Method for prepraring medicine carrying chitosan neural regeneration tube with controlled degradation

A technology of nerve regeneration and chitosan, which is applied in the field of preparation of nerve regeneration tubes, can solve the problems of high price and long-term administration of FK506, and achieve the effects of accelerating oriented growth and repair, avoiding long-term administration, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Select chitosan with a molecular weight of 800kD and a degree of deacetylation of 93%, and prepare an aqueous acetic acid solution containing chitosan with a concentration of FK506 of 0.1% (w / v), in which the concentration of chitosan is 7% (w / v), The concentration of acetic acid is 2% (v / v), ultrasonic degassing;

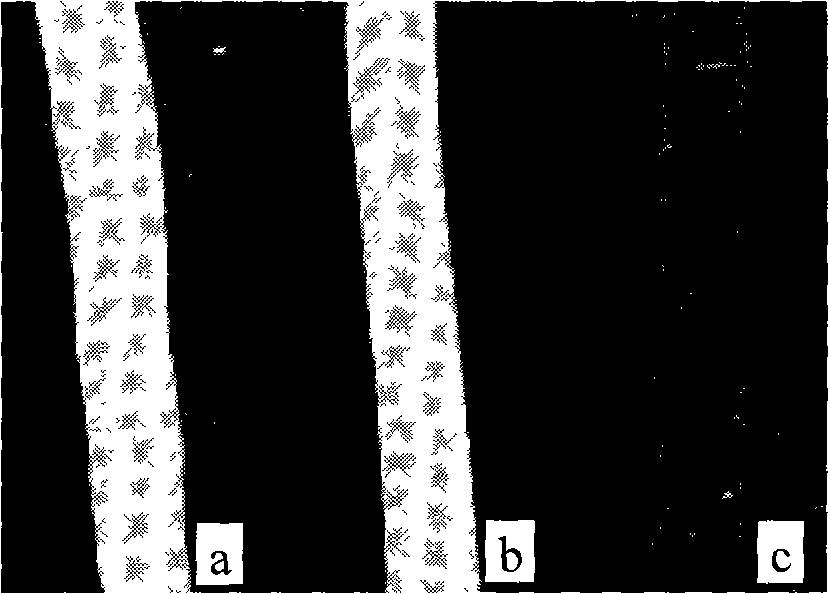

[0024] 2. Spread the gel solution evenly on the outer surface of a stainless steel rod with a diameter of 2mm, immerse it in a 1mol / L sodium hydroxide solution, take it out after 5 minutes, wash a lot of water until the pH of the lotion is neutral, and take out the mold to obtain a white drug-carrying shell polymer. Sugar gel, such as figure 1 shown in a;

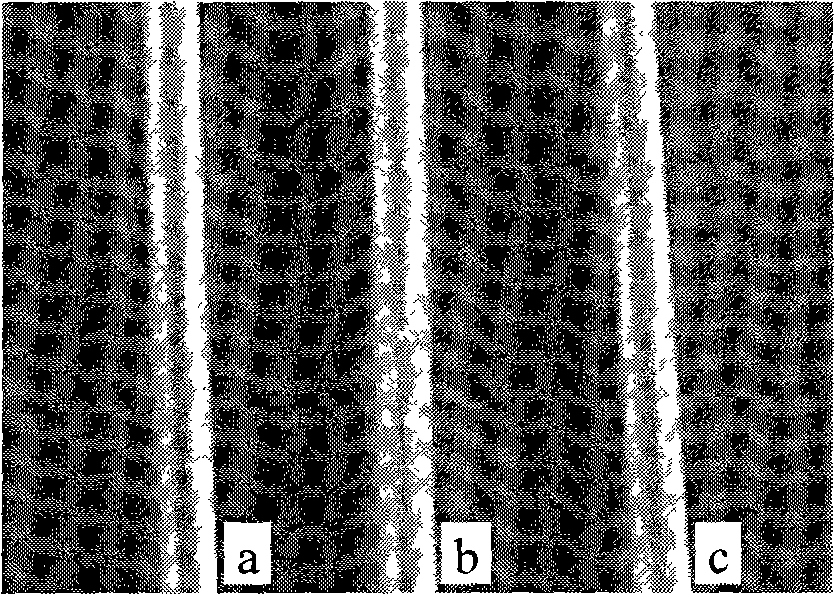

[0025] 3. Put the drug-loaded chitosan gel in the previous step on a stainless steel rod with a diameter of 1.8mm and dry it at 60°C for 30 minutes. Remove the mold and dry it naturally to obtain a drug-loaded chitosan nerve regeneration tube (such as figure 2 a);

[0026] 4. Application of drug-loaded c...

Embodiment 2

[0028] 1. Select chitosan with a molecular weight of 500kD and a degree of deacetylation of 80%, and prepare an aqueous acetic acid solution containing chitosan with a FK506 concentration of 1% (w / v), where the chitosan concentration is 4% (w / v), The concentration of acetic acid is 2% (v / v), ultrasonic degassing;

[0029] 2. Spread the gel solution evenly on the outer surface of a stainless steel rod with a diameter of 2mm, immerse it in a 0.1mol / L potassium hydroxide solution, take it out after 10 minutes, wash a lot of water until the pH of the lotion is neutral, take out the mold to obtain a translucent drug loading Chitosan gel (e.g. figure 1 b);

[0030] 3. Put the drug-loaded chitosan gel in the previous step on a stainless steel rod with a diameter of 1.8mm to dry naturally to obtain a drug-loaded chitosan nerve regeneration tube (such as figure 2 b);

[0031] 4. Application of drug-loaded chitosan nerve regeneration tube: 8 weeks after transplantation in Wister rats, the...

Embodiment 3

[0033] 1. Prepare an aqueous solution of acetic acid containing chitosan with a FK506 concentration of 4% (w / v), in which the chitosan concentration is 4% (w / v), the acetic acid concentration is 1% (v / v), and ultrasonic defoaming . The degree of deacetylation of chitosan is 70%, and the molecular weight is 200KD;

[0034] 2. Spread the gel solution evenly on the outer surface of a stainless steel rod with a diameter of 2mm, immerse it in a 2mol / L sodium hydroxide solution, take it out after 2 minutes, wash a large amount of water until the pH of the lotion is neutral, and take out the mold to obtain a transparent drug-carrying shell polymer. Sugar gel (e.g.figure 1 c);

[0035] 3. Put the drug-loaded chitosan gel in the previous step on a stainless steel rod with a diameter of 1.8mm and dry it at 40°C for 20 minutes. Remove the mold and dry it naturally to obtain a drug-loaded chitosan nerve regeneration tube (such as figure 2 c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com