Method for determining groove etch time and method for preparing isolation of shallow channel

A technology of etching time and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult trench etching time and complicated process, and achieve simplification of research and development process, cost reduction, The effect of saving R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

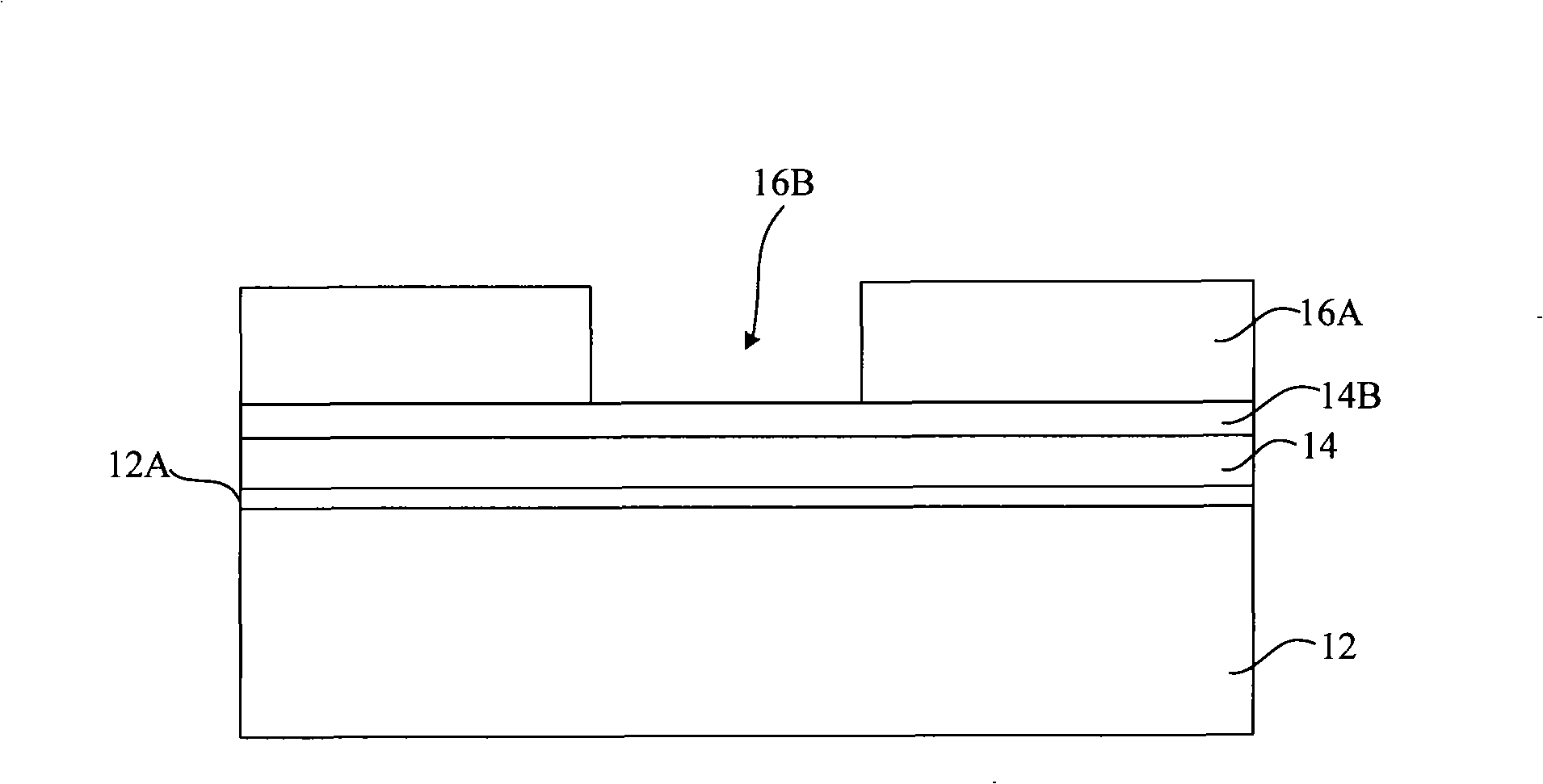

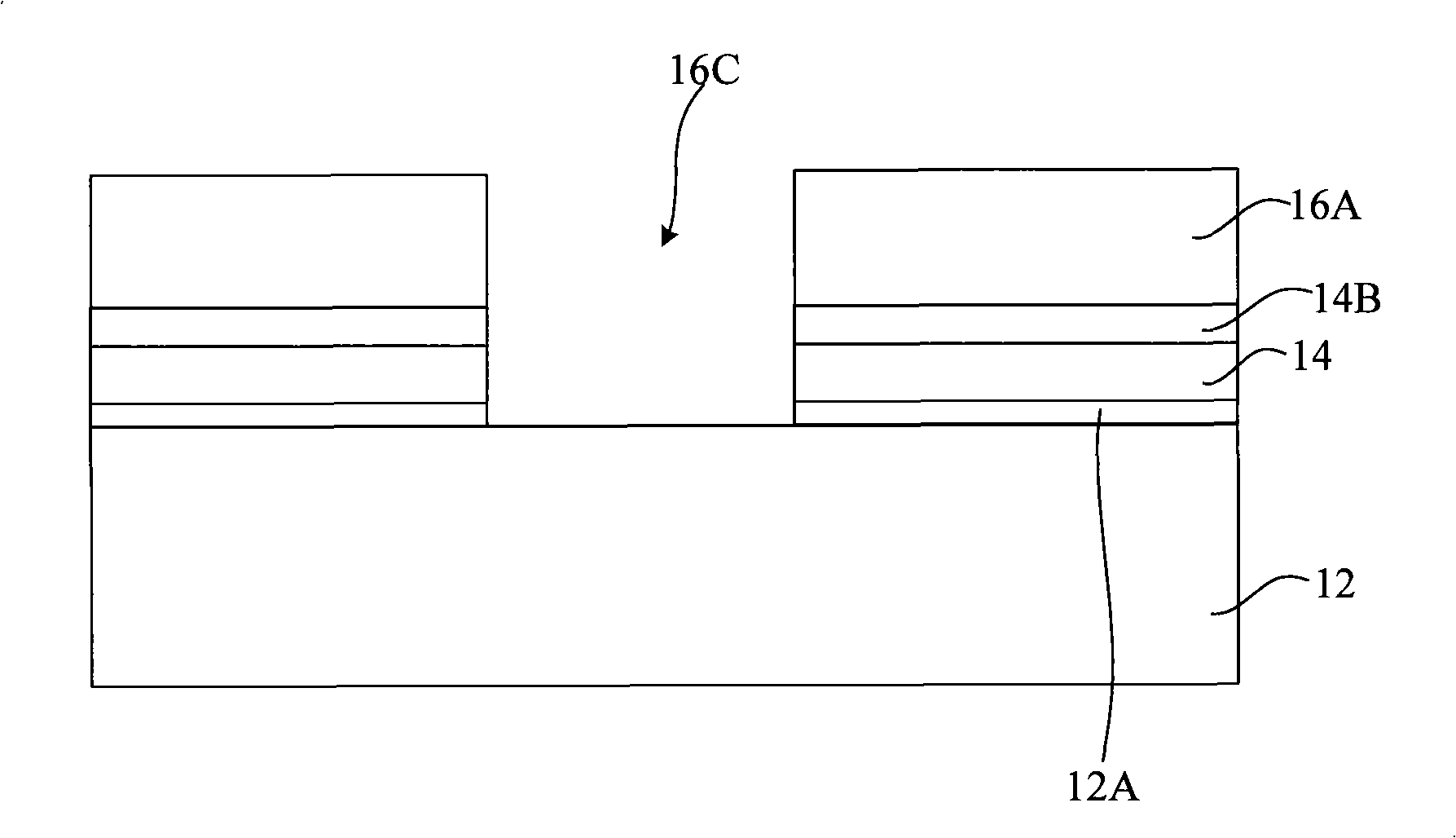

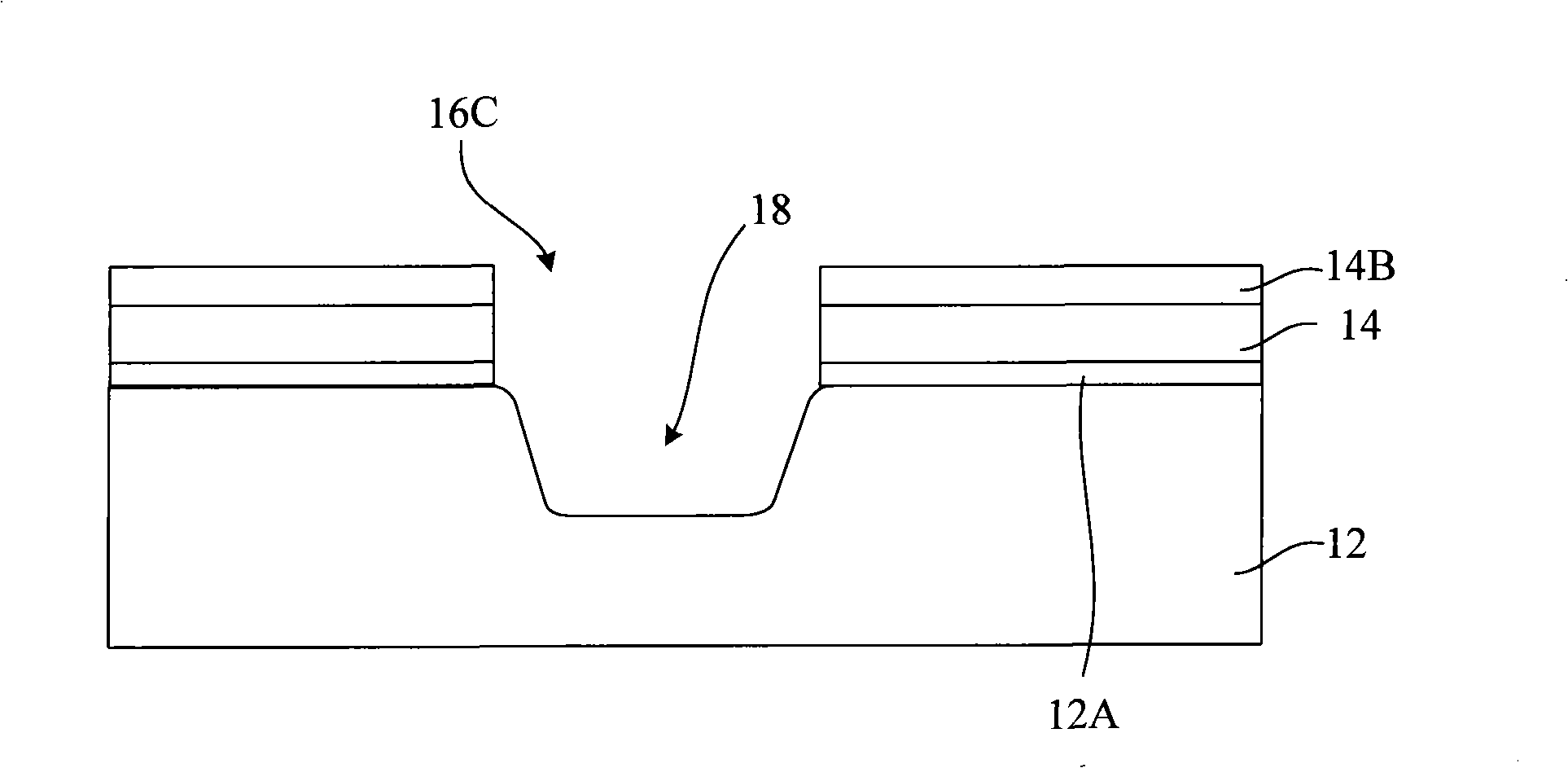

[0051] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0052] In the semiconductor manufacturing process, it is often necessary to make trenches in the semiconductor substrate, for example, when forming an active region, it is necessary to form an isolation trench in the semiconductor substrate; when etching the trench in the semiconductor substrate, the etching time It is not only related to the depth of the trench, but also related to the density of the trench. The etching time of trenches with different densities is different; and with the development of semiconductor manufacturing processes, the integration level is getting higher and higher. The density of grooves in different products is not the same, and the etching time of grooves needs to be determined through more experiments and tests, which brings great difficulties to the determination of groove etching conditions; for For the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com