Disposal method and equipment for exhaust gas from combustion system

A technology of waste gas treatment device and combustion device, which is applied in combustion method, combustion product treatment, gas treatment and other directions, can solve the problems of carbon dioxide recirculation, high temperature of combustion furnace, etc., and achieves reduction of driving energy, simple device structure, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

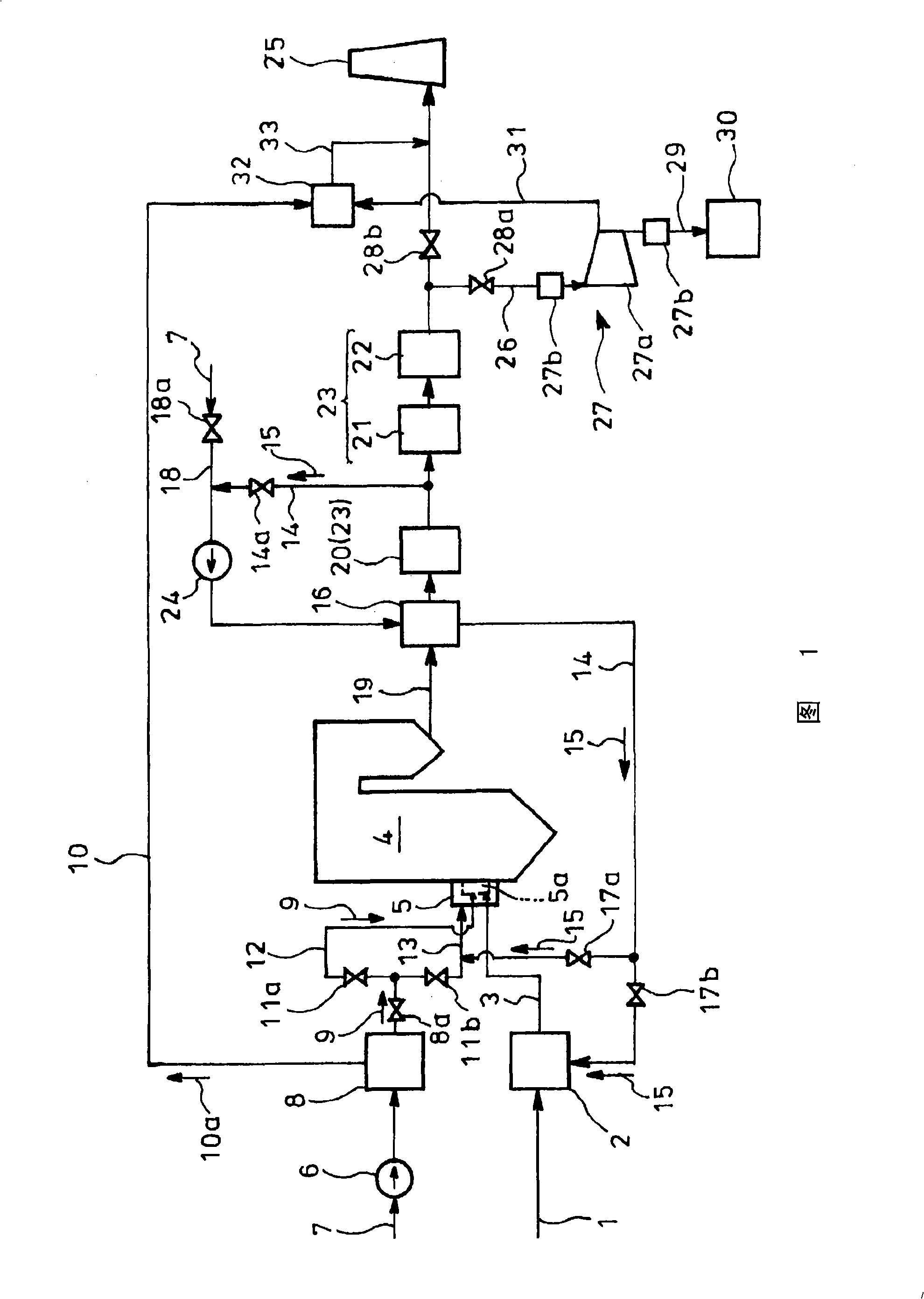

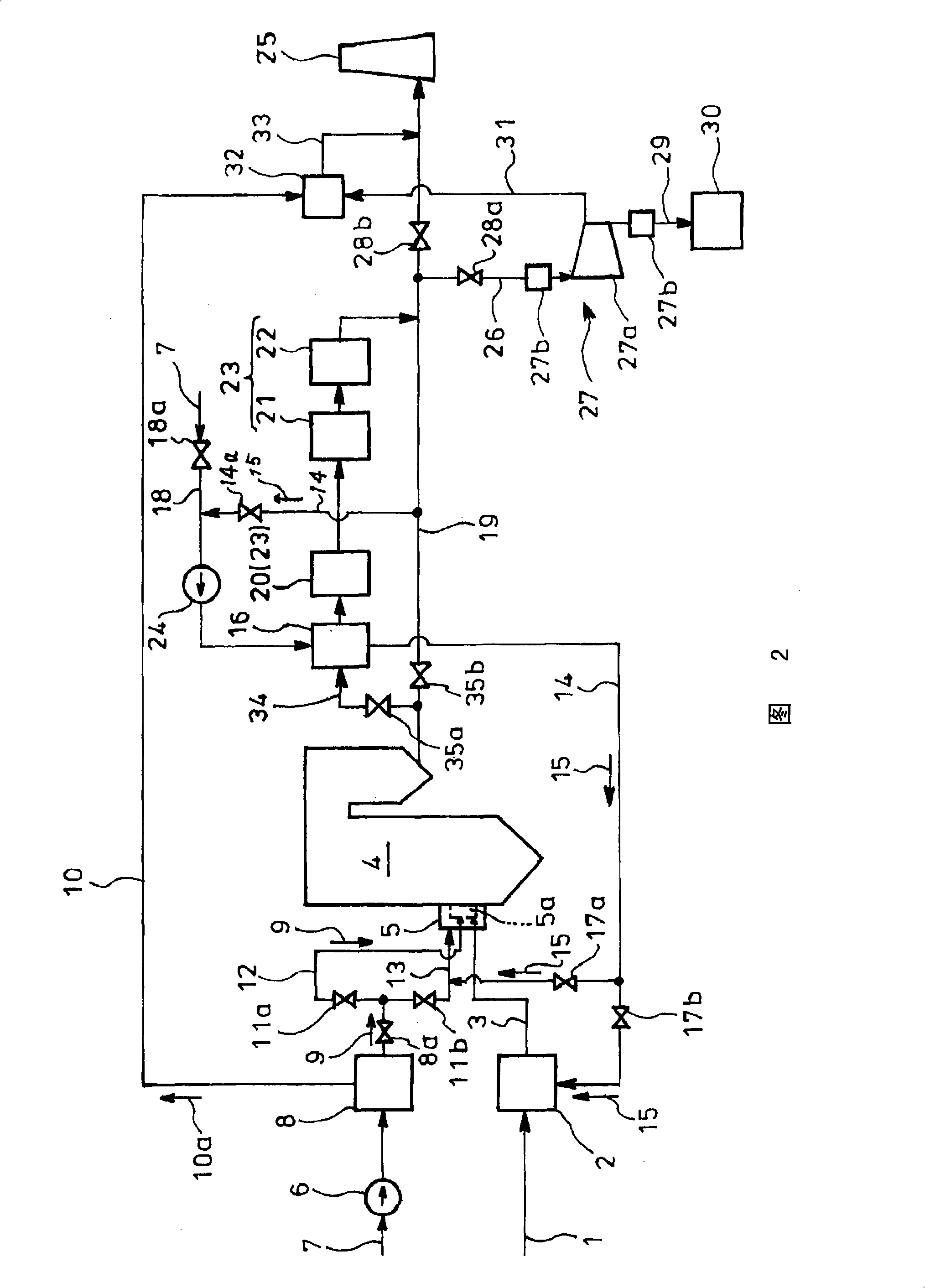

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0058] Fig. 1 is a schematic flow diagram showing an example of an apparatus for implementing the present invention, in which coal 1 as fuel is pulverized by a mill 2 used as a fuel supply means to form pulverized coal 3, and is supplied in a wind box 5 of a combustion furnace 4 (boiler) Has burner 5a. The air 7 from the blower 6 is supplied to the oxygen separation device 8 and separated into oxygen 9 and other nitrogen-based gas 10a, and the generated oxygen 9 passes through the regulator 8a, and then is shunted to the direct flow through the oxygen flow regulator 11a, 11b. A part of the oxygen 9 is directly supplied to the burner 5 a through the direct supply line system 12 and the mixed supply line system 13 . On the other hand, the remainder of the oxygen 9 is mixed with a part of the recirculation gas 15 preheated in the air preheater 16 described later and guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com