass ratio, water glass: dry mixing raw material=15%, water glass and dry mixing raw material are carried out wet mixing, make wet mixing material; Wherein, water glass is potassium water glass;

[0058] Step 2, granulation:

[0059] (1) The wet mixture is granulated once, and the particles with a particle size of 16 to 50 mesh are selected as semi-finished products;

[0060] (2) Crushing the particles with a particle size g...

Embodiment 3

[0066] A kind of marine low zirconium fluorine alkali type sintered flux, which contains components by mass percentage: CaF 2 : 94%, ZrO 2 : 6%.

[0067] The preparation method of marine low-zirconium fluorine alkali type sintered flux of the present invention comprises the steps:

[0068] Step 1, mixing ingredients:

[0069] (1) According to the composition ratio of the marine low-zirconium fluoride alkali-type sintered flux, after weighing each raw material, put it into a mixing device, stir evenly, and obtain a dry-blended raw material;

[0070] (2) by mass ratio, water glass: dry mixing raw material=20%, water glass and dry mixing raw material are carried out wet mixing, make wet mix; Wherein, water glass is sodium water glass and potassium water glass by mass ratio 1:1 mixed;

[0071] Step 2, granulation:

[0072] (1) The wet mixture is granulated once, and the particles with a particle size of 16 to 50 mesh are selected as semi-finished products;

[0073] (2) Crush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com