Secondary growth preparation method of X type molecular sieve film on stainless steel metal net

A secondary growth, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, membrane technology, etc., can solve problems such as blocked pores, low molecular sieve membrane permeability, and molecular sieve membrane permeability decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Processing of metal mesh carrier:

[0048] Select 300-mesh stainless steel metal mesh (No. 540 Factory, Xinxiang, China) as the carrier, soak it in tap water, sonicate for 10 minutes under the condition of ultrasonic (ultrasonic power 100 watts, temperature 20 ℃), and finally rinse it with deionized water 3 times.

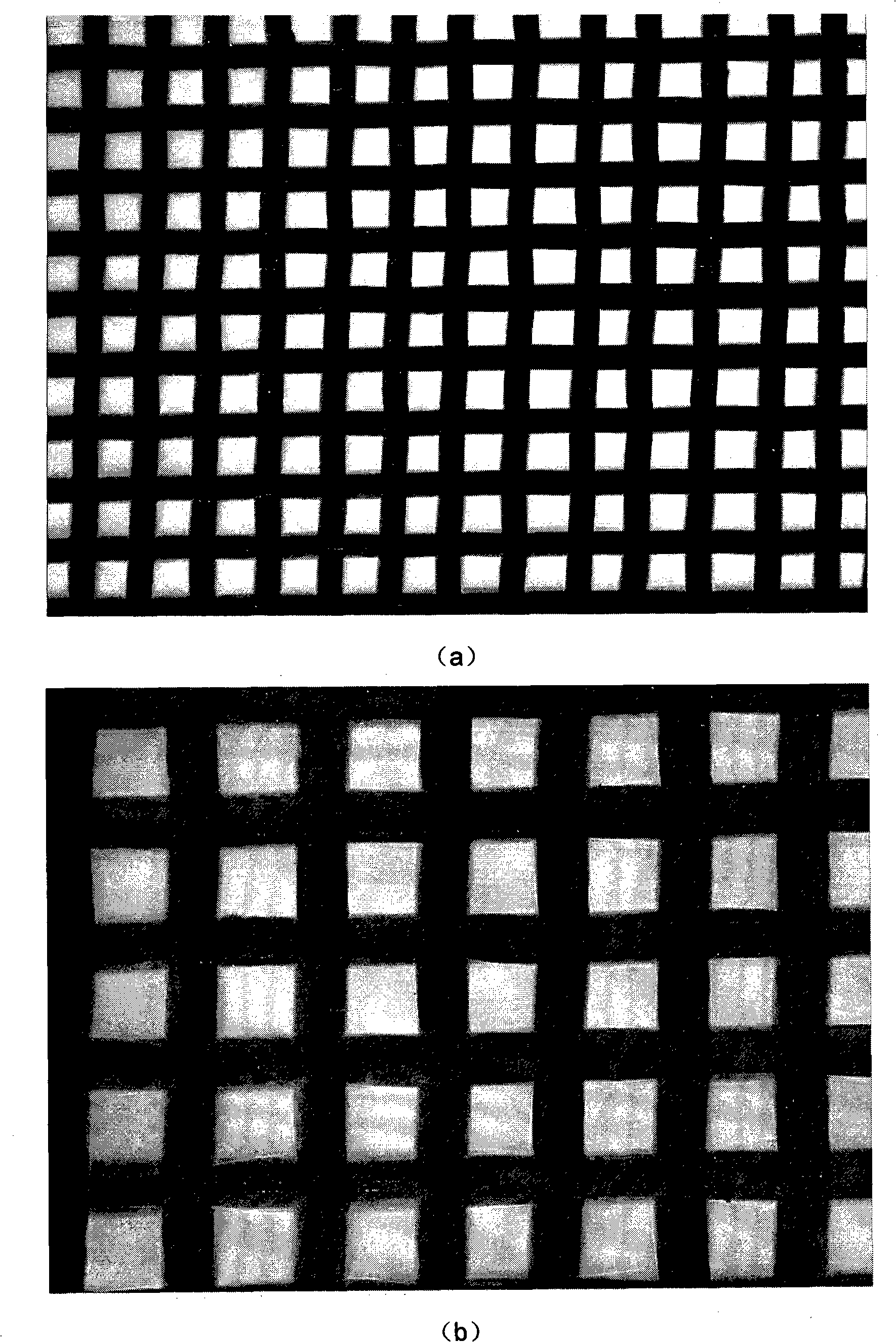

[0049] attached figure 1 It is an optical microscope photo of a 300-mesh stainless steel wire mesh.

[0050] Synthesis of seed crystals:

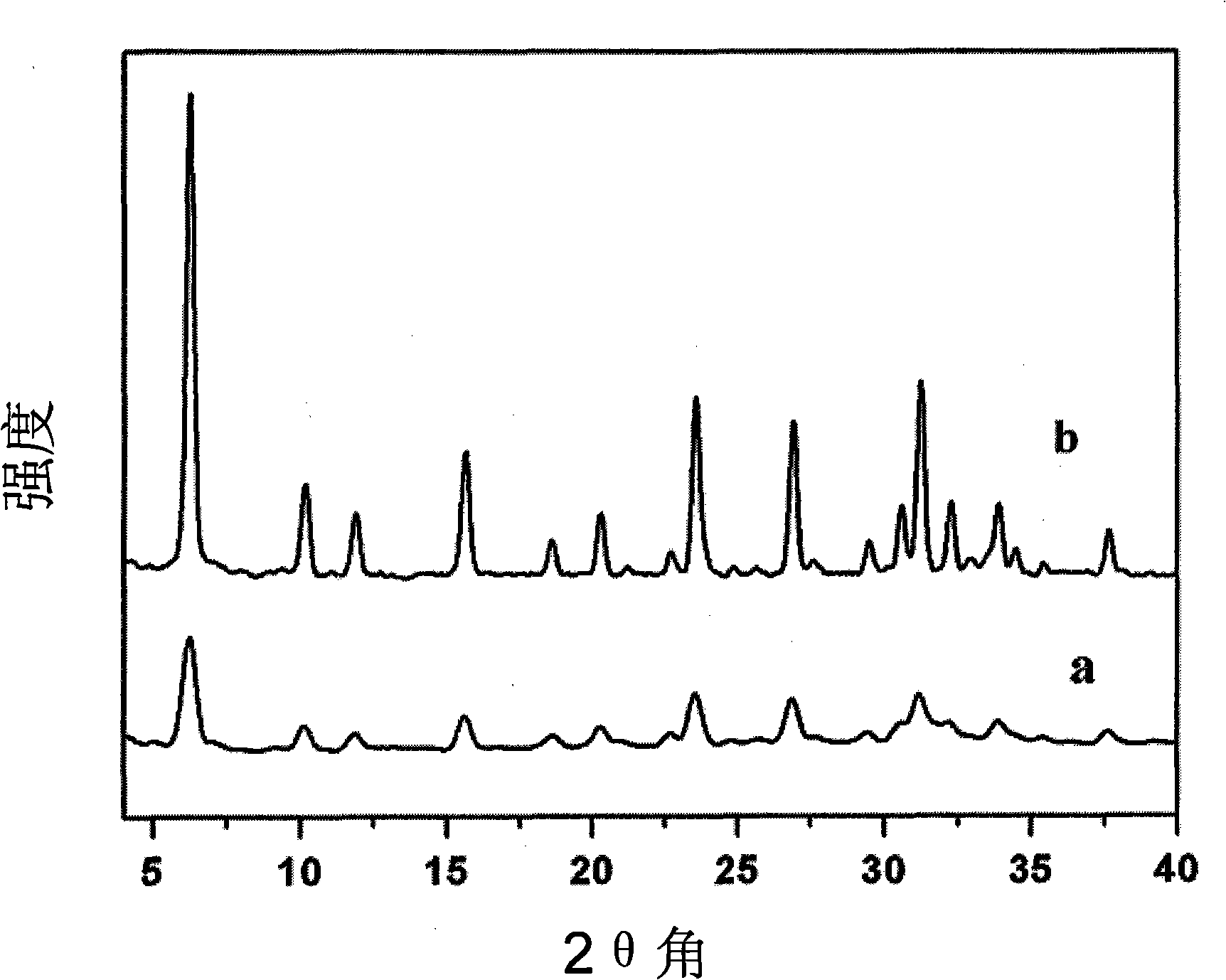

[0051] First, add 2.49 grams of sodium metaaluminate to 33.16 grams of water, add 2.99 grams of sodium hydroxide after dissolving, add 2.4 grams of white carbon black after dissolving, stir well and put it into a stainless steel reaction kettle lined with polytetrafluoroethylene , 2.5 days at 85°C. The product was suction-filtered and dried to obtain a seed crystal powder of X, the size of which was about 1 micron.

[0052] Preparation of the seed film:

[0053] Add 5 grams of X-type molecular sieve seed crystal powd...

Embodiment 2

[0061] The effects of different reaction times on the synthesis of X-type molecular sieve membranes were investigated.

[0062] The preparation of the seed crystal film was the same as in Example 1.

[0063] Membrane Synthesis:

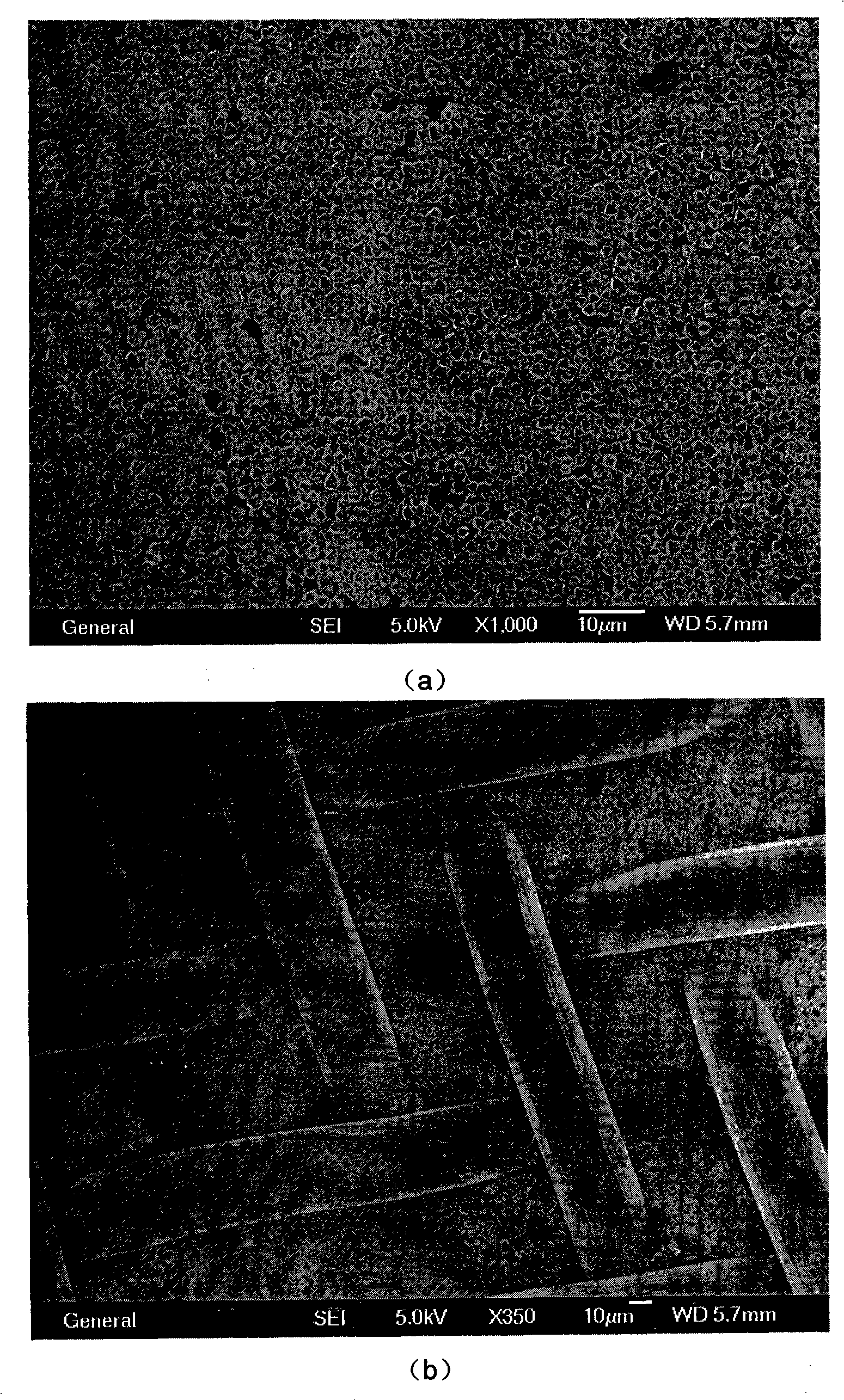

[0064] Different from Example 1, the reaction time was changed into 1, 2, 3, 4, 5, 6, 7 days, with Figure 6 SEM photographs of X-type zeolite membranes obtained for different reaction times. 1 to 7 are SEM photos of X-type molecular sieve membranes reacted for 1 to 7 days, respectively.

[0065] It can be seen from the figure that after 1 day of reaction, no obvious growth of the seed layer can be seen, but the molecular sieve membrane can be washed with deionized water without separation of the seed layer on the metal mesh from the metal mesh. On the second day of reaction, the growth of the seed layer was clearly seen, but the molecular sieve membrane was still discontinuous, with many voids and defects. On the third day of the reaction, the mo...

Embodiment 3

[0067] The effects of different solution concentrations on the synthesis of X-type molecular sieve membranes were investigated.

[0068] The preparation of the seed crystal film was the same as in Example 1.

[0069] Membrane Synthesis:

[0070] Different from Example 1, in the solution ratio (molar ratio) 6.4mol NaOH: 4mol SiO 2 : 2mol NaAlO 2 : x mol H 2 In O, the values of x are 190, 356, 600, 1187, 1662 and 2375 respectively. attached Figure 7SEM photographs of X-type molecular sieve membranes obtained for different solution concentrations. Among them, 1 to 6 are the SEM photos corresponding to the values of x of 190, 356, 600, 1187, 1662 and 2375, respectively.

[0071] It can be seen from the figure that too high or too low solution concentration is not conducive to the growth of X-type zeolite molecular sieve membrane. When the concentration is too high, the solution is prone to homogeneous nucleation, and it is easy to crystallize and grow X-type zeolite mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com