Method for connecting printed circuit boards

A technology of printed circuit board and connection method, which is applied in the direction of printed circuit, printed circuit, structural connection of printed circuit, etc., can solve the problems of unrealized connection, high connection resistance, drop, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

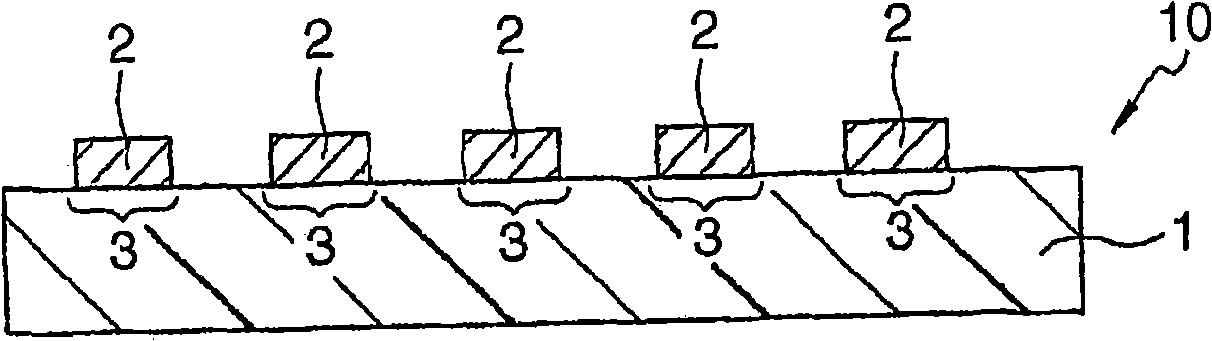

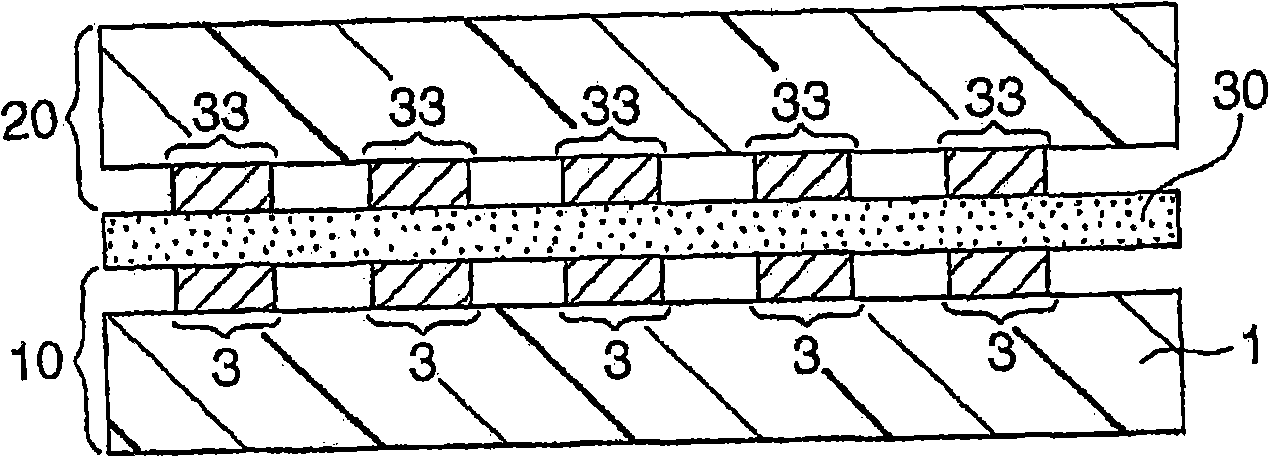

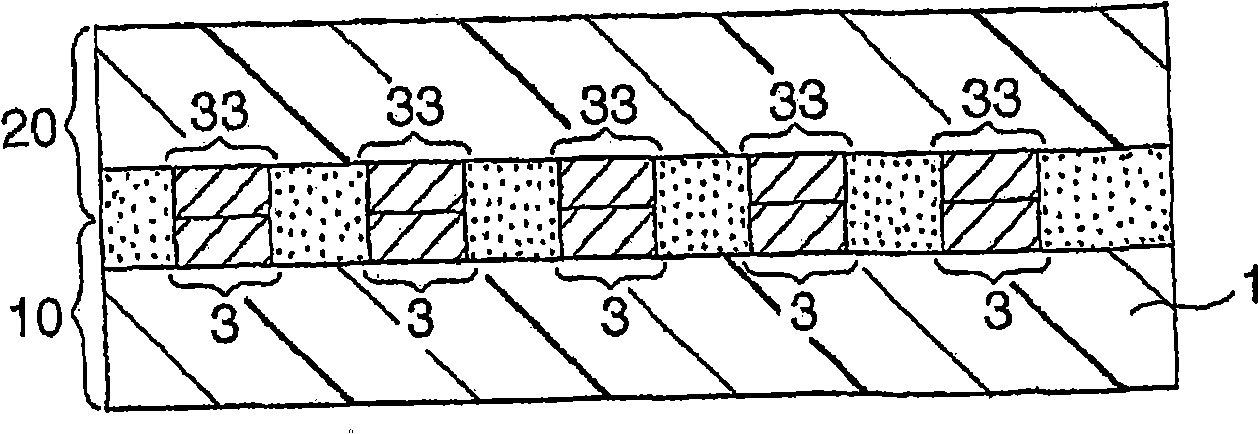

[0045] 1. Preparation of Rigid Circuit Board (PCB) and Flexible Printed Circuit Board (FPC)

[0046] Rigid circuit boards (PCBs) and flexible printed circuit boards (FPCs) were prepared as follows.

[0047] PCB: base material: FR-4 (0.4mm), metal wiring: gold / nickel / copper=0.3μm / 5μm / 18μm

[0048] Wiring width (L) / distance between wiring (S) = 100μm / 100μm, 50 circuits

[0049] FPC: base material: polyimide (25μm), metal wiring: gold / nickel / copper = 0.3μm / 1.5μm / 18μm

[0050] Wiring width (L) / distance between wiring (S) = 100μm / 100μm, 50 circuits

[0051] Projections were formed on the circuit surface of the flexible printed circuit board by pressing with a mold having the following form.

[0052] Die: SKD-11, commercially available from Ohtake Seisakusho K.K., Gifu-ken, Japan, comprising 8 linear grooves with 200 μm pitch, 30 μm height.

[0053] Pressing plate: wire bumps and flexible printed circuit board circuits are arranged orthogonally and pressed with a load of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com