Coating barrier film and method for preparing same

A technology of isolation film and coating, applied in the field of coating isolation film and its preparation, can solve the problem of no product on the market, and achieve the effect of great promotion and application value, strong applicability and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

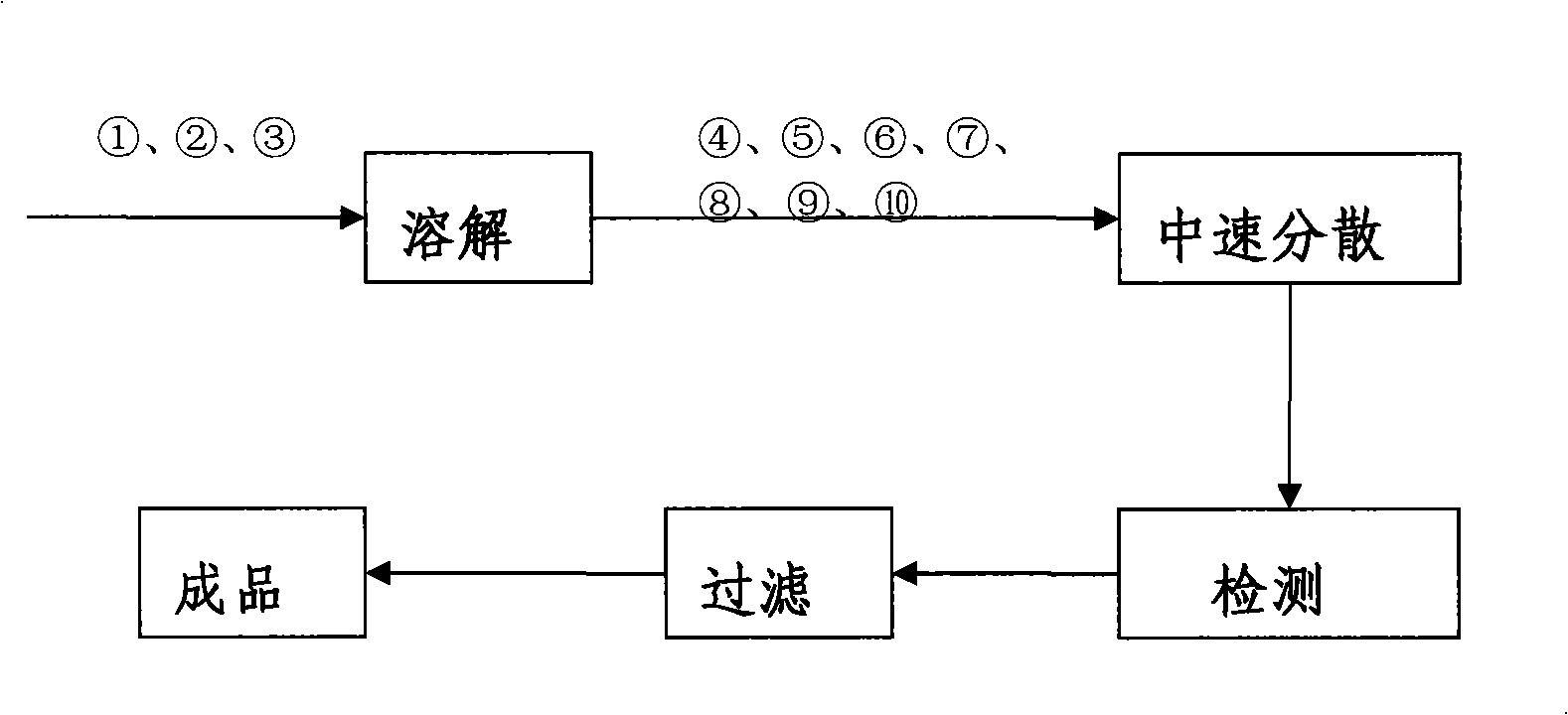

[0009] The technical content of the present invention will now be described in detail in conjunction with the accompanying drawings.

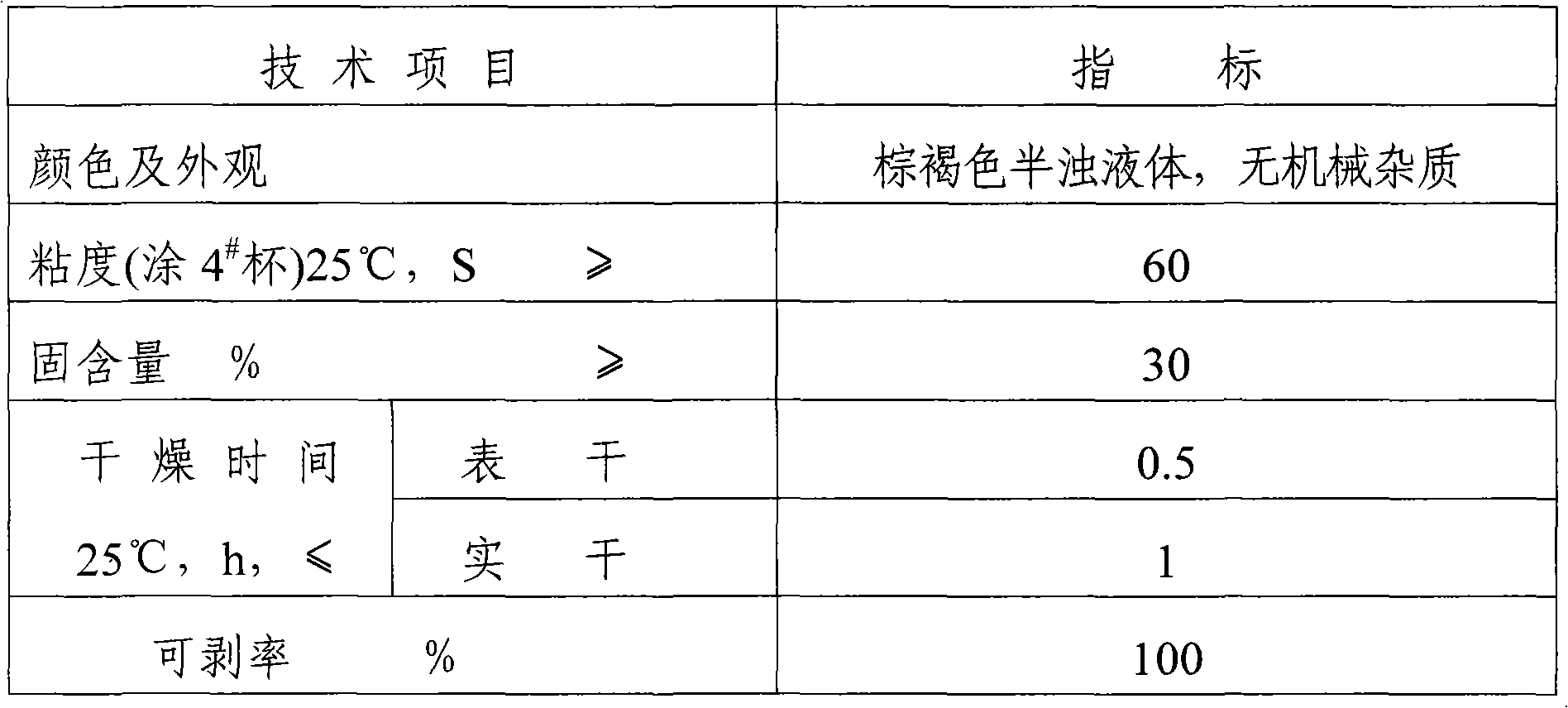

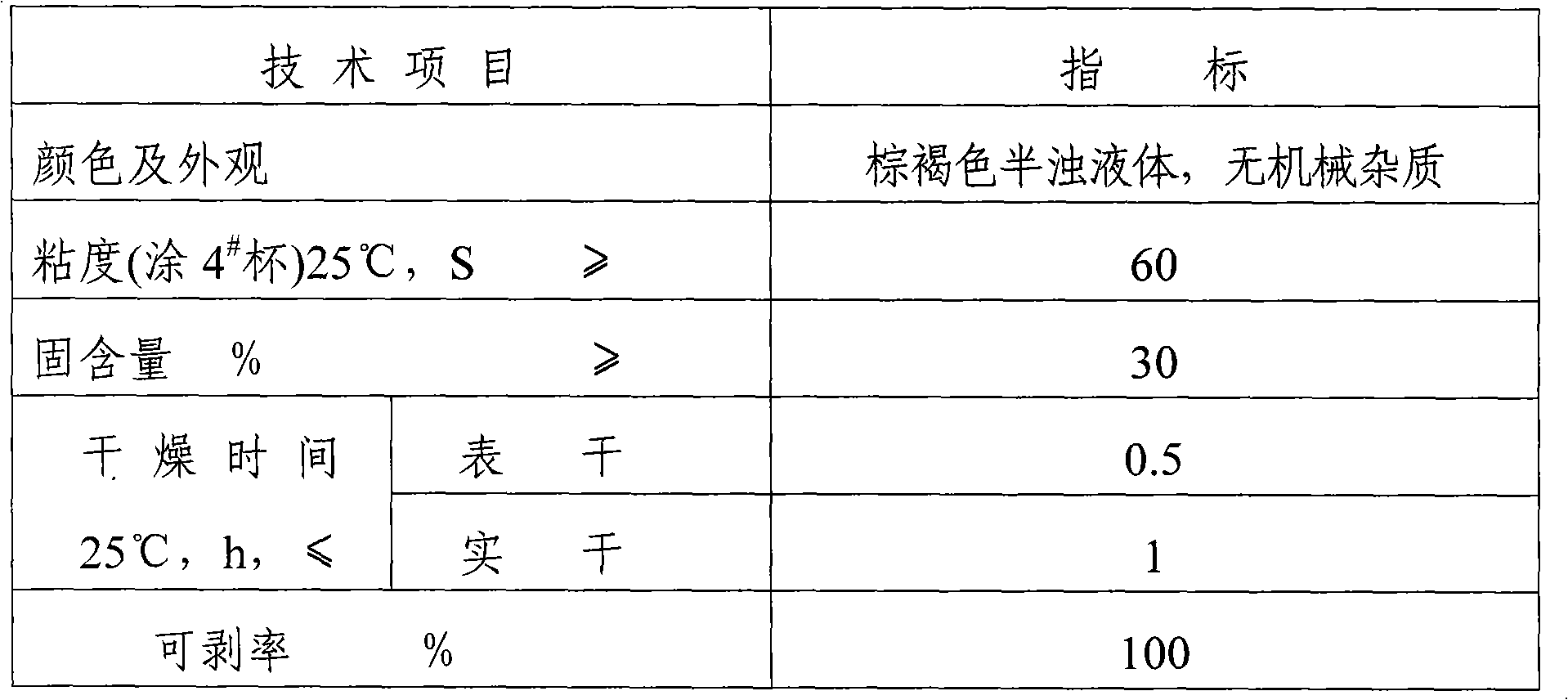

[0010] 1. the raw material and percentage by weight thereof that the present invention selects are:

[0011] ① Polyvinyl chloride (PVC): 7.3%-9.3%;

[0012] ②High chlorinated polyethylene (HCPE): 7%-9%;

[0013] ③Xylene: 67.9%-69.9%;

[0014] ④ Engine oil: 9%-11%;

[0015] ⑤ Calcium-based fat: 0.07%-0.09%;

[0016] ⑥Sodium-based fat: 0.06%-0.08%;

[0017] ⑦Manganese naphthenate: 1.3%-3.3%;

[0018] ⑧Defoamer (BYK141): 0.01%-0.03%;

[0019] ⑨Leveling agent (BYK306): 0.01%-0.03%;

[0020] ⑩Dibutyl ester: 0.05%-0.07%.

[0021] 2. Concrete production process of the present invention is:

[0022] (1) Dissolving:

[0023] Add the raw materials ① polyvinyl chloride (PVC), ② high chlorinated polyethylene (HCPE) and ③ xylene into the paint mixing tank, start stirring to dissolve.

[0024] (2) Medium-speed dispersion:

[0025] Add the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com