Brake control unit for locomotive electro-pneumatic brake

An electro-pneumatic braking and braking control technology, which is applied to vehicle control route devices, railway car body components, railway signals and safety, etc. Fault information and other issues, to achieve the effect of improving handling performance and safety, good stability and anti-interference, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

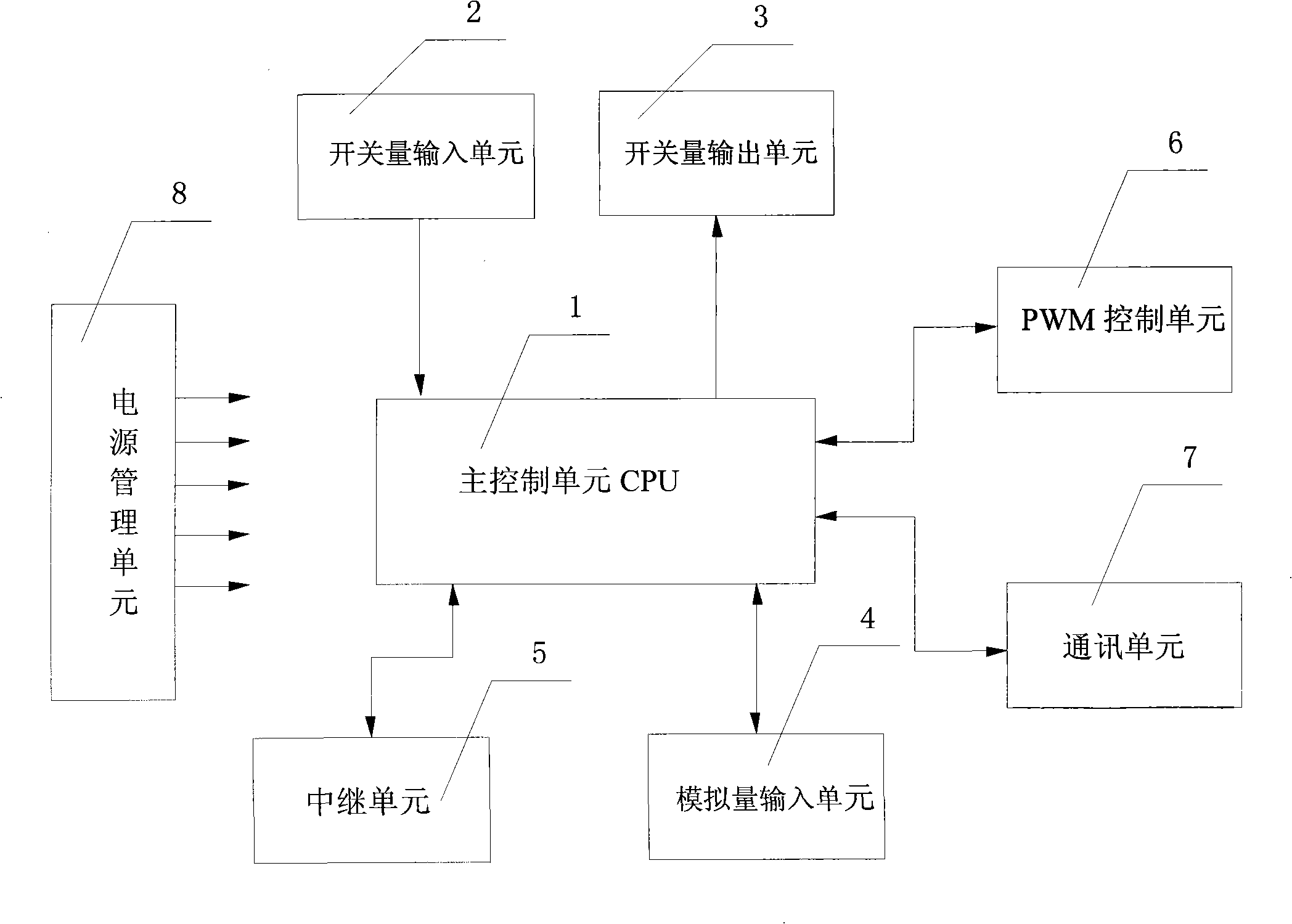

[0061] Such as figure 1 As shown, a brake control unit for locomotive electro-pneumatic brakes of the present invention includes a main control unit 1, a switch input unit 2, a switch output unit 3, an analog input unit 4, and a relay unit 5. The PWM drive unit 6, the communication unit 7 and the power management unit 8 for supplying power to the above-mentioned components, the switching value input unit 2 for inputting the digital control signal is connected to the input terminal of the main control unit 1 for outputting the digital control signal The switch value output unit 3 is connected to the output end of the main control unit 1, the main control unit 1 controls the pressure of the balance air cylinder 9 and the brake air cylinder 10 of the electric control motor through the PWM drive unit 6, and the main control unit 1 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com