Flaking molding method and apparatus for p-dihydroxy benzene

A technology of hydroquinone flaking and quinone flaking, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as cumbersome operating procedures, high energy consumption, and large environmental pollution. Achieve the effects of simple operation procedures, low environmental pollution and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

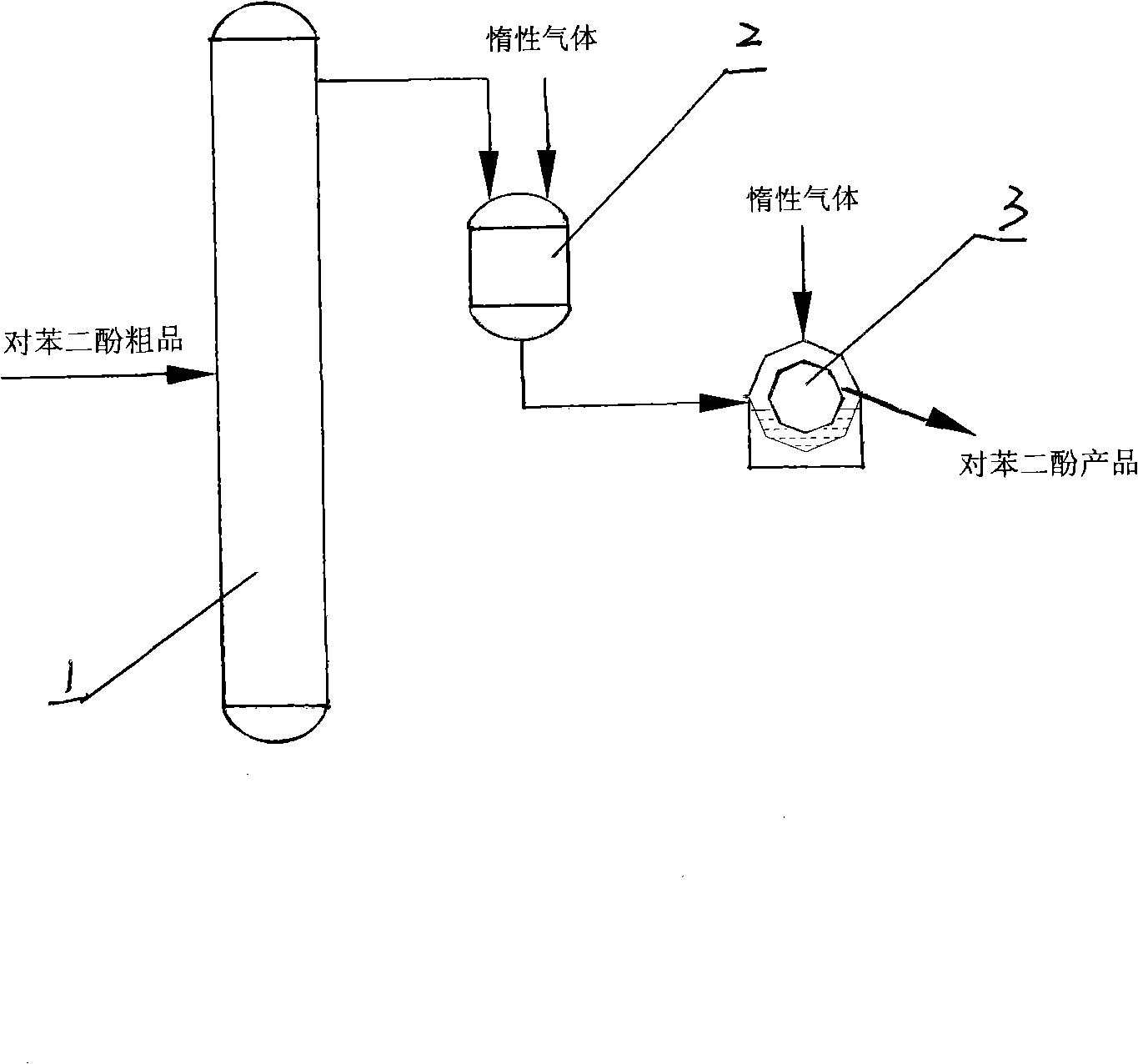

[0020] Example 1. refer to figure 1 . A hydroquinone knot sheet forming method, the steps are as follows:

[0021] (1) the hydroquinone crude product that contains impurity produced in previous process is put in the hydroquinone rectifying tower 1, separates by rectification, with respect to the low boiler of hydroquinone and the high boiler respectively Discharge from the top and the bottom of the tower to obtain pure hydroquinone;

[0022] (2) The pure hydroquinone is extracted intermittently or continuously from the upper part of the hydroquinone rectification tower 1 to the pure hydroquinone liquid receiving tank 2 for collection and storage, and the receiving tank 2 is heated by a heat-conducting medium at the same time to keep The hydroquinone in the tank is in liquid state, and the tank is filled with inert gas to prevent the oxidation of hydroquinone;

[0023] (3) The liquid hydroquinone is sent into the flaking machine 3 from the receiving tank 2, and at the same ...

Embodiment 2

[0024] Example 2. In the step (1) of the method for forming hydroquinone flakes described in Example 1, the operating pressure of the hydroquinone rectifying tower 1 during rectification and separation is 1 kPa.

Embodiment 3

[0025] Example 3. In the step (1) of the method for forming hydroquinone flakes described in Example 1, the operating pressure of the hydroquinone rectifying tower 1 during rectification and separation is 50 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com