Non-discharge desulfurization and comprehensive utilization method for sea water

A technology for seawater and desulfurized seawater, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of wasting seawater resources and improving power, aeration methods cannot ensure complete removal, extensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

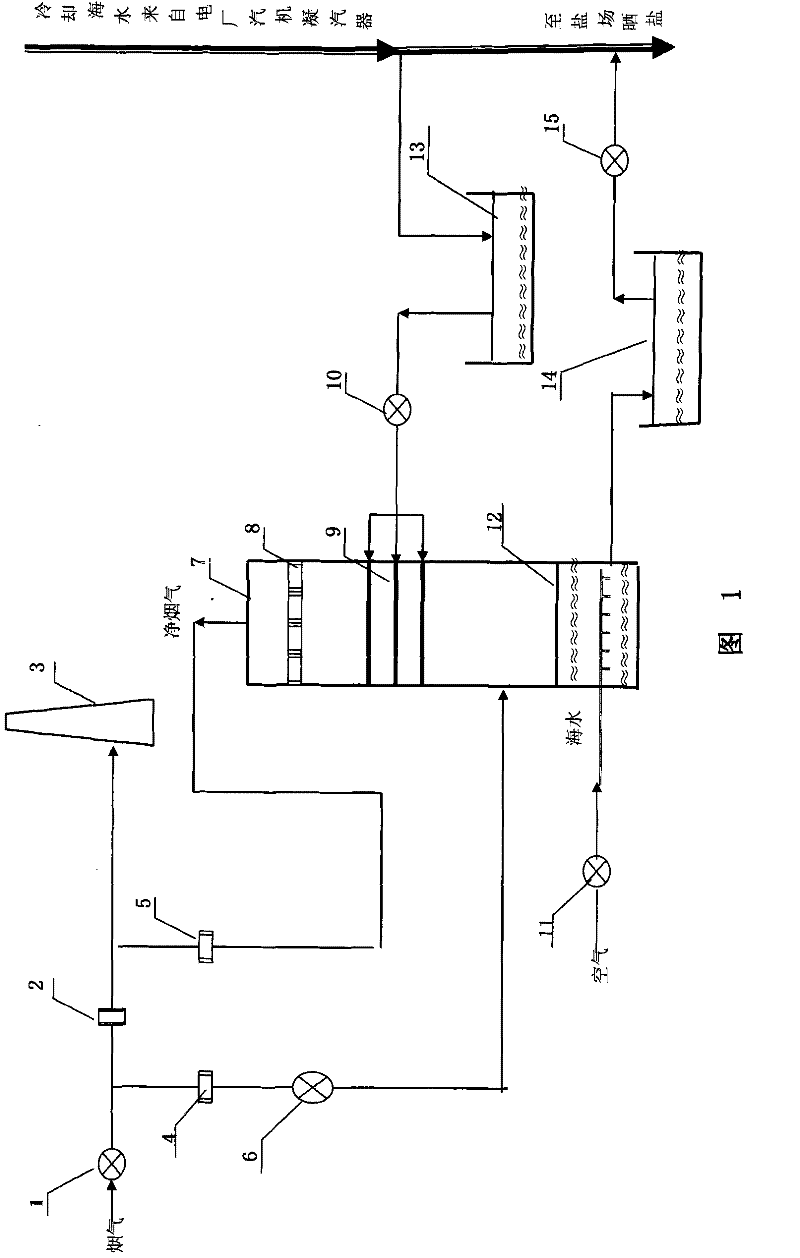

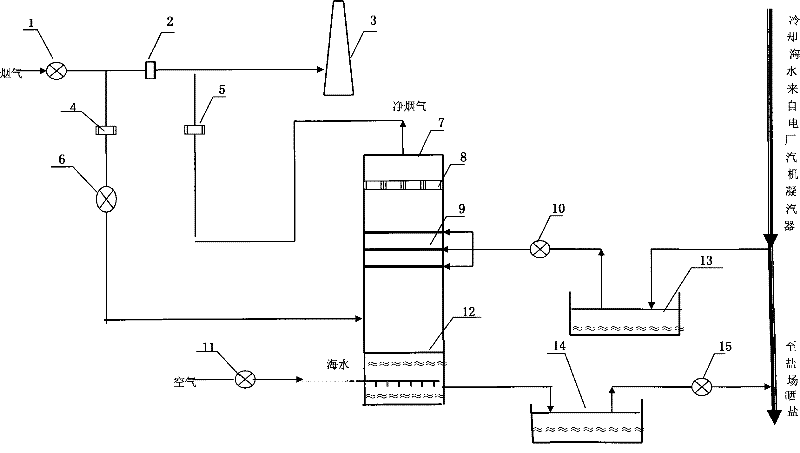

[0027] The technical process of the embodiment of the present invention is shown in figure 1 .

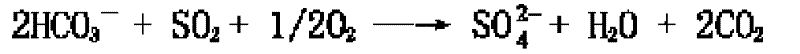

[0028] SO after dedusting 2 The concentration is 1150-1250mg / m 3 , The temperature is 70-80 ℃ boiler raw flue gas, from the induced draft fan 1 through the raw flue gas baffle 4, then pressurized by the booster fan 6 and then enter the absorption tower 7, from the weak alkaline after cooling of the steam turbine condenser of the power plant The seawater enters the spray layer 9 of the absorption tower through the seawater pool 13 by the seawater pump 10, and the raw flue gas contacts with the seawater countercurrently to absorb and neutralize the acidic SO in the flue gas 2 gas, SO 2 After being absorbed, sulfite ion SO is generated 3 2- , and enter the oxidation zone 12, in the oxidation zone sulfite ion SO 3 2- Oxidation reaction occurs with the air sent by oxidation blower 8 to generate more stable sulfate , and drive out the CO produced in seawater 2 , improve the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com