Medical magnesium alloy/calcium orthophosphate composite material

A composite material and magnesium alloy technology, applied in the field of absorbable medical magnesium alloy/calcium phosphate composite material, can solve the problems of limiting the application of magnesium alloy, inferior to the mechanical properties of bone tissue, generating hydrogen, etc., to reduce the corrosion degradation rate and improve the bone Effects of histocompatibility and osteoinduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

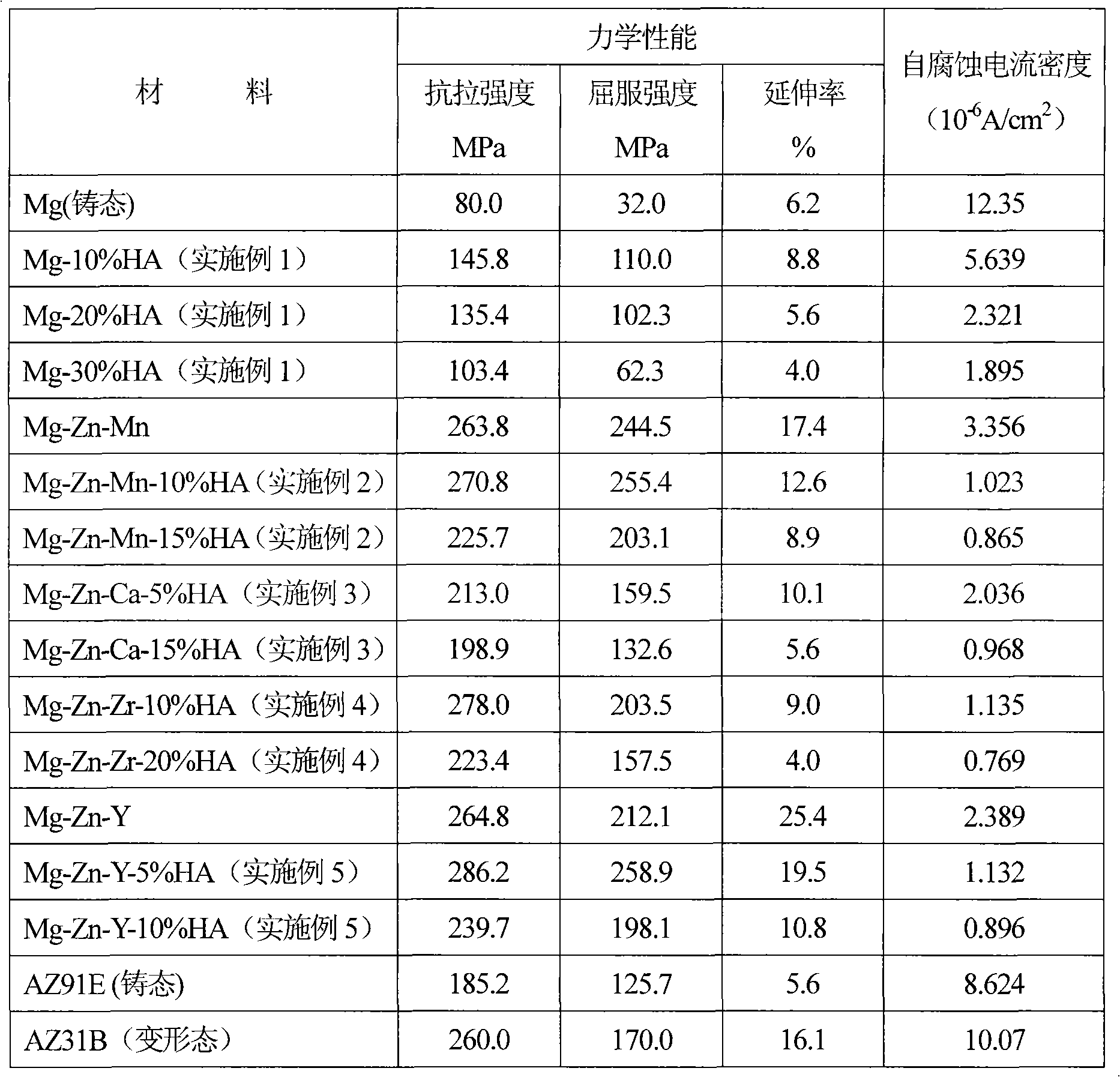

Embodiment 1

[0032] 40-100 μm high-purity magnesium powder and less than 10 μm calcium phosphate powder (50% hydroxyapatite + 50% β-calcium phosphate, weight ratio) are respectively 10%, 20% and 30% by weight of calcium phosphate powder The ratio is mixed by wet ball milling for 24 hours, and cold pressed to shape. Then in vacuum (vacuum degree is 1×10 -4 Pa) Sintering for 2 hours to form a sintered compact. Finally, it is extruded into rods under certain conditions.

Embodiment 2

[0034] Firstly, Mg-1.0Zn-0.8Mn (weight percent) is smelted on a resistance furnace. The alloy is prepared by using 99.99% pure magnesium and 99.99% pure zinc, and manganese (Mn) in the alloy is added in the form of chemically pure MnCl. Melting is carried out at a volume ratio of 99 to 99.5% CO 2 and 0.5~1%SF 6 (Sulfur hexafluoride) protective atmosphere, the melting temperature is controlled at 700-800 °C. Then add 5-15 μm hydroxyapatite powder according to the weight percentage of 10% and 15% respectively, and adopt the method of mechanical stirring to uniformly mix it with the magnesium alloy liquid. The alloy is then cast into a metal mold and then extruded into a rod-shaped material under certain conditions.

Embodiment 3

[0036] Firstly, Mg-2.0Zn-2.0Ca (weight percent) is smelted on a resistance furnace. The alloy is fused with 99.99% pure magnesium, 99.99% pure zinc and metallic calcium. Melting is carried out at a volume ratio of 99 to 99.5% CO 2 and 0.5~1%SF 6 (Sulfur hexafluoride) protective atmosphere, the melting temperature is controlled at 700-800 °C. Then add 5-20 μm Mg-substituted hydroxyapatite powder (Mg-substituted hydroxyapatite, containing 1.2% Mg, by weight) according to 5% and 15% by weight respectively, and uniformly mix it with the magnesium alloy liquid by means of mechanical stirring. The alloy is then cast into a metal mold and then extruded into a rod-shaped material under certain conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com