Magnesium alloy sleeping-berth of trolley coach

A rail passenger car and magnesium alloy technology, applied in the sleeper field of rail passenger cars, can solve the problems of large volume, inconvenient folding, and large vibration of the turning mechanism, and achieve the effects of low processing cost, easy recycling, and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

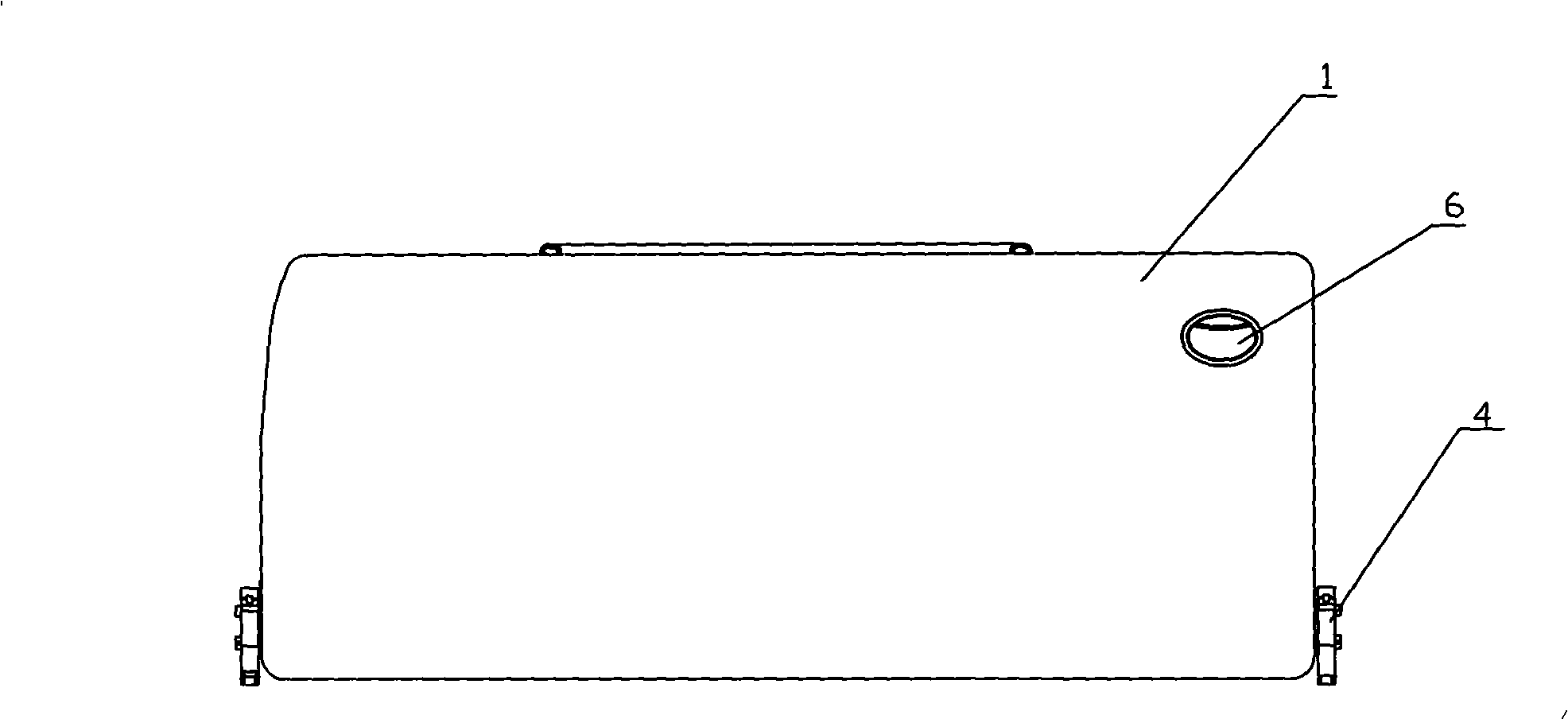

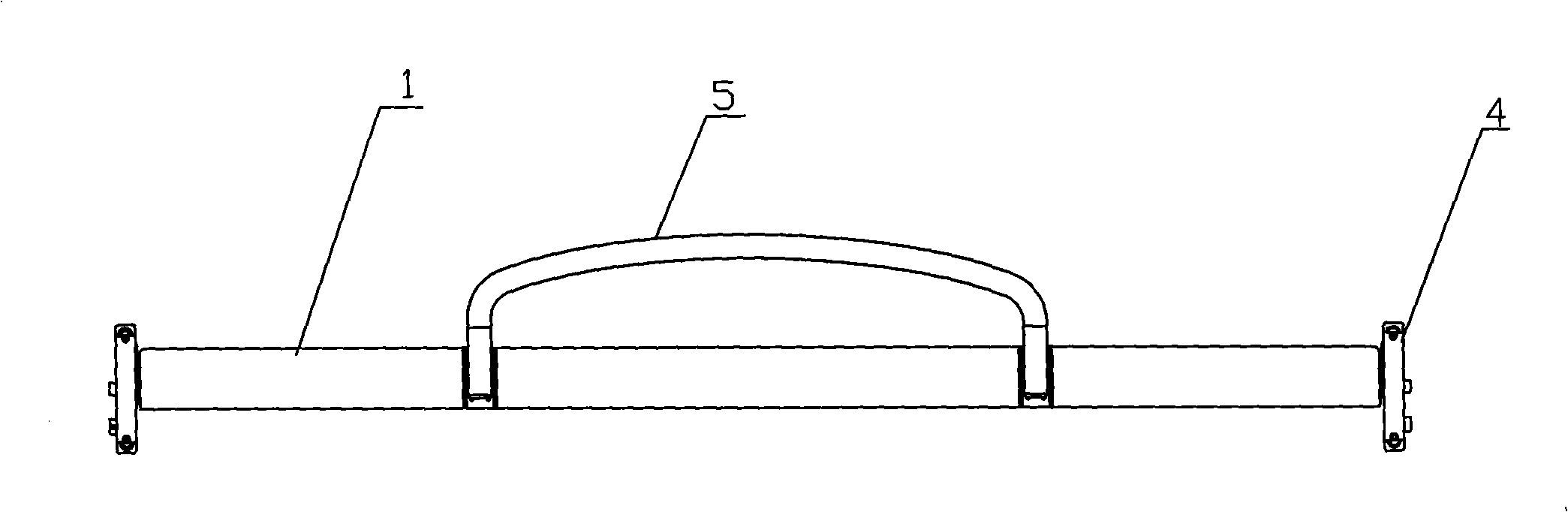

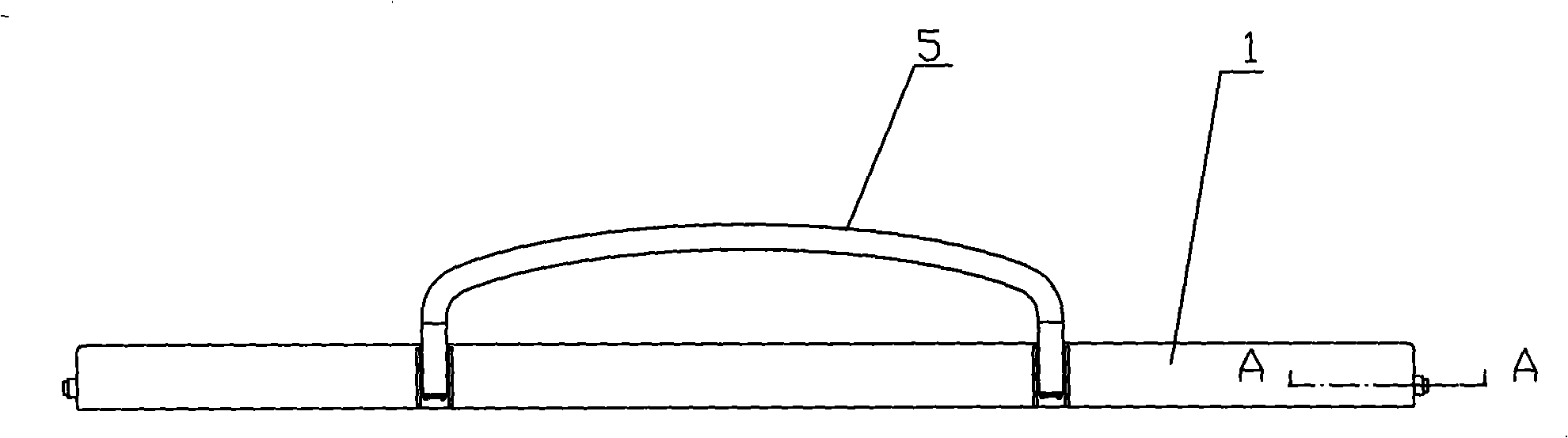

[0021] Such as Figure 1-8 As shown, the rail passenger car magnesium alloy sleeper of the present invention comprises a paving body 1, is fixed with the wall bodies 2 on both sides and is fixed with a rotating shaft seat 4 through an inner hexagon screw 3, and a protective railing and a handle 6 are installed on the paving body, and the paving body 1 includes a magnesium alloy skeleton 7, the magnesium alloy skeleton 7 protrudes outwards the nylon sleeve 8 of the rotating shaft and the nylon sleeve 9 of the positioning shaft, the rotating shaft 10 is arranged in the nylon sleeve 8 of the rotating shaft, and the positioning shaft is provided in the nylon sleeve 9 of the positioning shaft The shaft 11 and the rotating shaft 10 are connected between the rotating shaft seat 4 and the magnesium alloy skeleton 7, a compression spring 12 is set on the positioning shaft 11, and a gas spring brake wire is connected to the rear end of the positioning shaft 11, and the gas spring brake w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com