Liquid crystal display panel and liquid crystal display panel assembling method

A liquid crystal display panel and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as the gravity margin of spots displayed on the liquid crystal display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

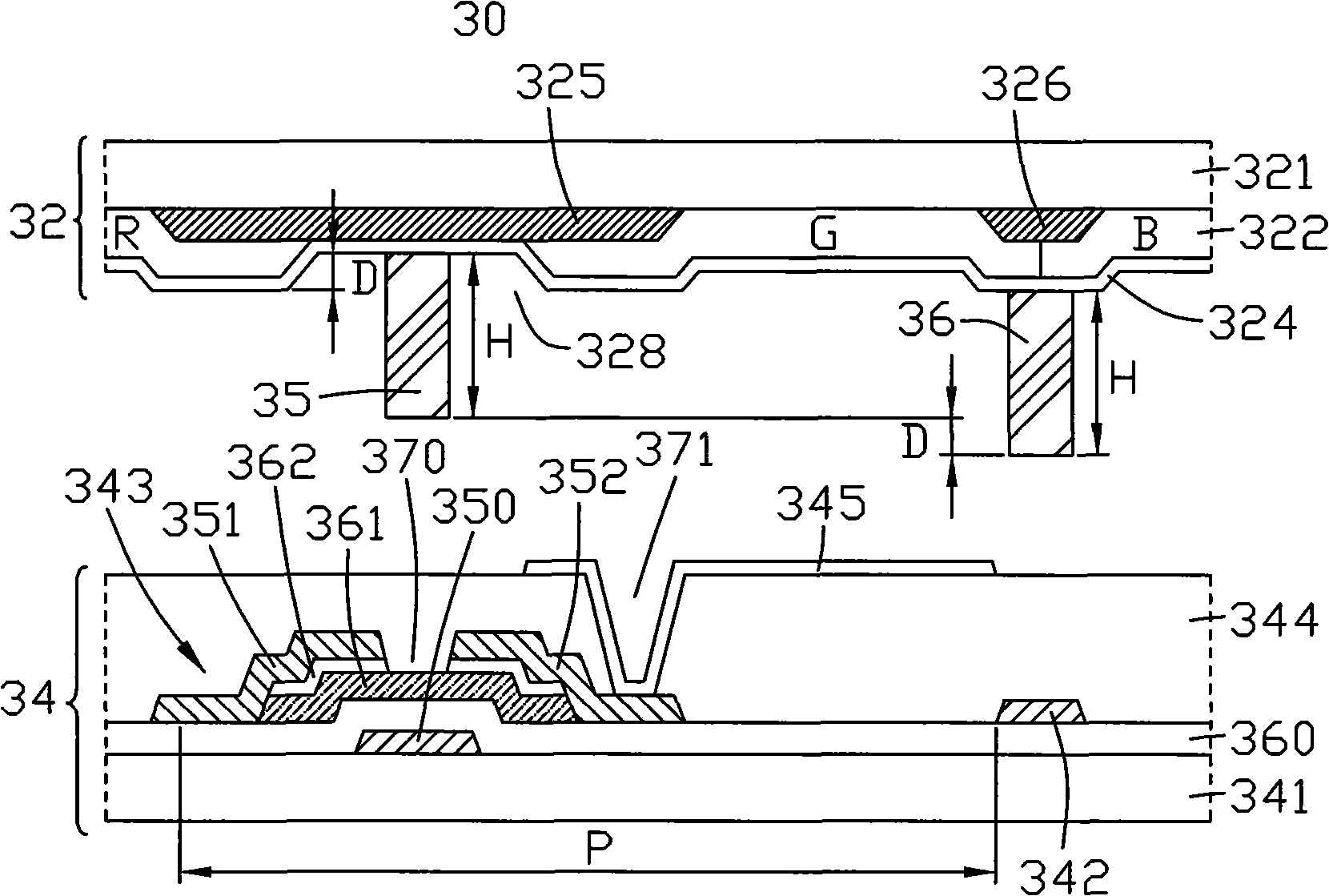

[0027] see Figure 4, is a schematic cross-sectional view of the first embodiment of the liquid crystal display panel of the present invention before assembly. The liquid crystal display panel 30 includes a color filter layer substrate 32 , a thin film transistor substrate 34 , a plurality of first columnar spacers 35 and a plurality of second columnar spacers 36 . The color filter substrate 32 is disposed opposite to the TFT substrate 34 , and the plurality of first columnar spacers 35 and the plurality of second columnar spacers 36 are located between the two substrates 32 , 34 .

[0028] The thin film transistor substrate 34 includes a first base 341 and a thin film transistor array (not shown) disposed on the surface of the first base 341 . The thin film transistor array includes a plurality of scanning lines arranged horizontally (not shown in the figure), a plurality of data lines 342 vertically insulated and intersecting with the scanning lines (only one of them is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com