Method and its system for controlling photolithography exposure dosage

A technology of exposure dose and lithography, which is applied in the field of lithography machines, can solve the problems of multiple equipment and complex structure, and achieve the effect of simple system structure, simple algorithm, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

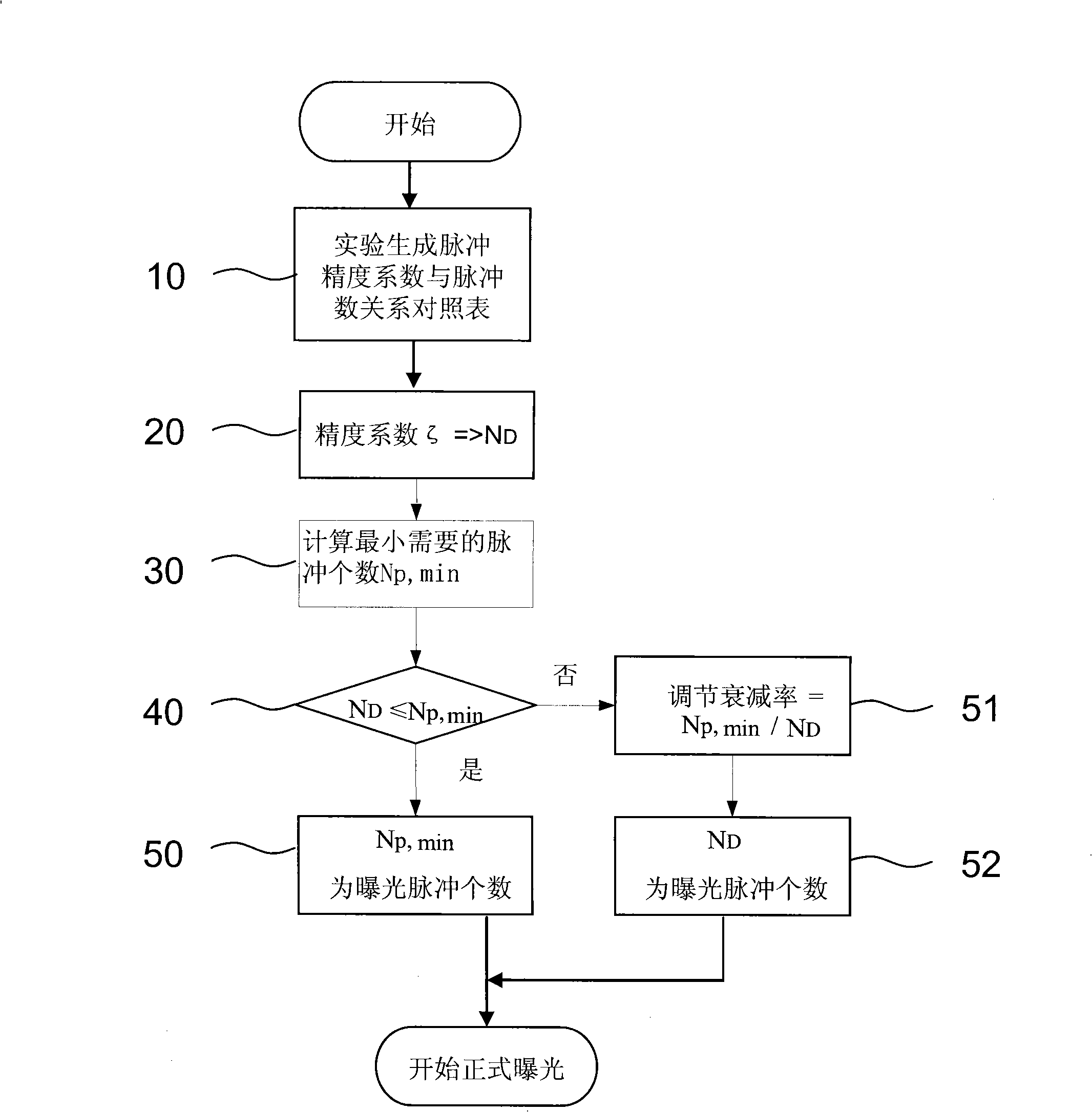

[0036] figure 1 Shown is a flow chart of an embodiment of a method for controlling exposure dose of lithography provided by the present invention. Such as figure 1 As shown, the process steps include:

[0037] Step 10: Experimentally generate a pulse precision coefficient and pulse number relationship comparison table;

[0038] Further, perform step 20: according to the coefficient ζ required by the exposure accuracy, look up the number of pulses N from the relationship comparison table in step 10 D ;

[0039] Further, perform step 30: calculate the actual required number of pulses Np,min according to the unattenuated single pulse dose and the ideal required exposure dose;

[0040] Further, perform step 40: for the number of pulses N D Compare with Np and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com