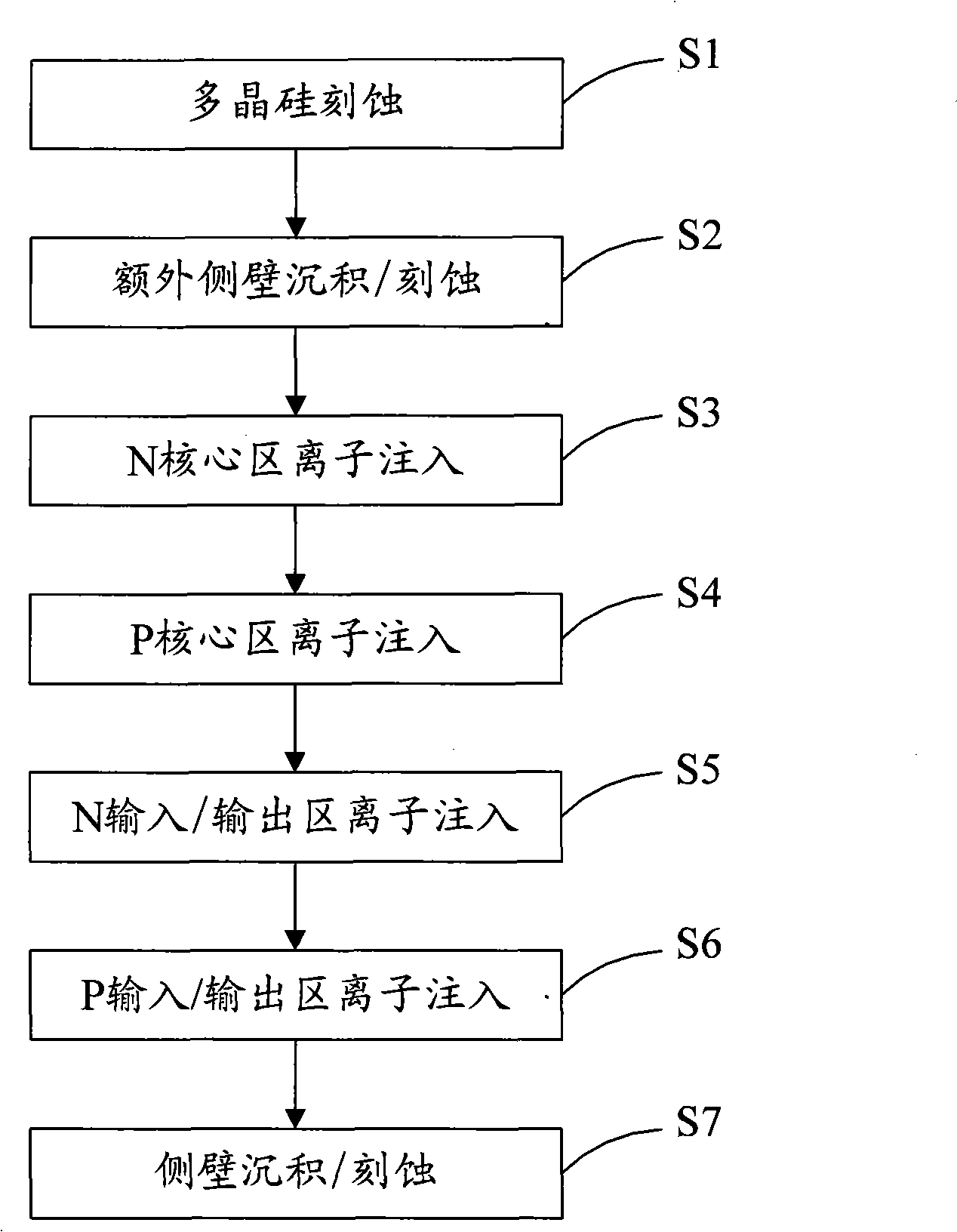

Manufacturing process of input/output device

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of inability to obtain a graded junction, low temperature, etc., and achieve the effect of preventing hot carrier effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The manufacturing method of the input / output device of the present invention will be further described in detail below.

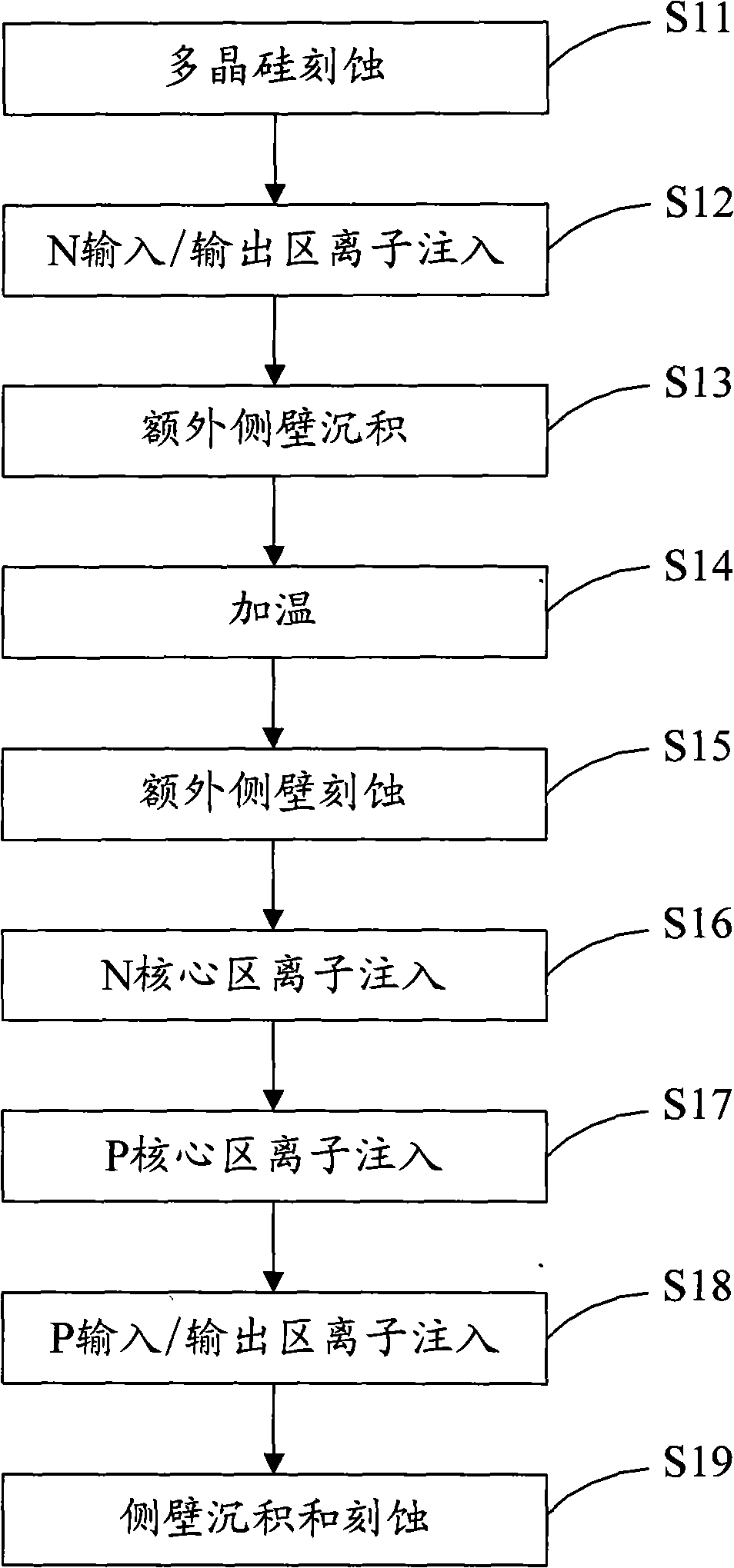

[0013] The biggest difference between the method of the present invention and the prior art is that the N I / O ion implantation step is performed in advance before additional sidewall deposition / etching. There are two reasons for advancing this step: 1) The hot carrier effect has a greater impact on N, but relatively less impact on P; 2) The working voltage of the I / O area is higher than that of the Core area, and it is more susceptible to heat load flow effect. Therefore, N I / O ion implantation is advanced.

[0014] see figure 2 In the method of the present invention, after polysilicon etching S11 is completed, step S12, N I / O ion implantation, is performed first, and the ion implantation used in the present invention is lightly doped drain (Light Doped Drain, LDD) ion implantation, and then, An additional sidewall deposition step S13 is performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com