Multi-functional special oiling device for deep-sea hydraulic system

A technology of hydraulic system and oil injection device, which is applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc. Reduce and other problems, to avoid the decline of oil purity, reduce air residue, and avoid secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

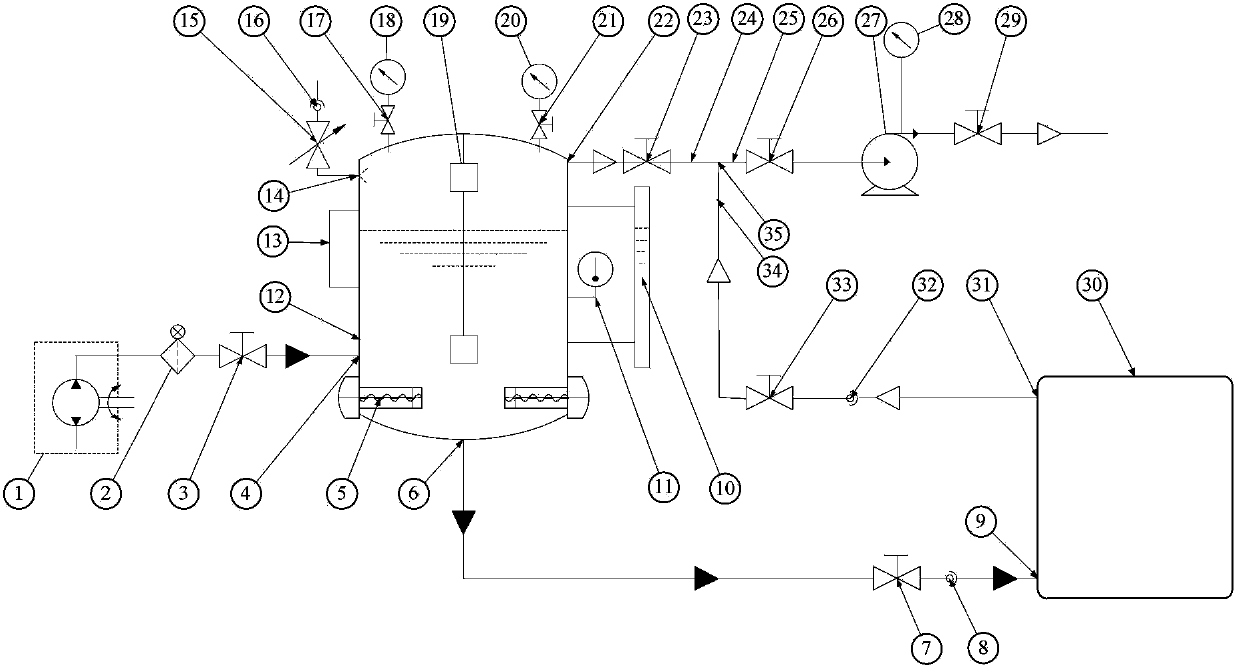

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the present invention includes an essential oil filter 2, a first low-pressure ball valve 3, an electric heater 5, a second low-pressure ball valve 7, a first quick connector 8, a liquid level gauge 10, an electric contact thermometer 11, a vacuum tank 12, Power distribution box 13, throttle valve 15, second quick connector 16, pressure gauge switch 17, electric contact pressure gauge 18, multi-point liquid level control relay 19, electric contact vacuum gauge 20, vacuum gauge switch 21, third low-pressure ball valve 23. The fourth low pressure ball valve 26, the rotary vane vacuum pump 27, the pressure gauge 28, the fifth low pressure ball valve 29, the hydraulic equipment to be filled 30, the third quick connector 32, the sixth low pressure ball valve 33, and the three-way connector 35. An electric heater 5, a multi-point liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com