Oxygen-enriched and all-oxygen combustion roller kiln combustion control method

A control method, a technology of full oxygen combustion, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of complicated pipelines and increase costs, and achieve high combustion rate, reduced work intensity, and high work reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

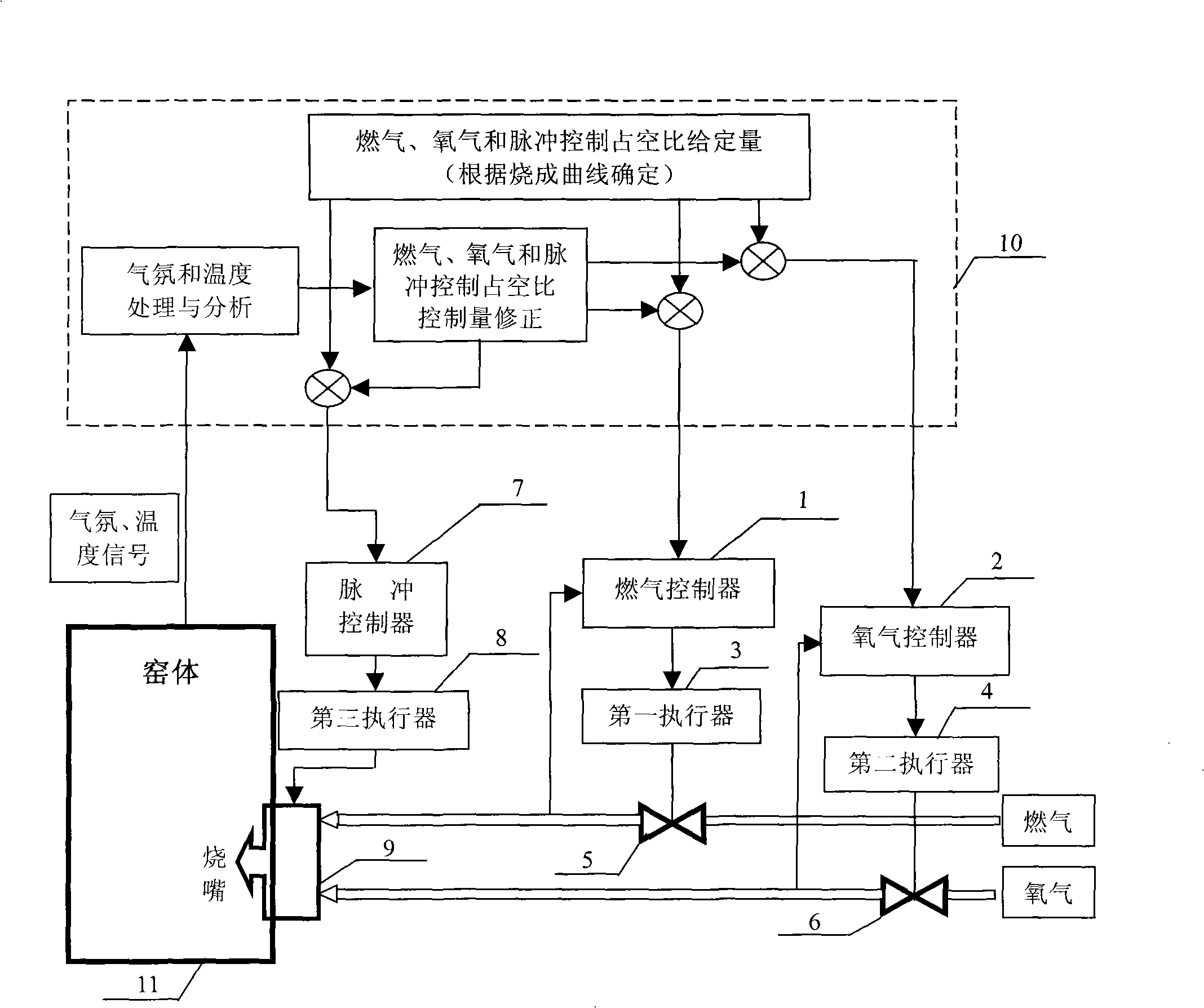

[0018] The combustion control method of the oxygen-enriched and full-oxygen combustion roller kiln provided by the present invention is: adopt the pulse combustion control method, keep the oxygen in the combustion atmosphere in the roller kiln at a volume content of more than 21%, and mix and burn with the gas , while automatically adjusting the ratio of oxygen to gas and the combustion time. details as follows:

[0019] (1) Through the closed-loop feedback control of oxygen and gas, the mixing ratio parameters of oxygen and gas are automatically adjusted; at the same time, according to the real-time information of the atmosphere and temperature in the kiln, the given amount of gas and oxygen determined by the firing curve is corrected, Get the real-time control amount of gas and oxygen given amount;

[0020] (2) Under the combined action of the above two control quantity signals, the gas controller and the oxygen controller can adjust the gas valve and the oxygen valve in re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com