Automatic stamping machine and programmed control method

An automatic stamping machine and stamping technology, which is applied in printing, stamping, etc., can solve the problems of undisclosed and optimized structure, optimized performance, etc., and achieve the effects of avoiding motor damage accidents, standard stamping, and preventing motor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

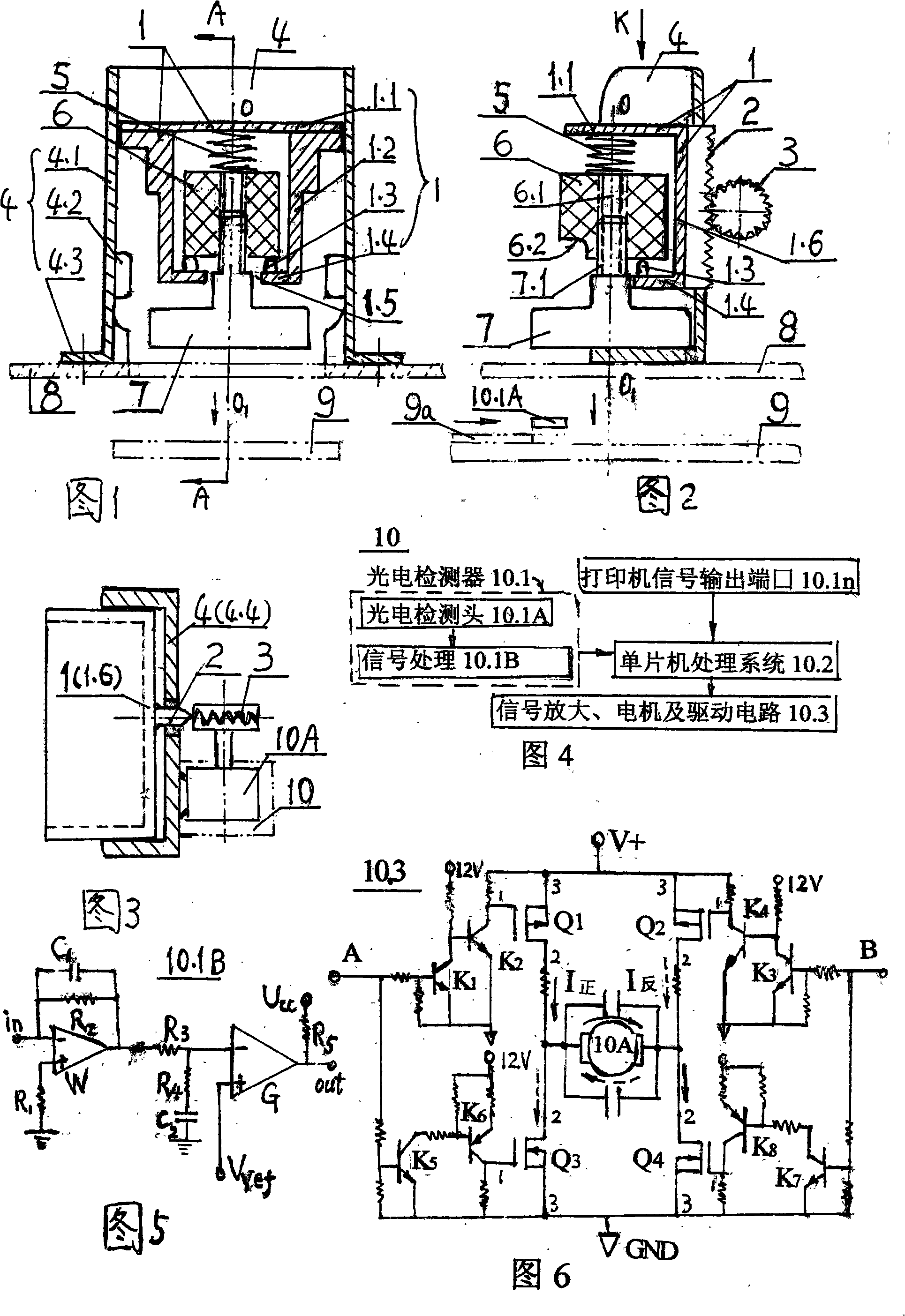

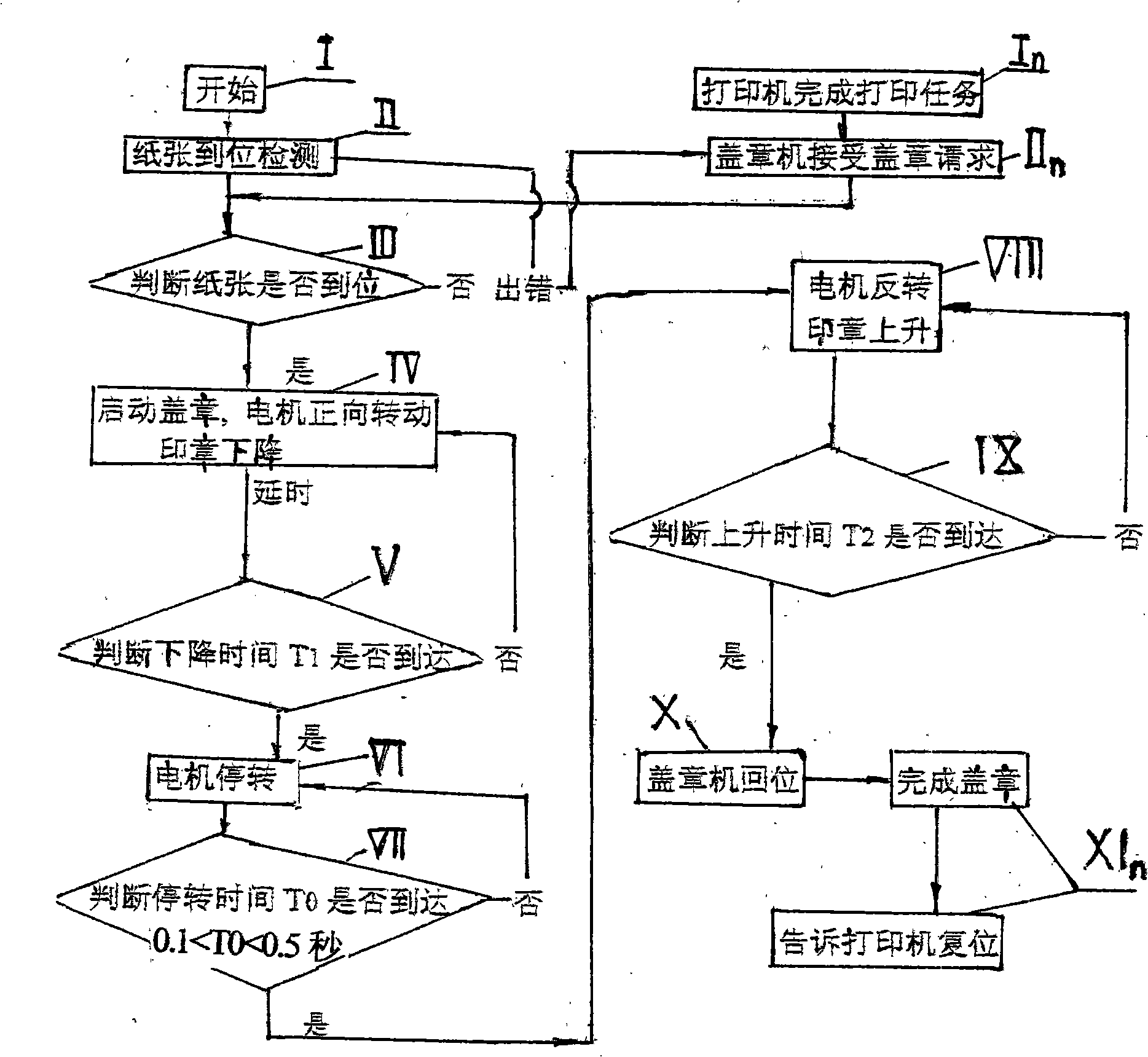

[0023] Embodiment 1: see Fig. 1~ Figure 7 , Figure 9 .

[0024] As shown in Figures 1 to 2, the transmission bracket 1 is provided with a top plate 1.1, a lower plate 1.4 and two side plates 1.2 connecting them, and a rear plate 1.6 may also be provided. Place stage clip 5, seal handle 6 and seal 7 successively under top plate 1.1, seal is connected with seal handle threaded hole 6.1 by threaded rod 7.1 on the upper end, the two are connected as a whole. The card 1.3 is fixed on the bottom plate 1.4 of the transmission bracket, and the stamping handle 6 is clamped between the upper plane clip spring and the lower plane card 1.4. See Fig. 1, lower plate 1.4 has breach 1.5, so that when stamping handle 6 is taken off and adds stamp oil, stamp can be taken out simultaneously. As shown in Figure 2, there is a gap 6.2 below the outer height of the stamping handle, which is convenient for taking out the stamping handle by hand, and the threaded hole 6.1 of the stamping handle is...

Embodiment 2

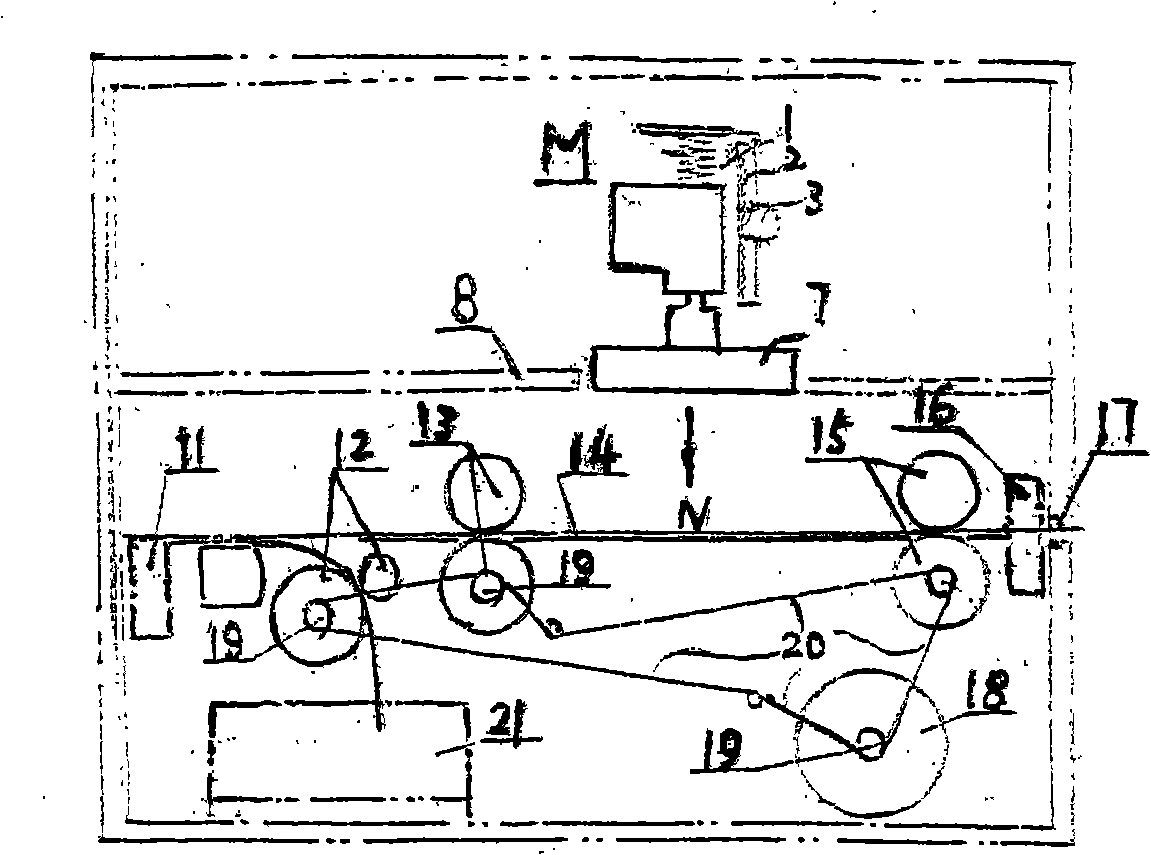

[0030] Embodiment 2: see Fig. 1~Fig. 4, Fig. 6~ Figure 8

[0031] The automatic stamping machine in Embodiment 2 is used in conjunction with the printing, paper separating and paper feeding systems of the automatic payment and billing terminal. Except that the automatic control device 10 and the program control method are slightly changed, all the others are identical to Embodiment 1. The 'upper program device' described in the above program in Embodiment 2 is a 'printer'. The differences are as follows: (i). See Fig. 4, the automatic control device 10 is composed of a printer signal output port 10.1n, a single-chip microcomputer processing system 10.2, a signal amplifier, a motor and a driving circuit 10.3. The photodetector 10.1 in Embodiment 1 is replaced by a printer signal output port 10.1n. ii. see Figure 7 , complete the printing task with step In. printer respectively; IIn stamp machine accepts stamp request; Alternative embodiment 1 step I starts and II paper in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com