Hydrodynamic force motor type hard rock deep borehole drilling device

A deep hole drilling and hydrodynamic technology, which is applied in drilling equipment, earthwork drilling, driving device for drilling in wellbore, etc., to achieve the effect of improving drilling efficiency, improving operation efficiency and high straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

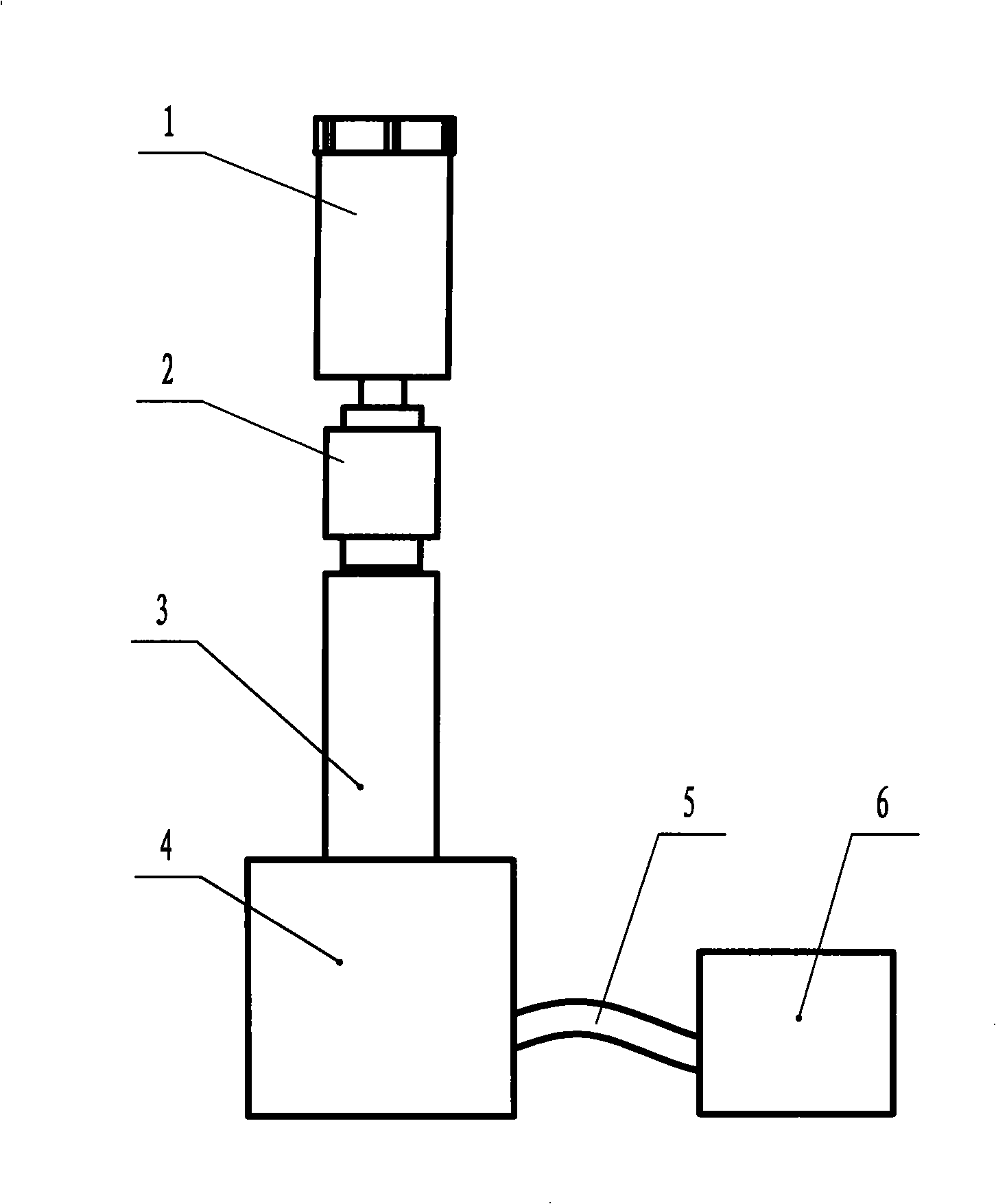

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] It can be seen from the accompanying drawings that the main components of the equipment include a diamond drill bit 1, a micro hydrodynamic motor 2, a drill pipe 3, a propulsion device 4, a pressurized water pump 6, the tail of the diamond drill bit 1 and the power output end of the micro hydrodynamic motor 2 Connection, the power input end of the micro hydrodynamic motor 2 is connected to the drill pipe 3, and the drill pipe 3 is connected to the propulsion device 4; the drill pipe 3 is a hollow tubular structure, and its front end communicates with the water inlet of the micro hydrodynamic motor 2, and the It communicates with a pressurized water pump 6 through a high-pressure water pipe 5 .

[0017] The power output end of the hydrodynamic motor 2 is an output shaft, and a water hole leading from the hydrodynamic motor 2 to the inside of the drill bit 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com