Apparatus for heat treatment of wafer

A heat treatment device and wafer technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve problems such as yield drop, long time, damage, etc., to reduce air residue, increase exhaust volume, and improve exhaust The effect of gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

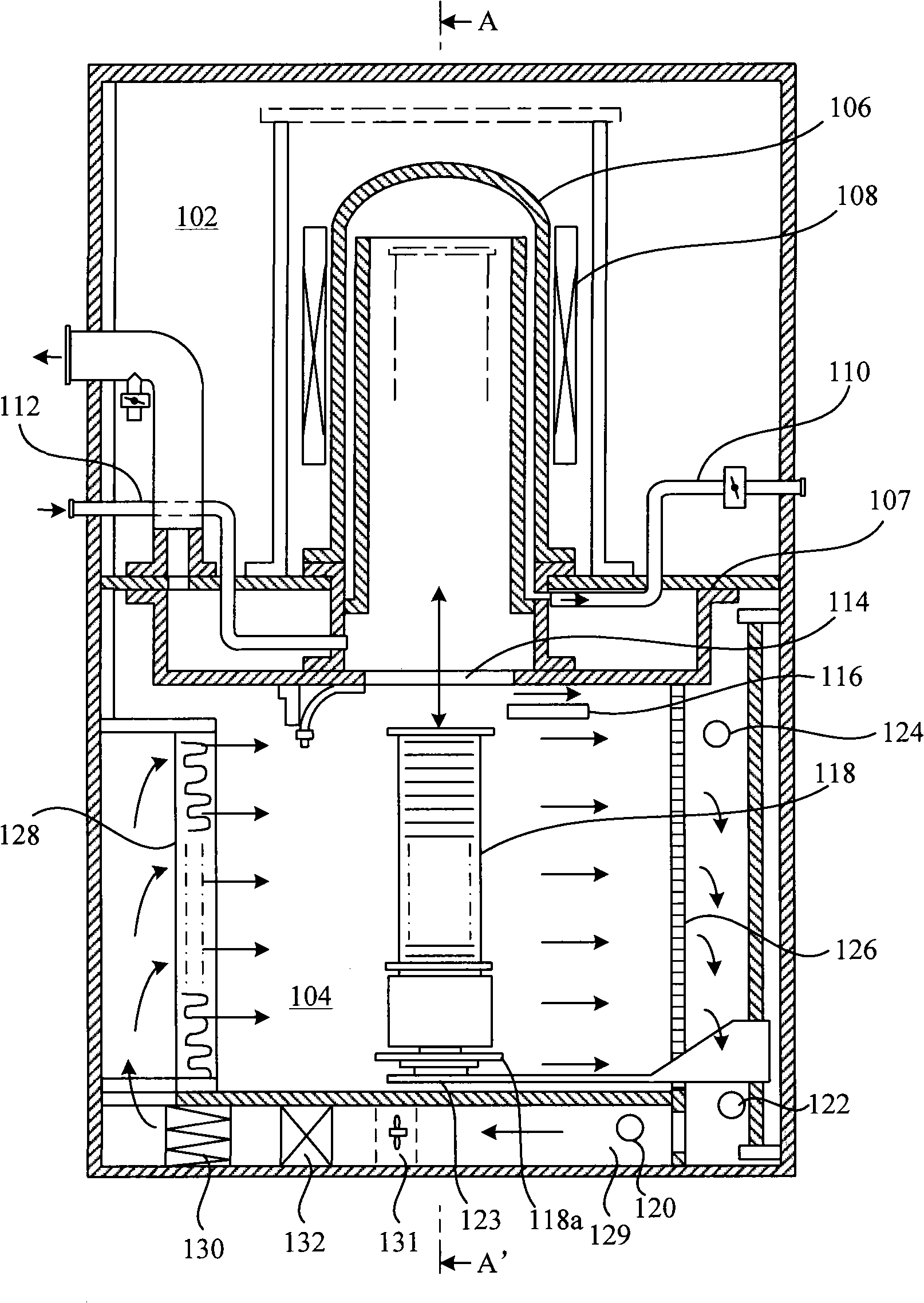

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

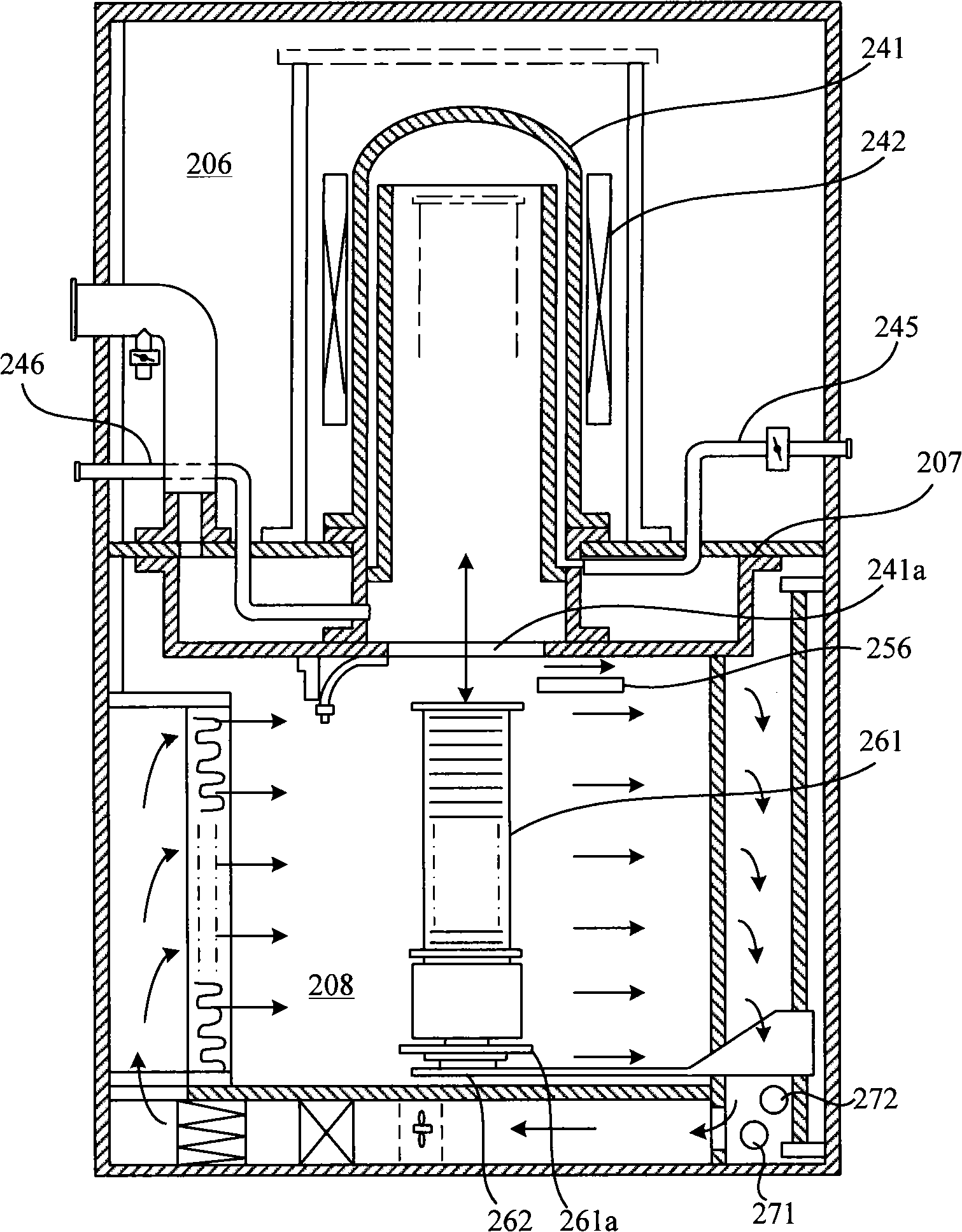

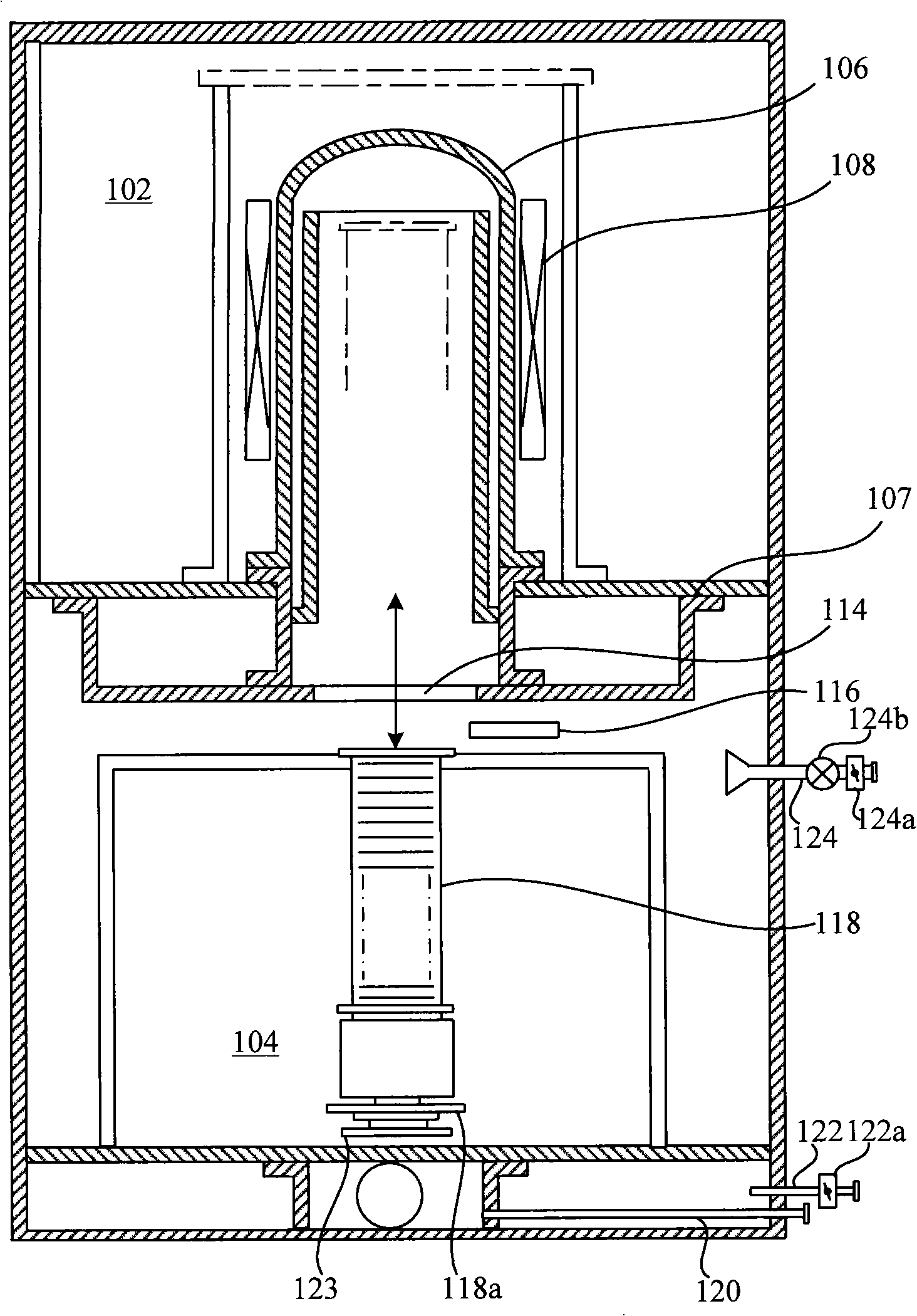

[0033] figure 2 It is a schematic cross-sectional view of the first embodiment of the wafer heat treatment device of the present invention, image 3 for figure 2 Schematic cross-section along AA'. Such as figure 2 As shown, the loading chamber 104 is located below the heat treatment process chamber 102 , and the spacer 107 is hermetically sealed between the loading chamber 104 and the heat treatment process chamber 102 .

[0034] There is a vertically placed liner 106 in the heat treatment process chamber 102. The liner 106 is an inverted "U" shape with a closed upper end and a lower end connected to the isolation device 107. The liner 106 is made of quartz. Multiple sets of heaters 108 are distributed on the sidewall of the liner 106; the heaters 108 may be resistance wires. The heater 108 heat-treats the semiconductor wafer in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com