Multiple layer inlaid thread machine knitting and knitting compound structures and its weaving method and special equipment

A composite structure and knitting technology, which is applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of small fabric thickness and application limitations, and achieve the effect of simple device structure, flexible weaving method and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

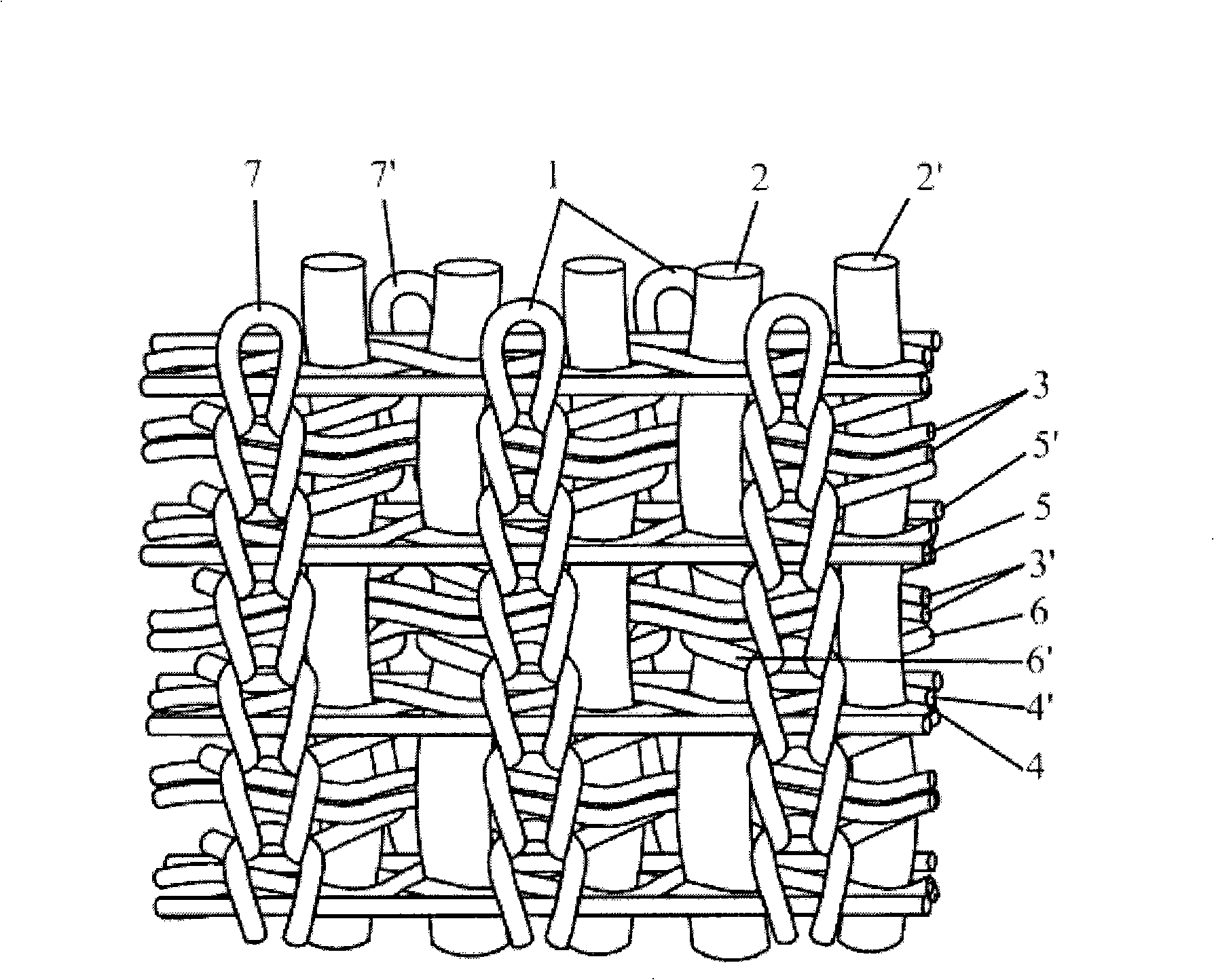

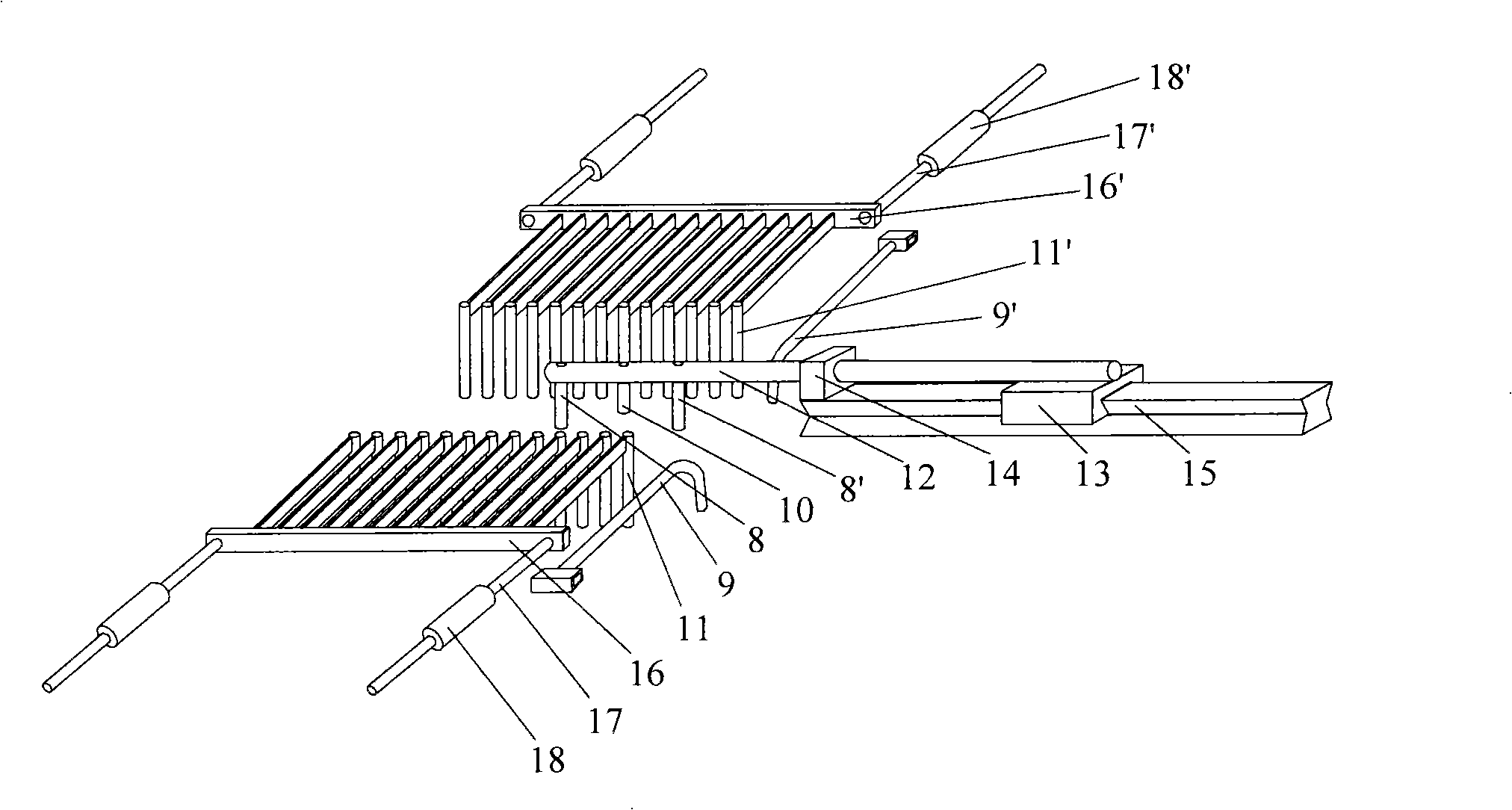

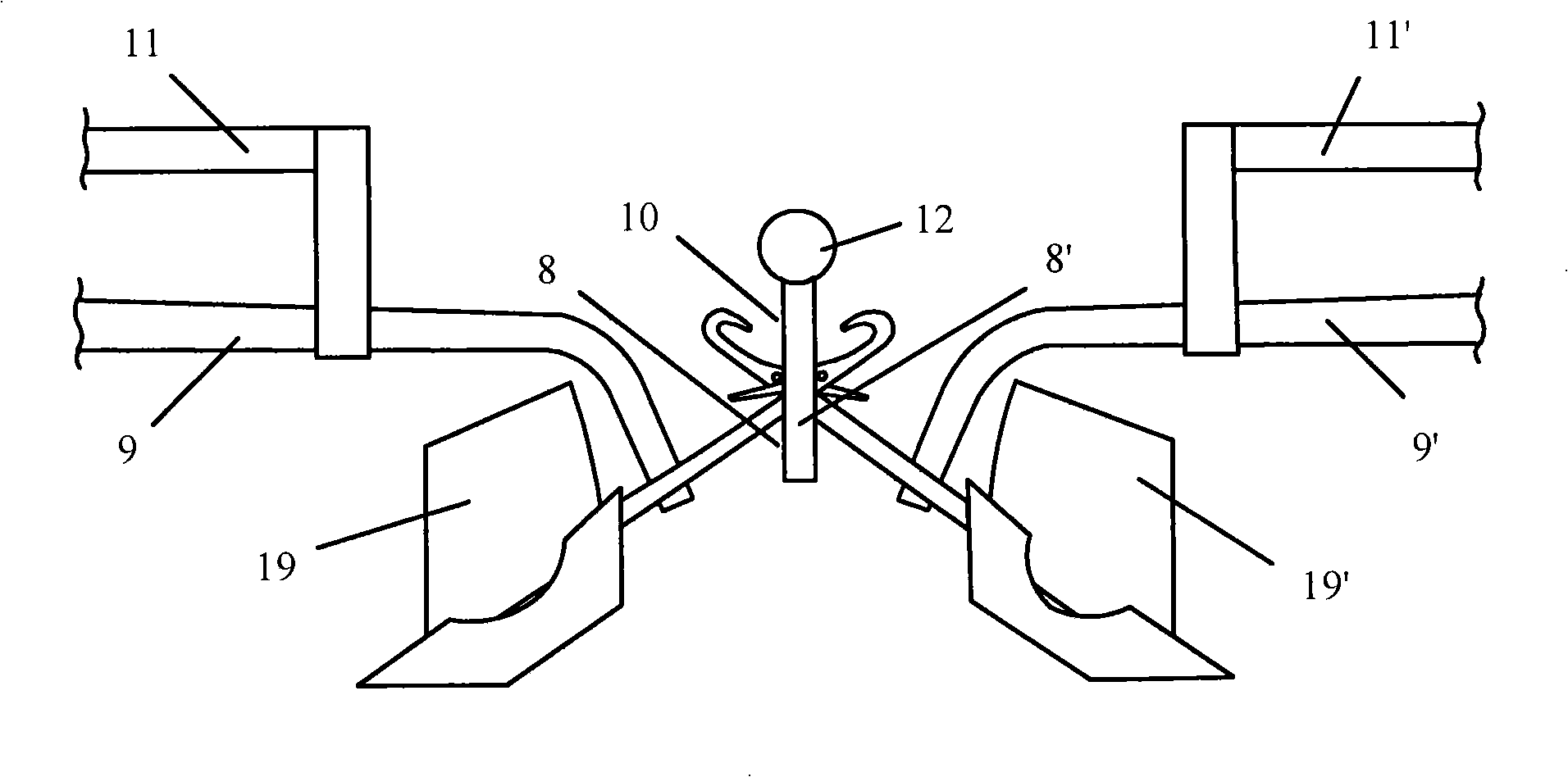

[0035] The present invention will be described in detail below with reference to the accompanying drawings, by figure 1 It can be seen that the multi-layer weft-inserted woven and knitted composite structure of the present invention includes 1+1 rib weave 1, two sets of warp yarns 2 and 2' and multi-layer weft yarns 3, 3', 4, 4', 5, 5'; 2 and 2' appear alternately in the front and back of sinker loops 6 and 6' in rib weave 1 every two rows; weft yarns 3, 3', 4, 4', 5, 5' are clamped on the front of rib weave 1 Between wale 7 and reverse wale 7'; weft yarns 3 and 3' appear alternately every other two courses, and weft yarns 4, 4', 5, 5' appear once every two courses at the same time; weft yarns 3 and 3 ' and weft yarns 4, 4', 5, 5' in alternating rows; weft yarns 3 and 4 are in front of warp yarn 2' and behind warp yarn 2, and weft yarns 3' and 4' are behind warp yarn 2' and in front of warp yarn 2 , Weft yarns 5 and 5' are located in front and behind of warp yarns 2 and 2' re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com