Photovoltaic modules and interconnect methodology for fabricating the same

A technology of photovoltaic cells and interconnection leads, applied in the field of solar cells, which can solve the problems of fragile battery strings, lack of resistance loss, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

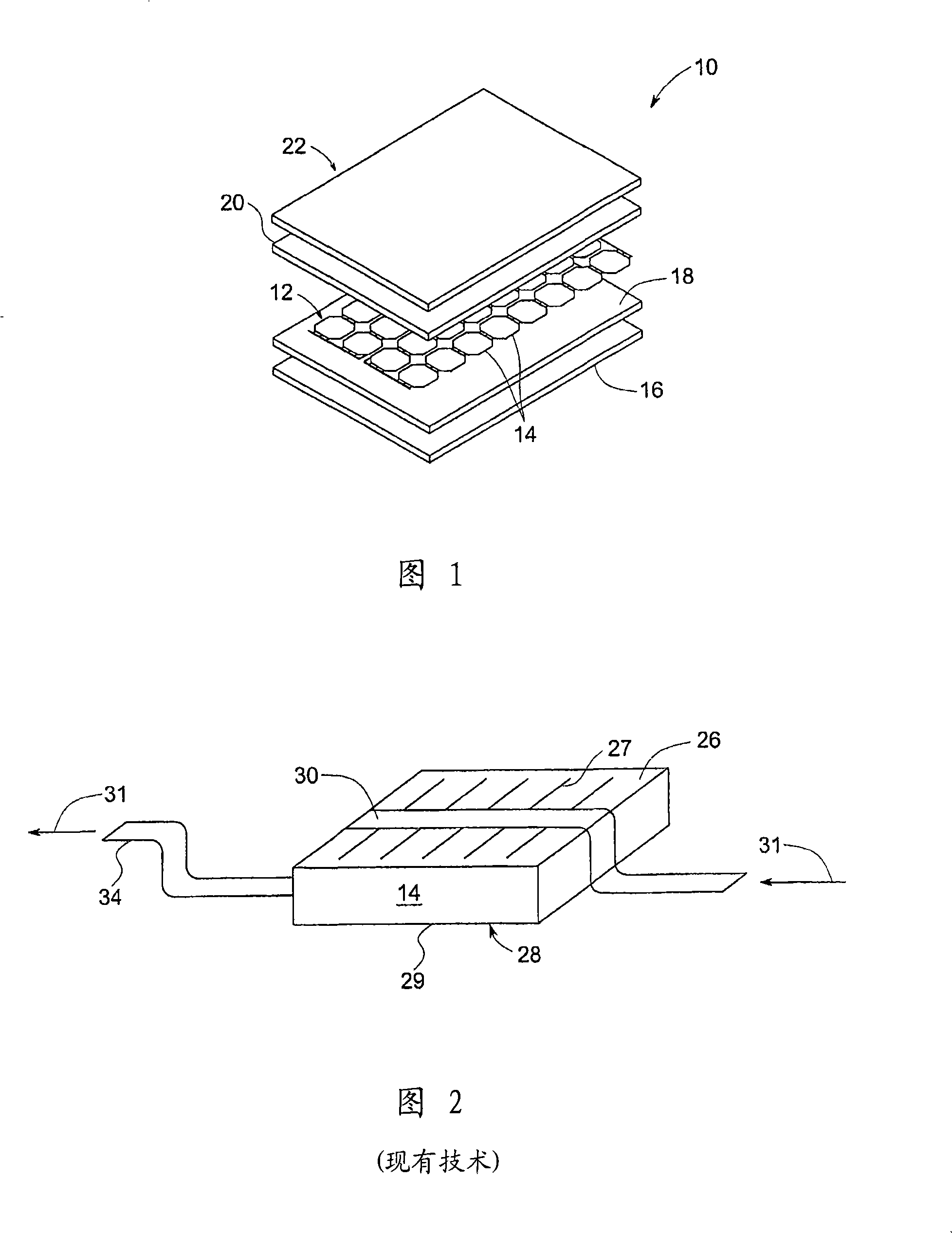

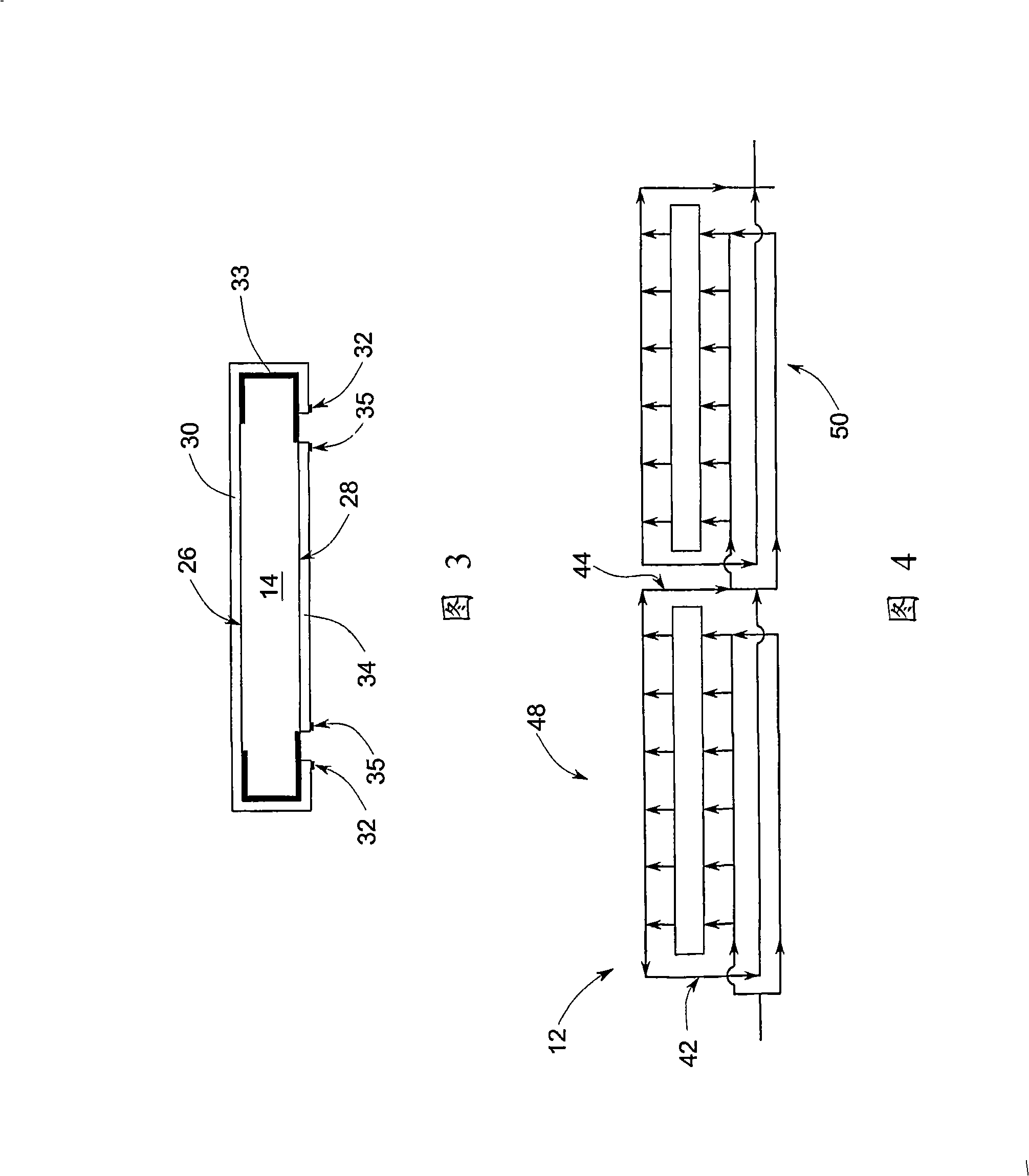

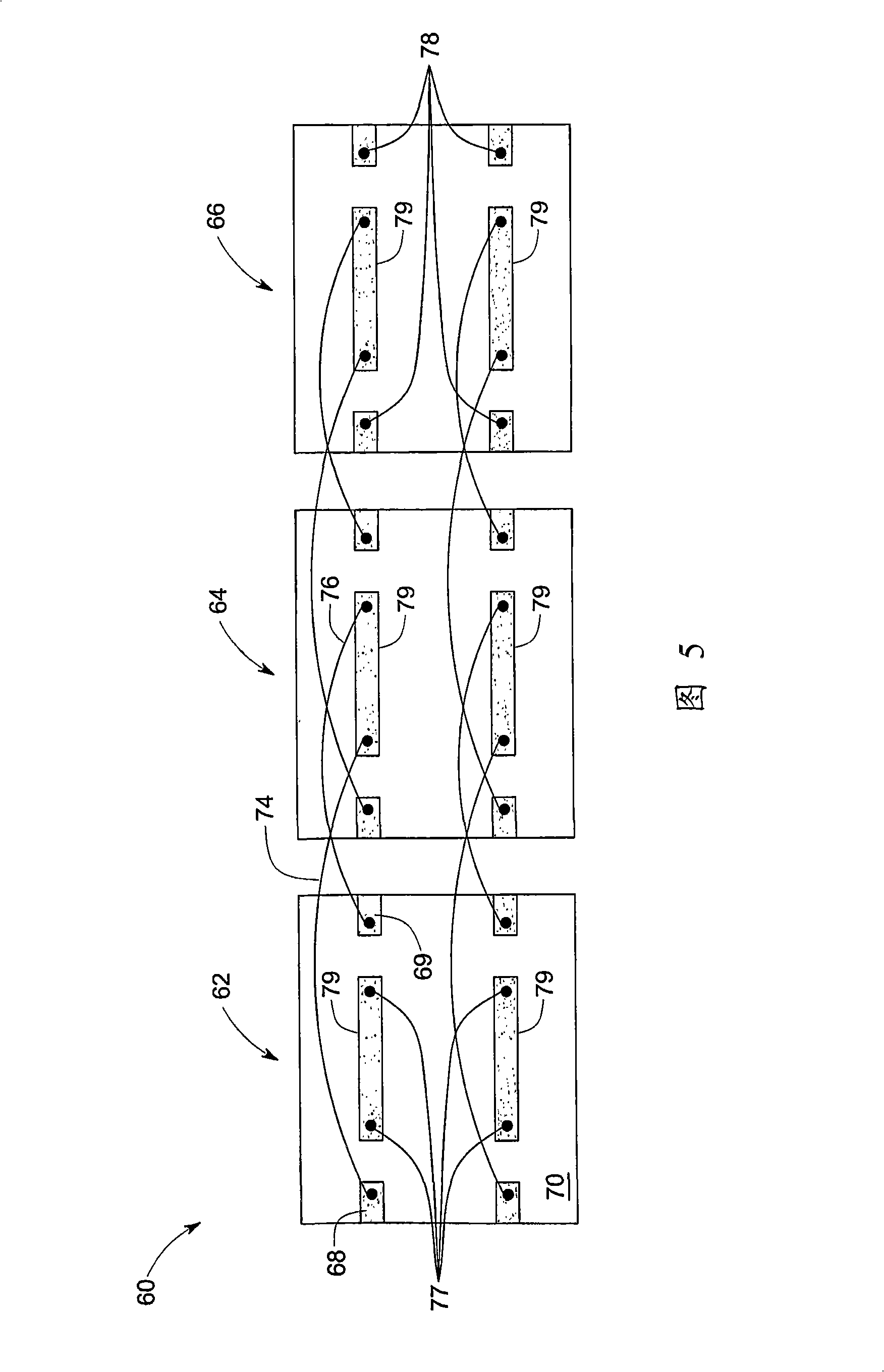

[0018] As discussed in detail below, embodiments of the present invention provide a solar cell array that includes a plurality of photovoltaic cells, where each photovoltaic cell includes a front side and a back side. The solar cell array also includes a plurality of front and back contacts on the front and back, respectively. One or more conductive tabs are electrically connected to the front contact and arranged to provide an electrical path from the front contact to the back of the photovoltaic cell. The solar cell array also includes a plurality of interconnecting wires connecting the tab on the back of each photovoltaic cell to at least one back contact on the back of another photovoltaic cell. In addition, other embodiments in which at least two current paths in parallel are provided on the back and front sides of each photovoltaic cell and methods of making arrays of photovoltaic cells are also discussed.

[0019] 1 is a schematic diagram of a photovoltaic (or solar) m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com