Improved simulated moving bed separation method

A technology of simulating moving bed and separation method, applied in the direction of moving adsorbent separation, ion exchange, ion exchange regeneration, etc., can solve the problems of increasing the amount of eluent, reducing the injection volume Feed, and increasing the system pressure. The effect of high injection fluid flow and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

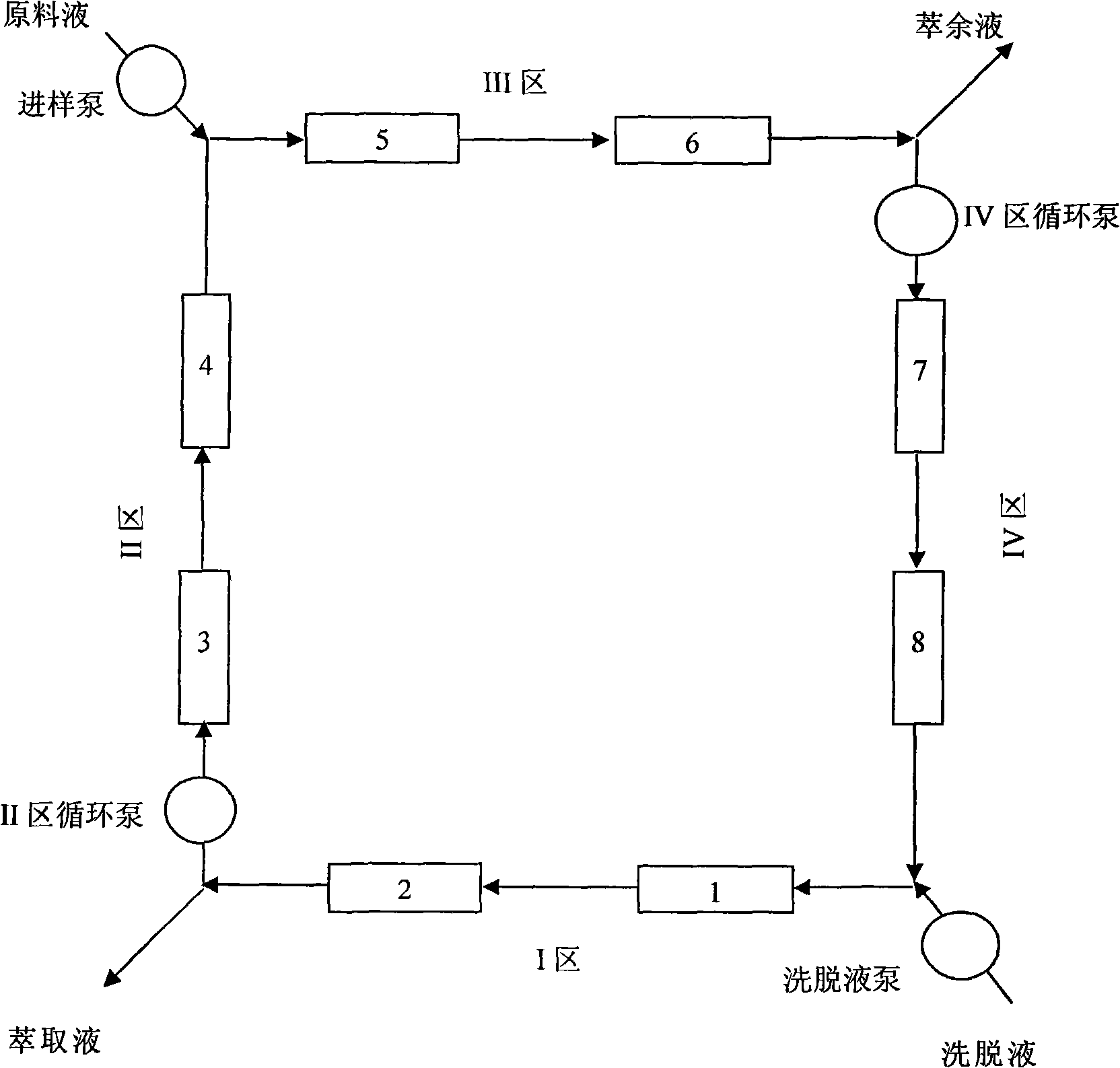

[0050] Example 1 Conventional Simulated Moving Bed Separation

[0051] Use methanol / water (volume ratio is 65 / 35) solution preparation concentration to be the capsaicin total alkaloid solution of 40mg / mL, it is pumped into separation system with 1.4mL / min flow rate from the sample liquid inlet between II area and III area , and the methanol / water (volume ratio 60 / 40) solution is used as the eluent, and flows into the I zone together with the IV zone effluent from the eluent inlet between the I zone and the IV zone at a flow rate of 2 mL / min. The flow rates in zones I to IV were set at 12, 4.5, 5.9, and 4 mL / min, respectively. Switching time is set to 10min.

[0052] The extract and raffinate were detected by high performance liquid chromatography, and the results showed that the strongly adsorbed components and weakly adsorbed components had been completely separated.

Embodiment 2

[0053] Example 2 Conventional Simulated Moving Bed Separation

[0054] With methanol / water (volume ratio 95 / 5) solution preparation concentration is the capsaicin total alkali solution of 40mg / mL, it is pumped into separation system with 0.02mL / min flow rate from the sample liquid inlet between II district and III district, And the methanol solution flows into the I zone together with the effluent from the IV zone from the eluent inlet between the I zone and the IV zone at a flow rate of 0.19mL / min. The flow rates in areas I to IV were set at 0.9, 0.73, 0.75, and 0.72 mL / min, respectively. Switching time is set to 10min.

[0055] The extract and raffinate were detected by high performance liquid chromatography, and the results showed that the strongly adsorbed components and weakly adsorbed components had been completely separated.

Embodiment 3

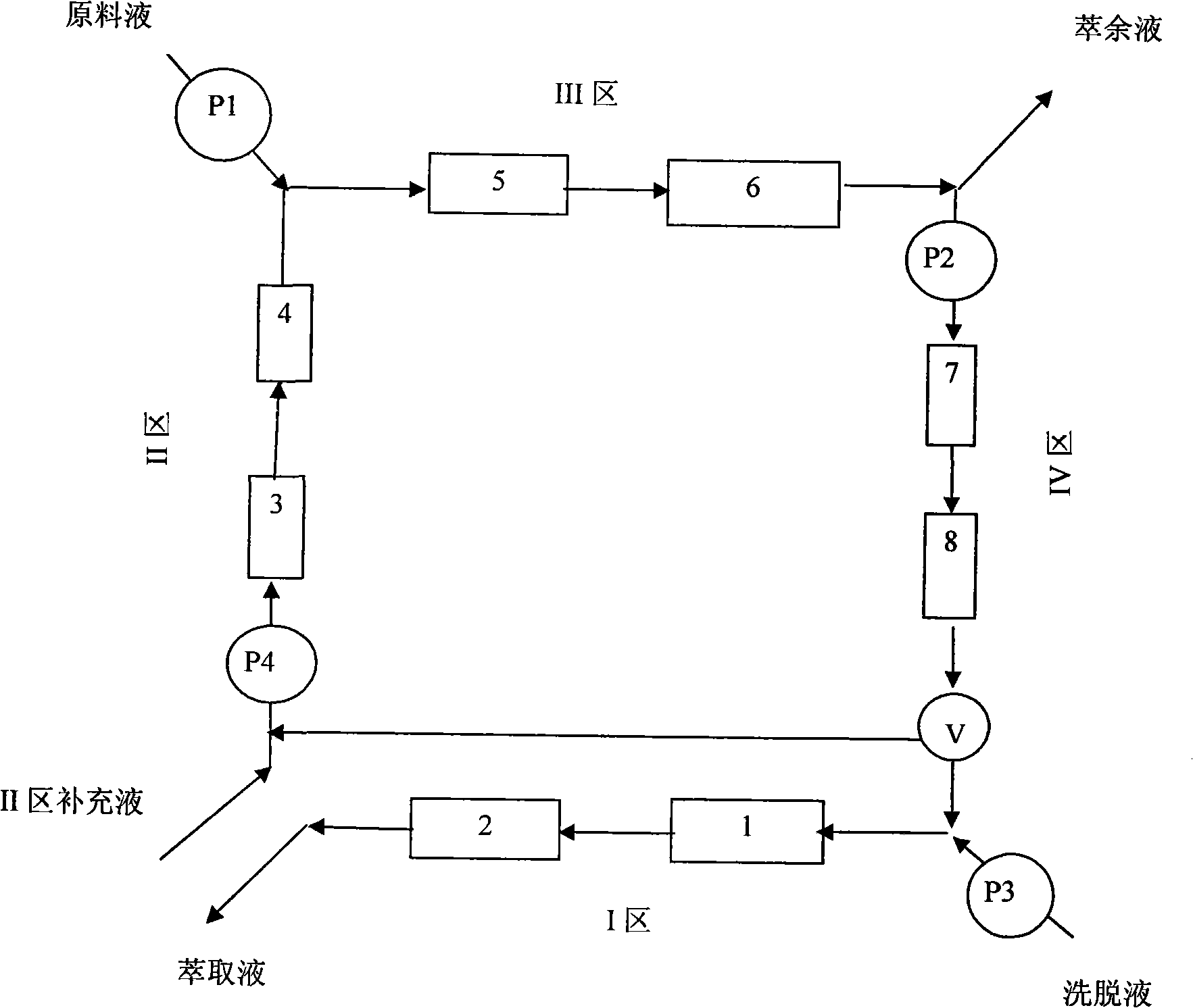

[0056] Embodiment 3 improved simulated moving bed separation

[0057] Use methanol / water (volume ratio is 65 / 35) solution to prepare capsaicin compound with a concentration of 40mg / mL, and pump it into the separation system with a flow rate of 1.4mL / min from the inlet of the sample solution between the II area and the III area , and pump pure methanol into the separation system at a flow rate of 0.8 mL / min from the eluent inlet between Zone I and Zone IV. In each switching cycle, when the volume of the effluent from zone IV is less than 1 times the column volume, the effluent from zone IV is mixed with pure methanol and flows into zone I; The methanol / water (volume ratio 65 / 35) solution is pumped into Zone II together. The flow rates in areas I to IV were set at 0.9, 4.5, 5.9, and 3.9 mL / min, respectively. Switching time is set to 10min.

[0058] The extract and raffinate were detected by high performance liquid chromatography, and the results showed that the strongly adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com