Turbine type gas starting equipment of diesel engine

A diesel engine and gas starting technology, which is applied to the starting of the engine, the starting device with fluid drive, engine components, etc., can solve the problems of potential safety hazards, low efficiency, and easy water ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

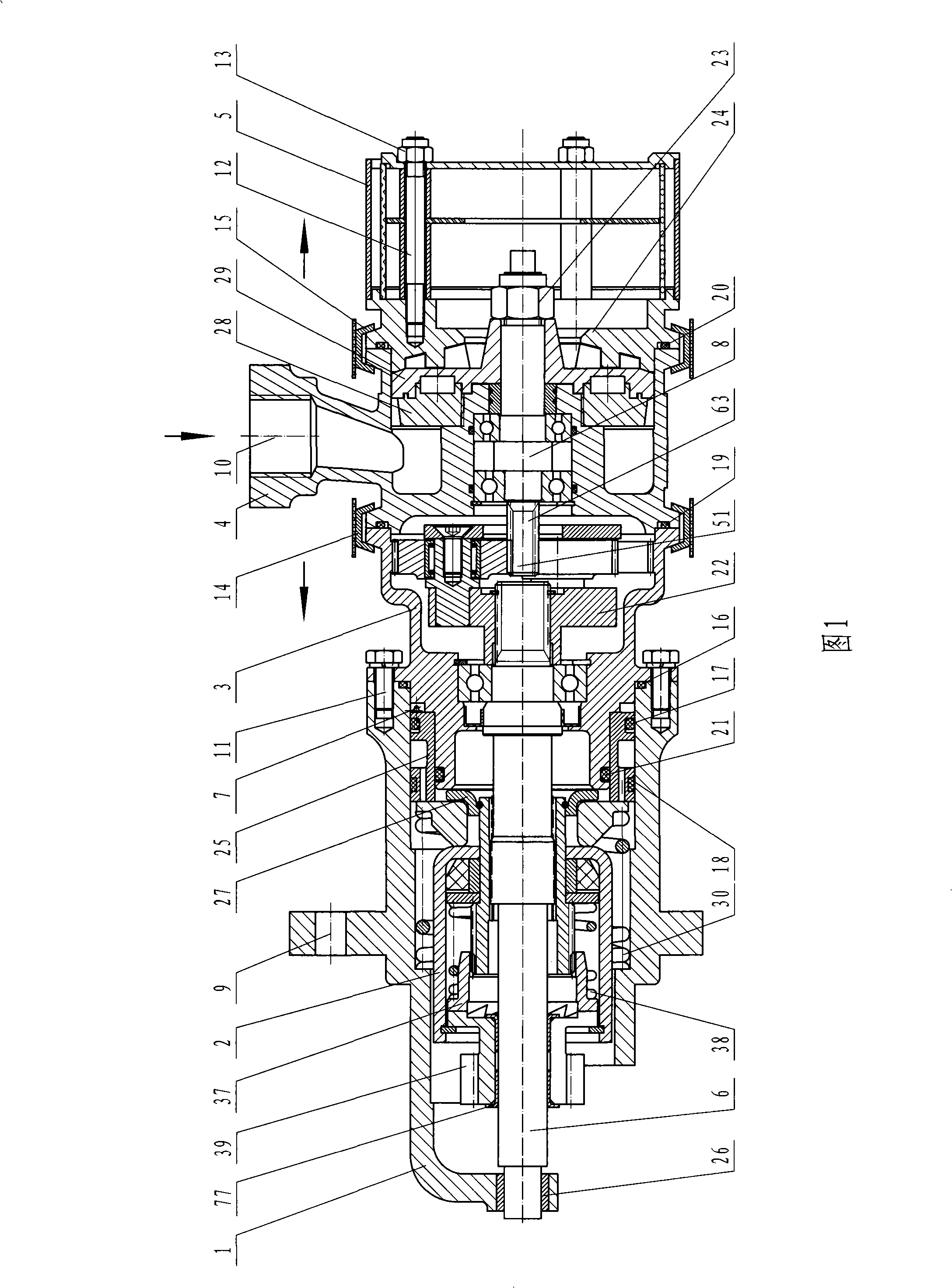

[0036] The present invention will be further described below in conjunction with accompanying drawing:

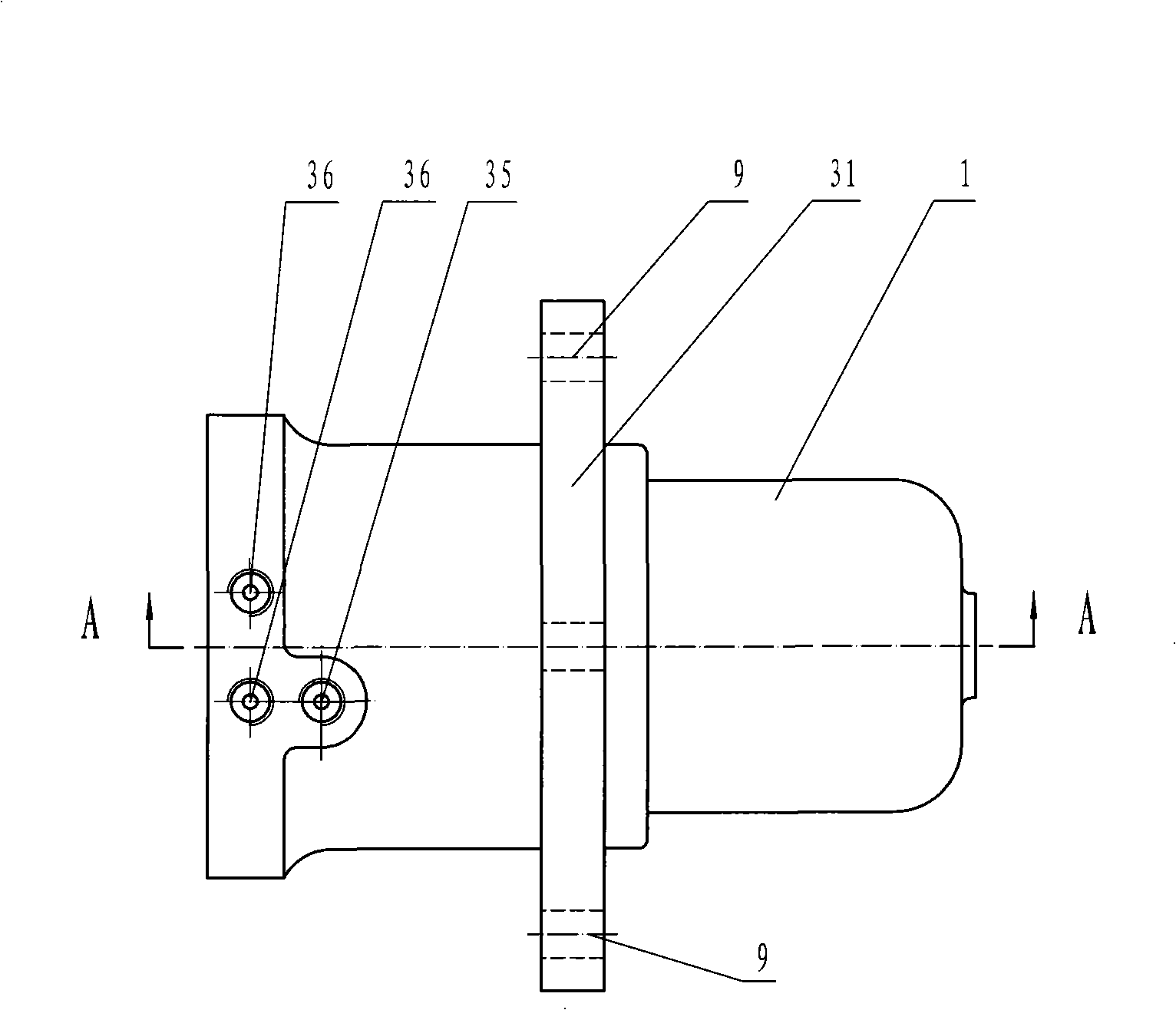

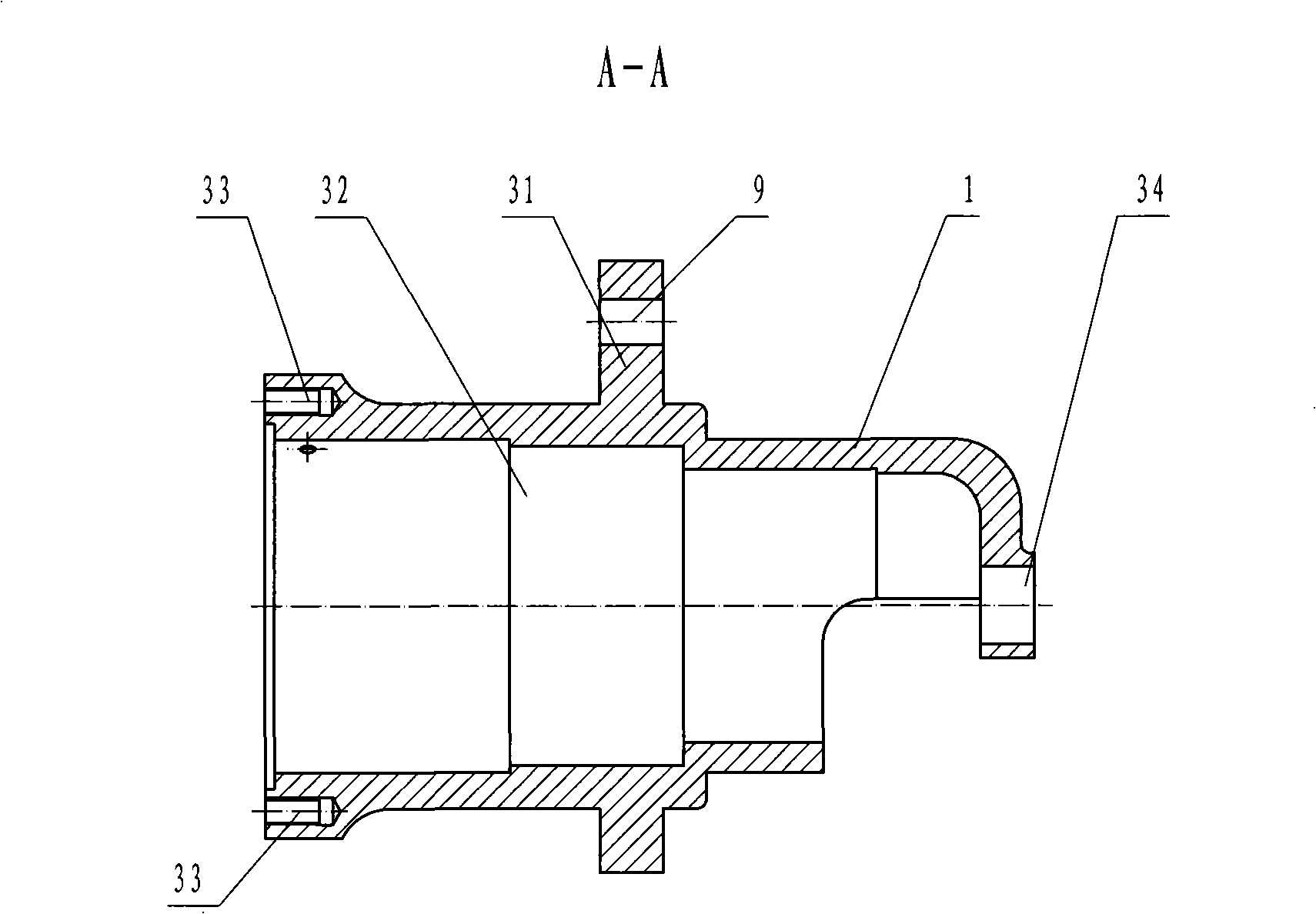

[0037] As shown in Figure 1, it is the overall structure diagram, which is mainly composed of a turbine drive mechanism 4, a muffler 5, a planetary reducer 3, a one-way device 2, and a connecting housing 1. The air gas generated by the air compressor has a pressure value of 700KPa and is divided into Two air streams, one enters the slider cavity 7 from the air hole 36, and the other enters the turbine drive mechanism 4 from the air passage 10, and divides the flow through the helical teeth on the inner impeller 28, the turbine rotor 29, and the outer impeller 24, so that the turbine rotor 29 is in the air. The turbine shaft 8 rotates and drives the sun gear 51 of the planetary reducer 3 to rotate. The sun gear 51 drives the planetary gear 44 to rotate and decelerate. The deceleration speed ratio is 11.4:1. After deceleration, the power is transmitted to the drive shaft 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com