Rare earth doping luminescent glass for white radiation LED and producing thereof

A technology of rare earth doping and luminescent glass, which is applied in the field of luminescent glass doped with rare earth ions for white LEDs, and can solve the problems of easy aging of epoxy resin, high cost, and easy drift of white light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

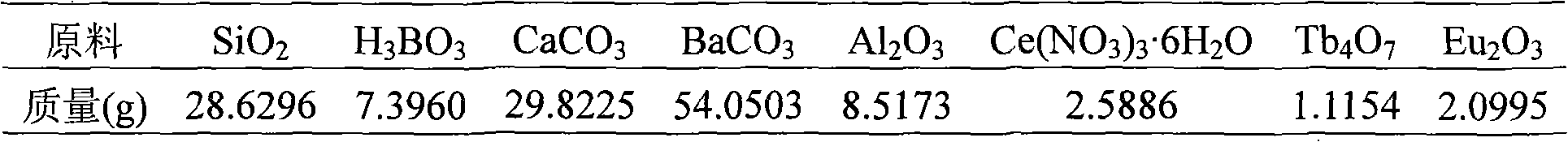

[0018] Using analytically pure CaCO 3 、BaCO 3 , SiO 2 、H 3 BO 3 、Al 2 o 3 and 99.99% Tb 4 o 7 、Eu 2 o 3 and Ce(NO 3 ) 3 ·6H 2 O is the main raw material, according to 40SiO 2 5B 2 o 3 25CaO 23BaO 7Al 2 o 3 :0.25Ce 2 o 3 0.125Tb 2 o 3 0.5Eu 2 o 3 (mol%) composition takes batching material 100g, and each raw material quality is as shown in table 1:

[0019] The glass composition mol% of table 1 embodiment 1 (SCB 3)

[0020]

[0021] After accurate weighing, mix in a V-blender for 4 hours. The batch is placed in a corundum crucible and firstly kept at 550°C for 1.5 hours, and then placed in an electric furnace at 1550°C for 3 hours. The molten glass is poured into a preheated mold and annealed at 600°C for 3 hours to obtain SCB3. The excitation spectrum of the glass is 376nm, and the main emission wavelengths of the three rare earth ions are Ce 3+ : 488nm, Tb 3+ : 542nm and Eu 3+ : 612nm, the relative intensity ratio (R:G:B) is: 0.62:1:1.01, the co...

Embodiment 2

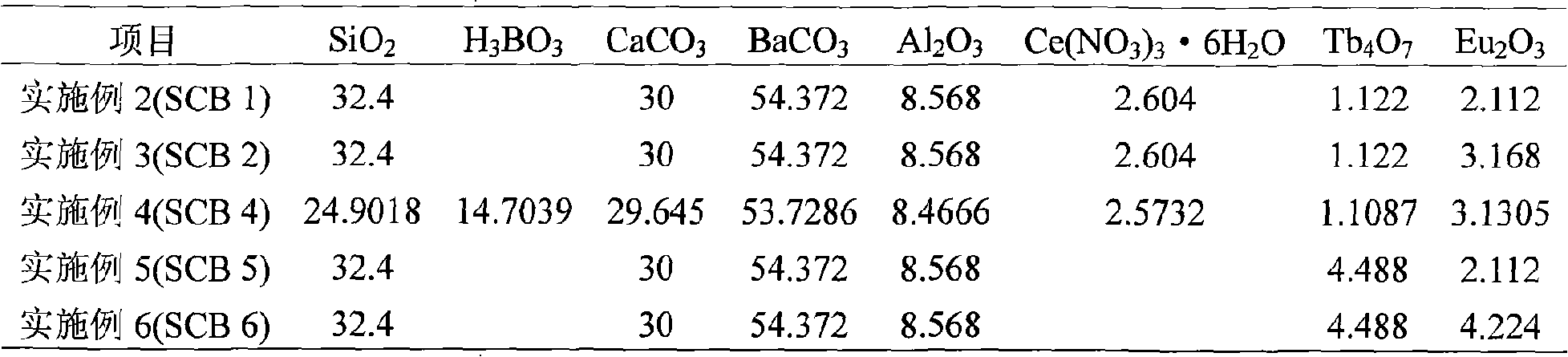

[0023] Example 2 (SCB 1): 45SiO 2 25CaO 23BaO 7Al 2 o 3 :0.25Ce 2 o 3 0.125Tb 2 o 3 0.5Eu 2 o 3 , Example 3 (SCB 2): 45SiO 2 25CaO 23BaO 7Al 2 o 3 :0.25Ce 2 o 3 0.125Tb2 o 3 0.75Eu 2 o 3 , Example 4 (SCB 4): 35SiO 2 10B 2 o 3 25CaO 23BaO 7Al 2 o 3 :0.25Ce 2 o 3 0.125Tb 2 o 3 0.75Eu 2 o 3 , Example 5 (SCB5): 45SiO 2 25CaO 23BaO 7Al 2 o 3 :0.5Tb 2 o 3 0.5Eu 2 o 3 , Example 6 (SCB6): 45SiO 2 25CaO 23BaO 7Al 2 o 3 :0.5Tb 2 o 3 1.0Eu 2 o 3 The preparation process of the medium-luminescent glass is similar to that of Example 1, and the total amount of batch materials is 100 g. The quality of each raw material and the luminescent performance parameters are shown in attached tables 1 and 2.

[0024] Schedule 1

[0025] Composition of Examples 2-6

[0026]

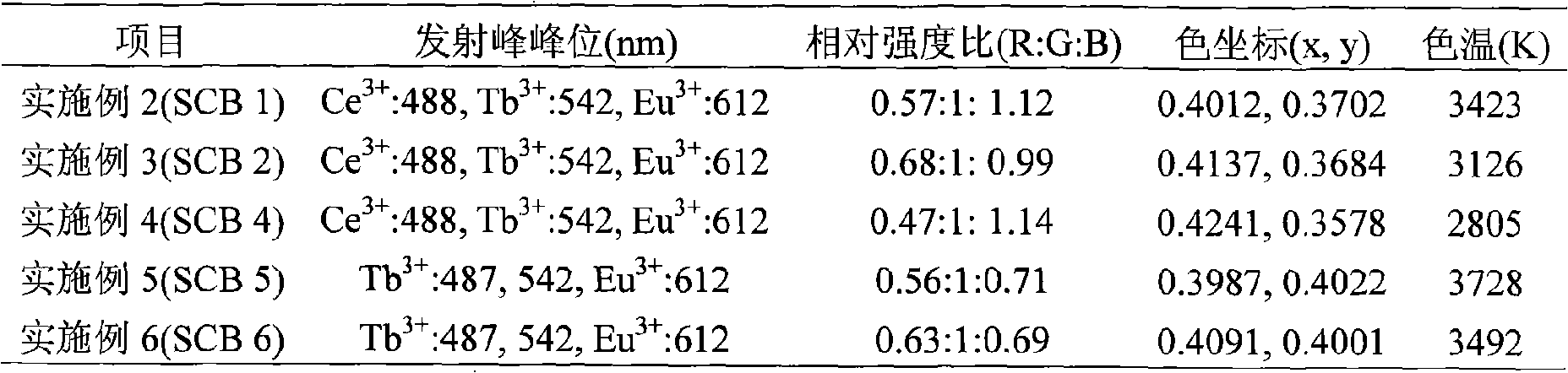

[0027] Schedule 2

[0028] The luminous performance parameter of embodiment 2-6

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com