Method of manufacturing medicinal cold-forming composite aluminum foil

A composite aluminum foil, cold forming technology, applied in chemical instruments and methods, flexible covering, lamination, etc., to achieve the effect of no peeling off, no solvent odor, and safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

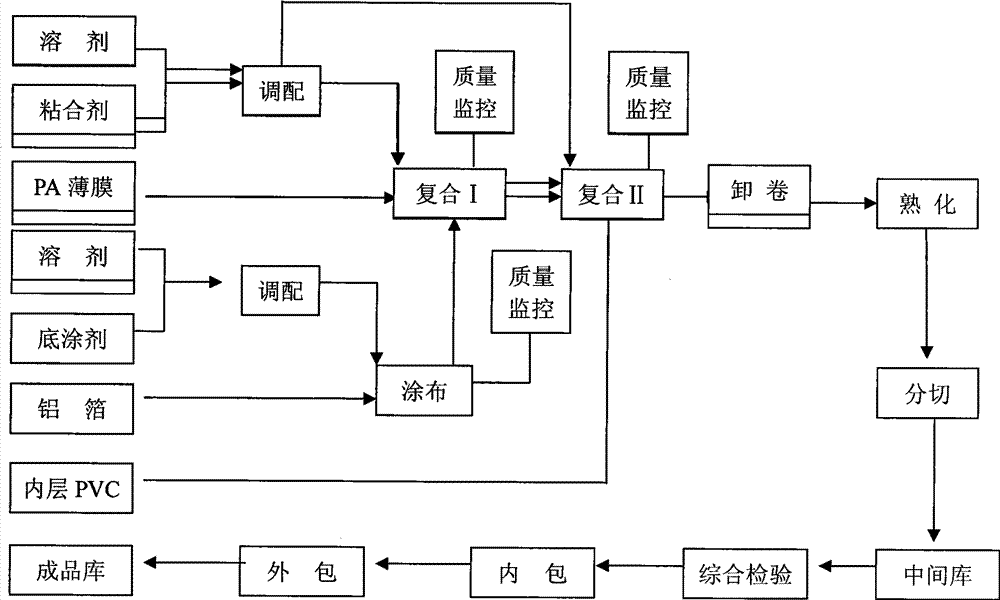

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described with reference to specific embodiments.

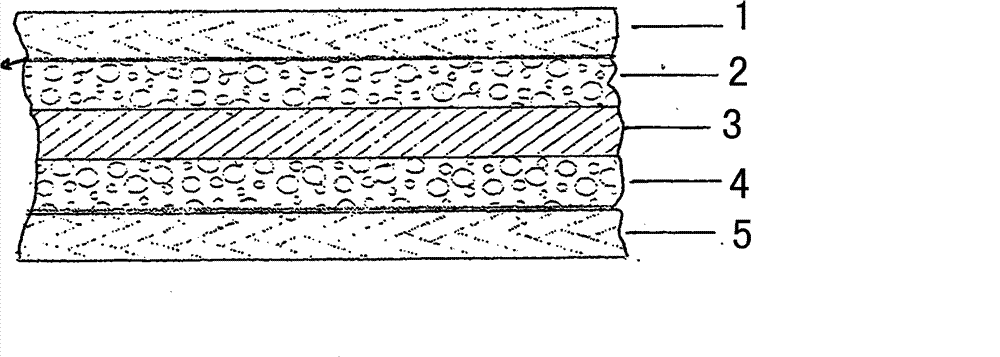

[0020] The medicinal cold-formed composite aluminum foil prepared by the invention is used for the packaging of solids (tablets, capsules, granules, powders, etc.). It is currently a higher-end packaging material that can increase the shelf life of drugs to 3 -5 years. See the specific structure figure 2 ,

[0021] The thickness of the nylon PA layer is 25 μm, and the thickness of the aluminum foil is 45-50 μm. The width of the medicinal cold-formed composite aluminum foil is less than 1000mm, and it can also be determined according to the needs of the user. The outer diameter of the roll is less than 40mm, or it can be determined according to the needs of the user.

[0022] The allowable error of the medicinal cold-formed composite aluminum foil is: the width d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com