Immobilization method for anaerobic fermentation bacterial active sludge

A technology of activated sludge and anaerobic fermentation, applied in fermentation, biological sludge treatment, immobilization on or in inorganic carriers, etc. Fermentation and COD removal characteristics, low production cost, simple and easy-to-use preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

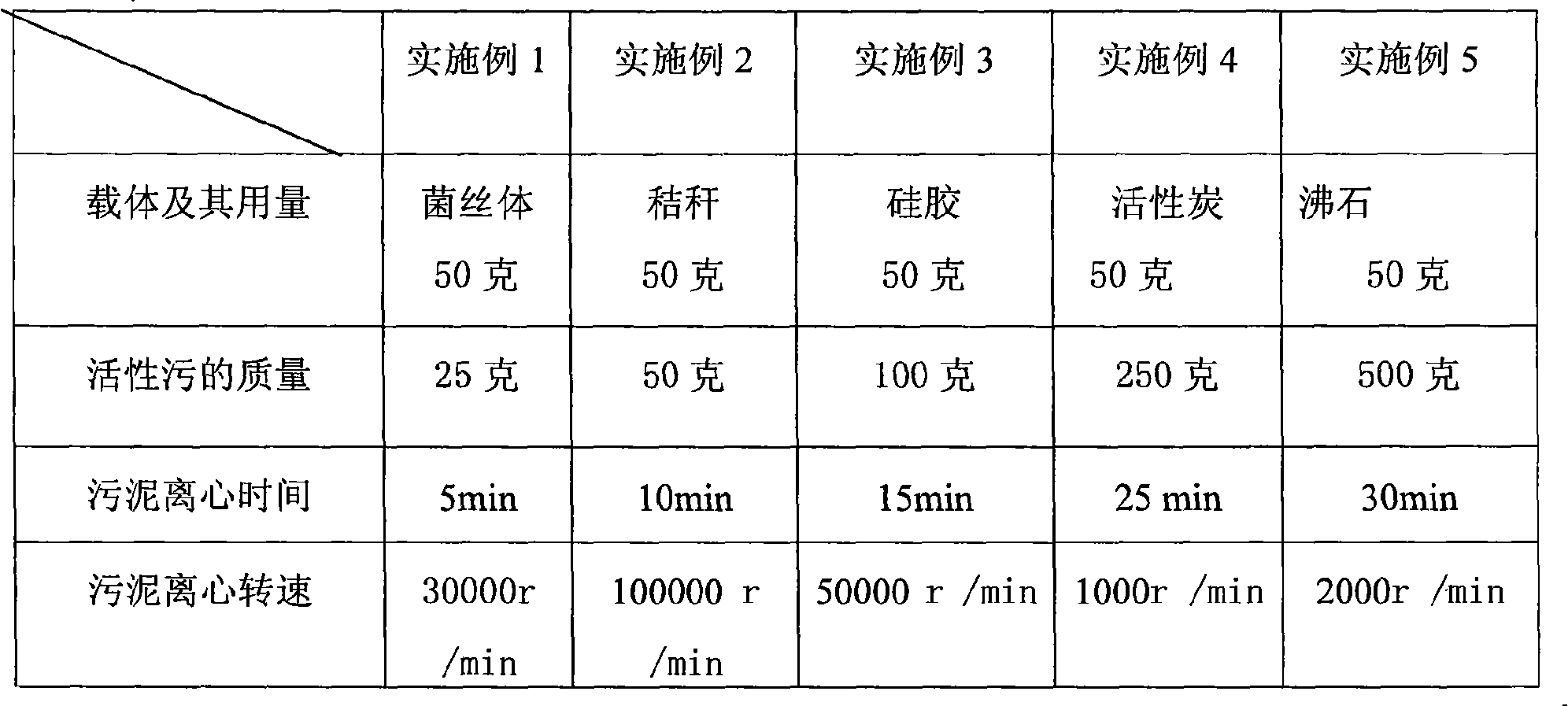

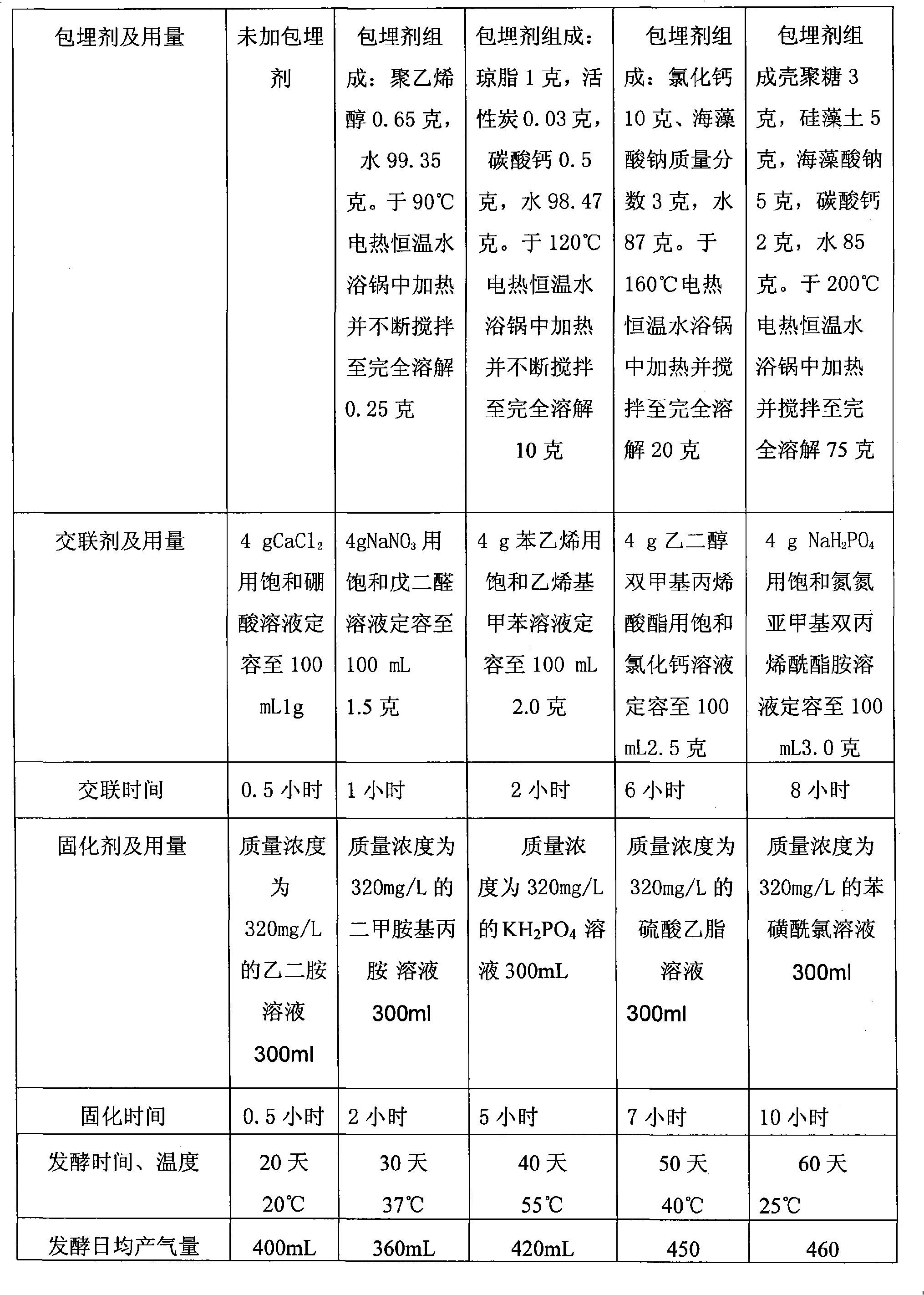

Embodiment 1

[0024] Centrifuge the activated sludge in a centrifuge for 5 minutes at a speed of 30,000 r / min to obtain concentrated activated sludge.

[0025] Get 25 grams of the above concentrated activated sludge, then add 50 grams of solid carrier mycelium, the ratio of solid carrier to concentrated activated sludge mass is 2:1;

[0026] After the solid carrier mycelium is fully stirred and mixed with the concentrated activated sludge, the solid carrier that has absorbed the activated sludge is placed in a cross-linking agent with calcium chloride, and dried to obtain immobilized particles;

[0027] The prepared immobilized particles were cross-linked for 0.5 h, and then placed in a curing agent solution of ethylenediamine for 0.5 h to obtain immobilized activated sludge 1 .

[0028] Take 25 grams of starch-based catering organic waste, the water content is 65%, add 100g of immobilized activated sludge 1, add water to 800ml, add water to 800ml, control the temperature at 20 degrees Cels...

Embodiment 2

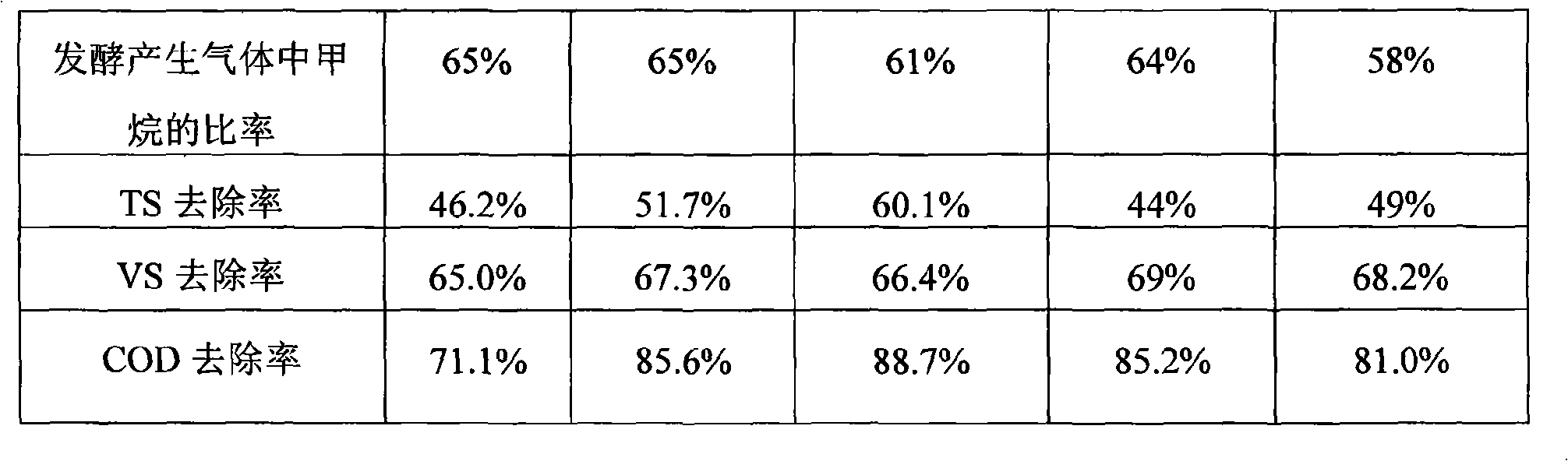

[0031] Example 2: Get 25 grams of cellulose-based catering organic waste, with a water content of 70%, add 100 g of immobilized activated sludge 2, add water to 800 ml, control the temperature at 37 degrees Celsius, and the fermentation cycle is 30 days. The average daily gas production is 360ml, the methane content is about 65%, the TS removal rate is 51.7%, the VS removal rate is 67.3%, and the COD removal rate is 85.6%.

Embodiment 3

[0032] Embodiment 3: Utilize immobilized activated sludge 3 to carry out anaerobic fermentation. Take 25 grams of oil-based catering organic waste, with a water content of 80%, add 100 g of immobilized activated sludge 3, add water to 800 ml, control the temperature at 55 degrees Celsius, and the fermentation period is 40 days. The average daily gas production during the fermentation process is 420ml, the methane content is about 61%, the TS removal rate is 60.1%, the VS removal rate is 66.4%, and the COD removal rate is 88.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com