Composite heat insulation heat insulating concrete structural system wall door, window hole mould and construction method

A technology of heat-insulating concrete and composite heat-preservation, which is applied in the field of hole moulds to achieve the effects of precise installation, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

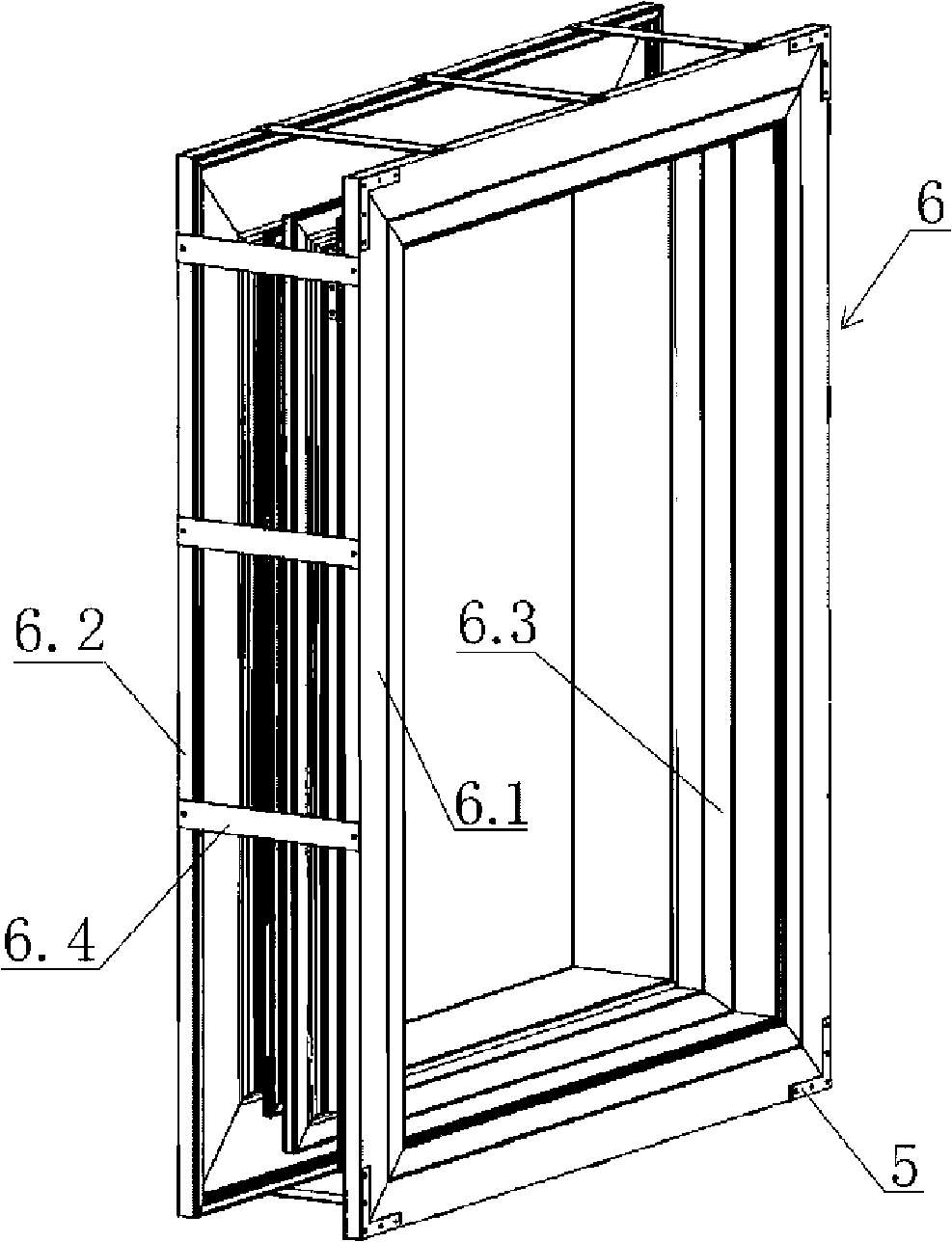

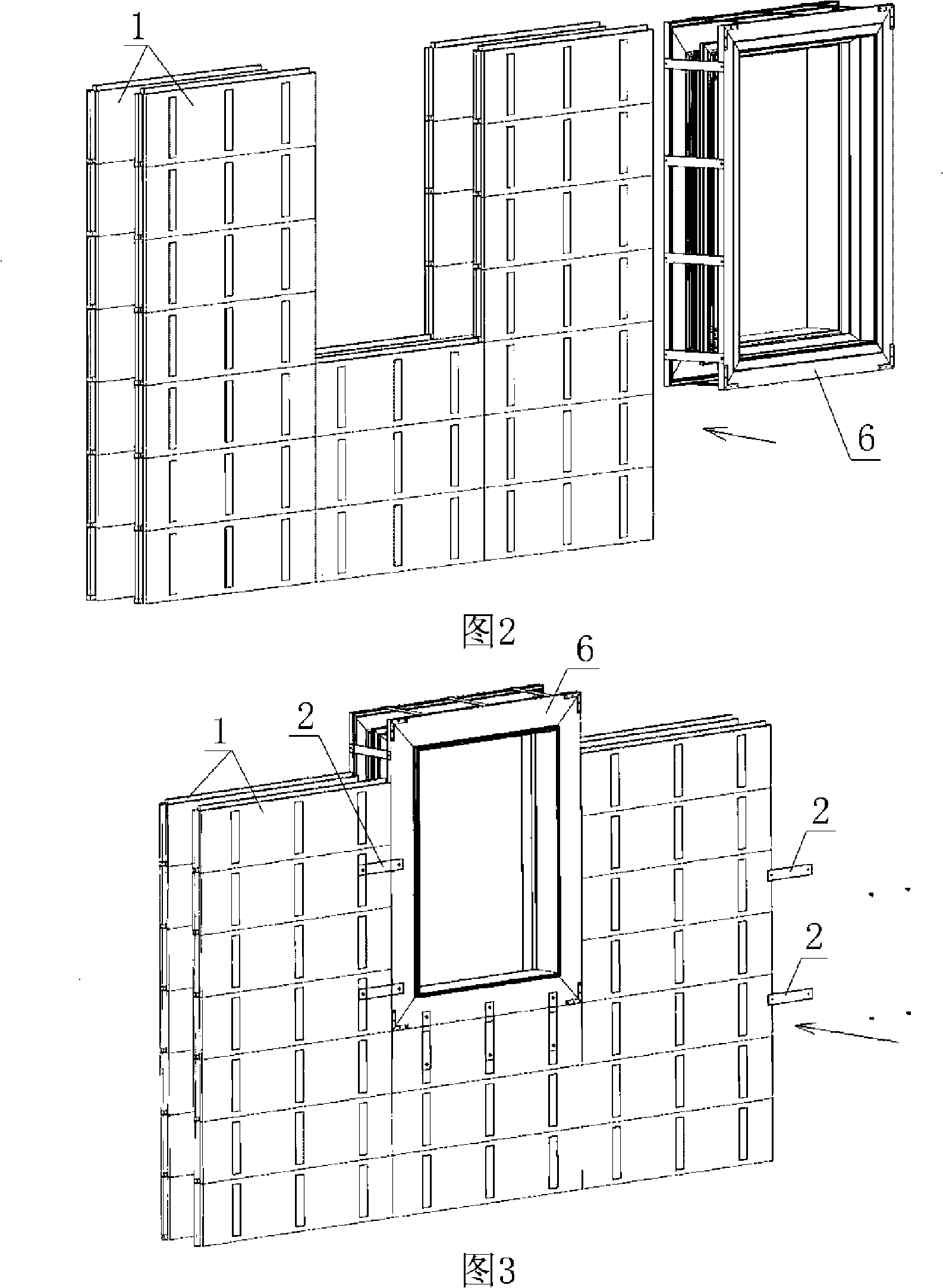

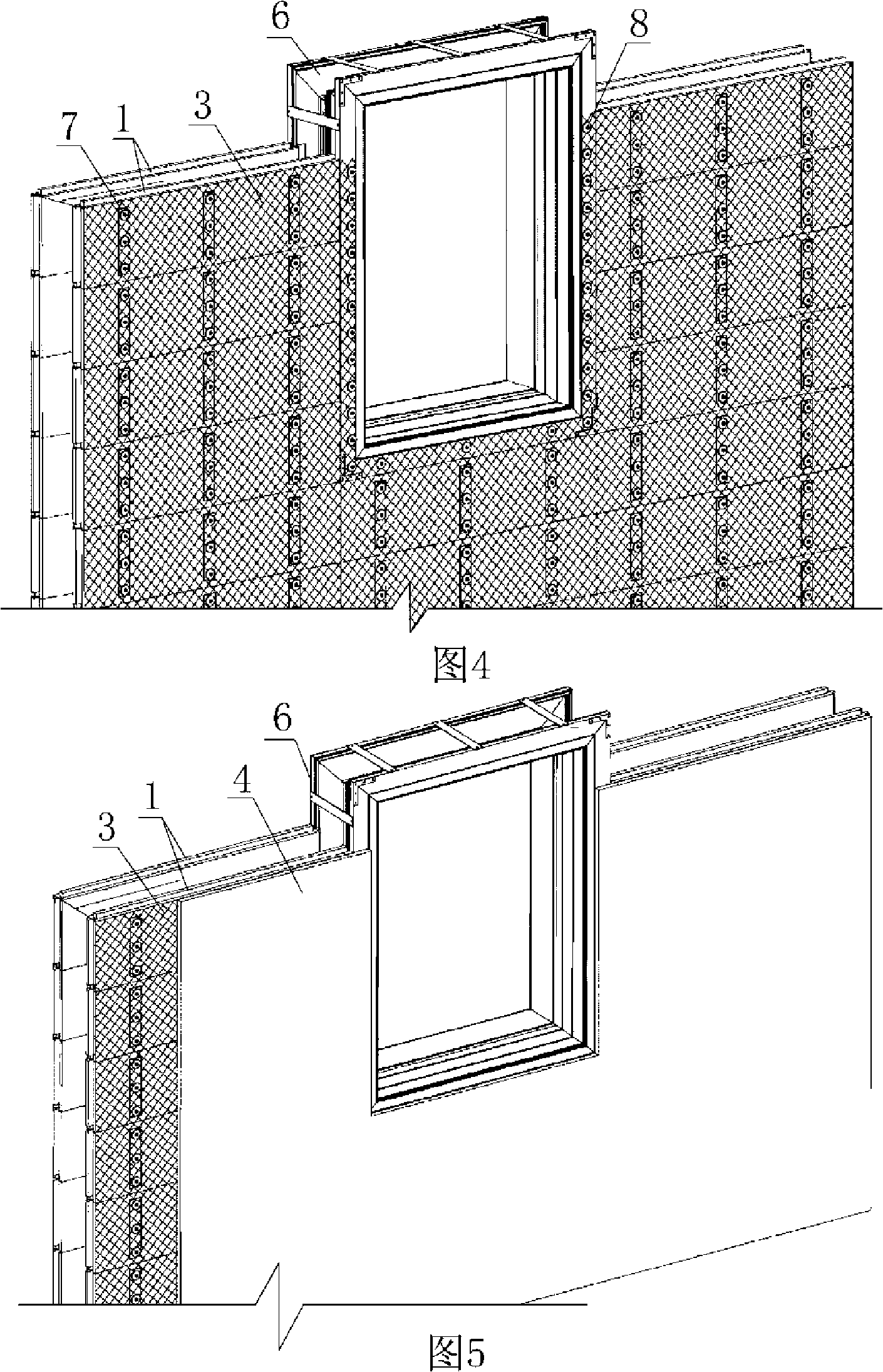

[0041] Examples see figure 1 , as shown in Figure 912, the molds for the wall door and window openings of this composite thermal insulation concrete structure system are arranged around the opening by the opening inner formwork 6.1, the opening outer formwork 6.2 and the sealing plate 6.3. The above-mentioned opening inner formwork, opening outer formwork and The sealing plate is made of polystyrene foam or other foam plastics, and is enclosed and connected in a U-shape on the cross-section of the opening. The U-shaped opening faces the side of the wall, and the inner formwork of the opening and the outer formwork of the opening are between the U-shaped openings. Connected with positioning strip 6.4, the inner formwork of the hole and the outer formwork of the hole are tightly connected with the thermal insulation wall formwork 1 by the limit piece 2 respectively, and the sealing plate is located at the U-shaped bottom, close to the frame plate of the hole. For making door, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com