Eciprocating relay type mad-scraping method and device

A mud scraper and scraper technology, applied in separation methods, chemical instruments and methods, settling tanks, etc., can solve problems such as increasing the number of equipment, occupying an area and investment, difficulty in restarting the car, and limiting the working area, etc., to achieve The effect of simple structure, long service life and large working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be applied to multiple types of concentrators. In the embodiment, the description of further development in conjunction with the concentrator is as follows:

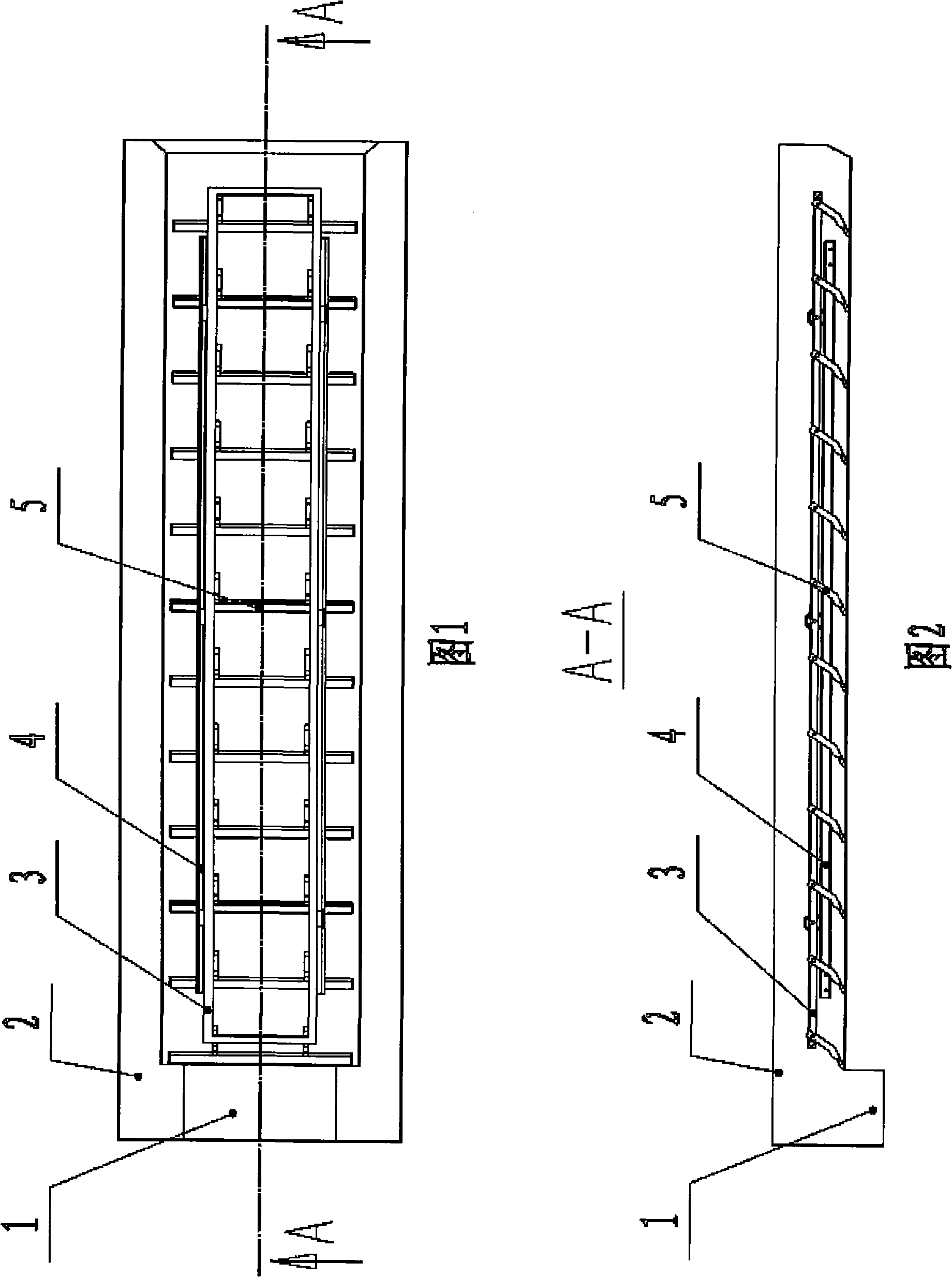

[0026] In the embodiment, Fig. 1 and Fig. 2 show a thickener mud scraper system, which includes a common thickener pool 2, a collection pit 1 and the mud scraper of the present invention. The mud scraping method described in the present invention is a reciprocating relay method. The mud scraper is a plurality of scrapers 5 equidistantly suspended on a rail car 3, and the scrapers 5 are naturally dragged and dropped to the bottom of the pool at a certain angle, and the rail car 3 is dragged by a traction device to reciprocate along the track 4. When there is a certain thickness of sediment at the bottom of the pool, when the rail car 3 moves back away from the collection pit 1, the scraper 5 is pulled out and dragged back along the mud surface; when moving forward, the scraper 5 goes deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com