Mobile lifting mechanism

A lifting mechanism and mobile technology, which is applied in the direction of lifting devices, garbage conveying, loading/unloading, etc., can solve the problems of not being able to adapt to needs, moving, etc., and achieve the effect of simple structure, wide adaptability, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

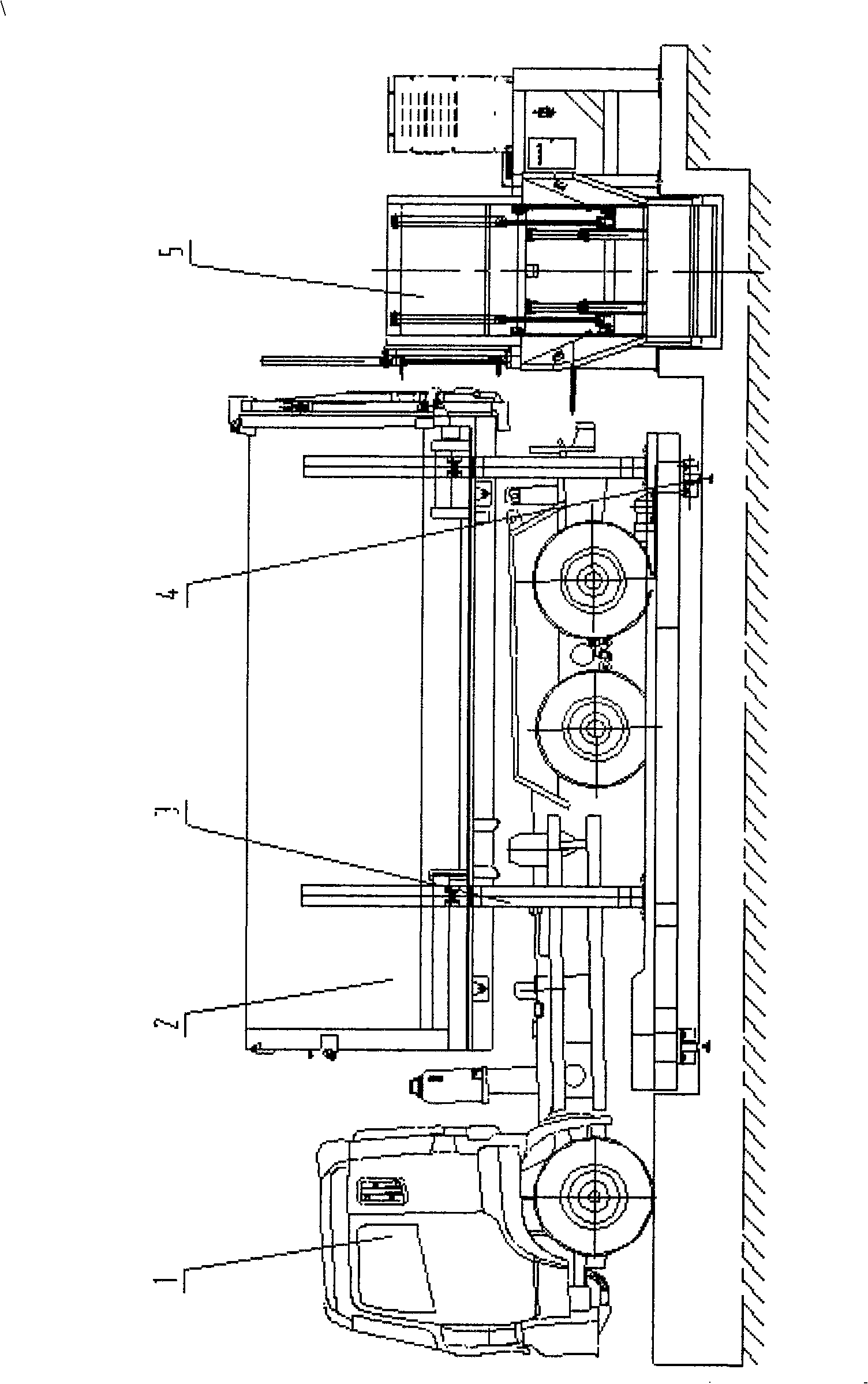

[0019] Such as figure 1 Shown: the present invention comprises chassis 1, rubbish container 2, lifting device 3, guide rail 4 and rubbish compressor 5.

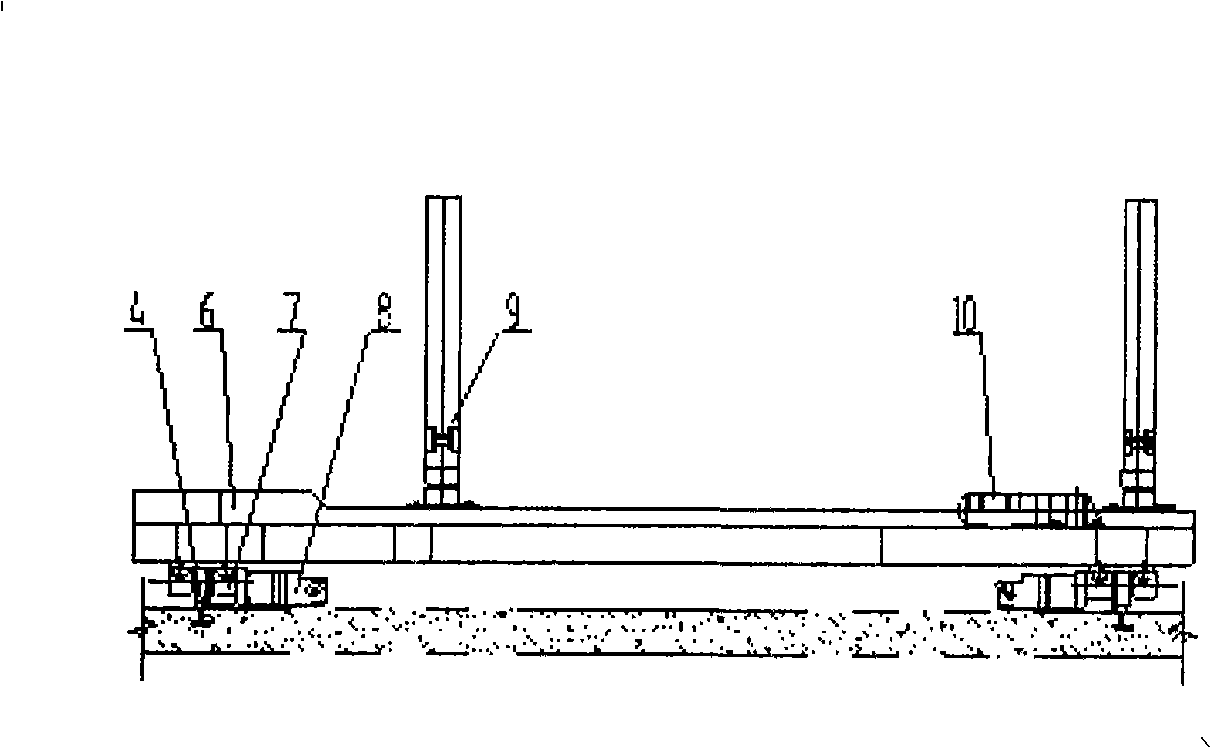

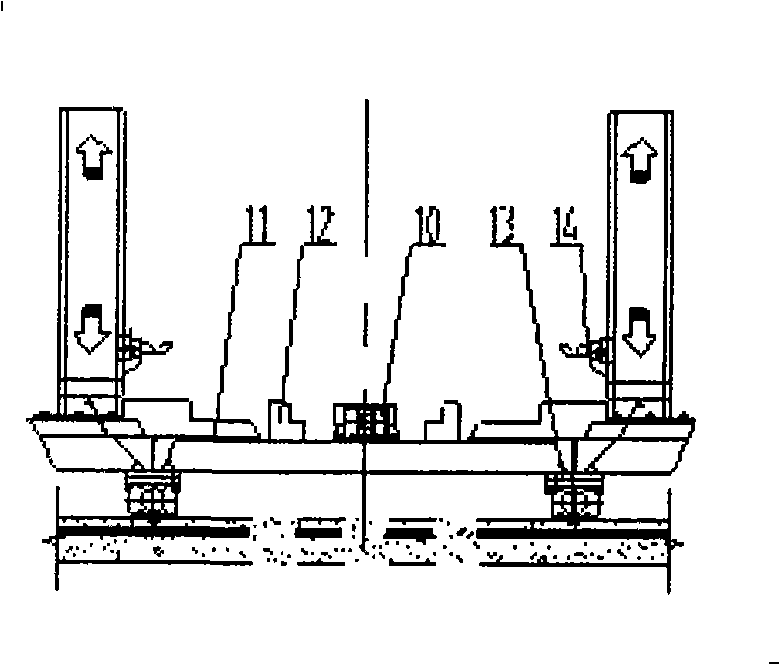

[0020] Such as figure 2 , image 3 , Figure 4 Shown: lifting device 3 comprises mobile vehicle frame 6, driving wheel 7, hydraulic motor 8, lifting tower 9, mobile tower 10, wheel guiding device 11, carriage support base 12, driven wheel 13 and tower arm hook assembly 14.

[0021] The chassis 1 is loaded with a garbage bin 2, which is responsible for the function of transporting garbage. The garbage compressor 5 is fixedly installed at an appropriate position on the ground in the garbage transfer station, and the guide rail is pre-buried at the position of the garbage compressor 5 collection port on the ground of the transfer station. , the length of the guide rail 4 is determined by the number of garbage compressors 5 or the number of garbage bins 2. The bottom of the mobile frame 6 is equipped with a driving wheel 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com