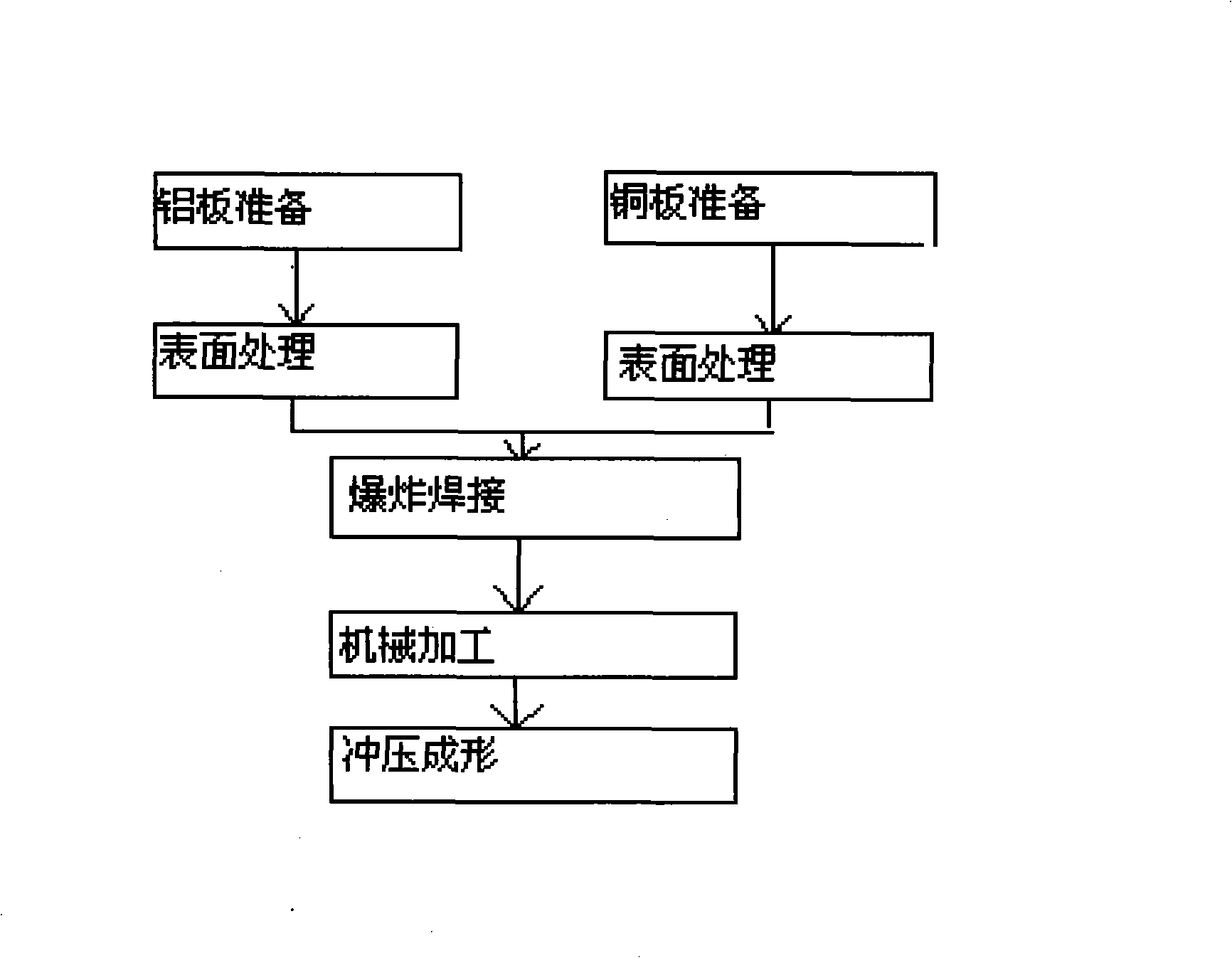

Method for producing aluminum-copper duplex metal compound weldment

A manufacturing method and bimetal technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of non-composite delamination of the interface, low interface bonding strength, and poor composite quality, so as to achieve uniform bonding strength and improve The effect of high efficiency and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

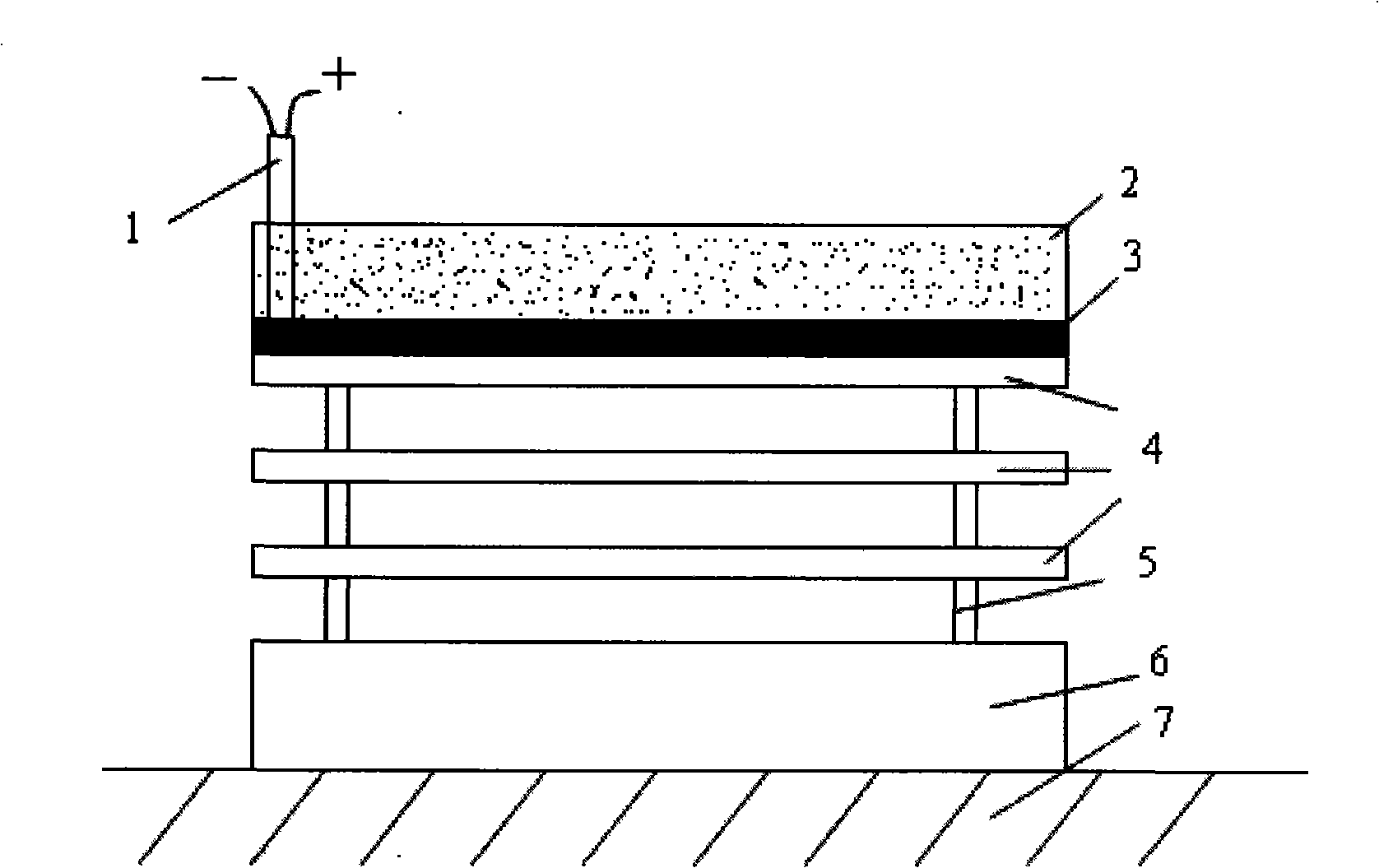

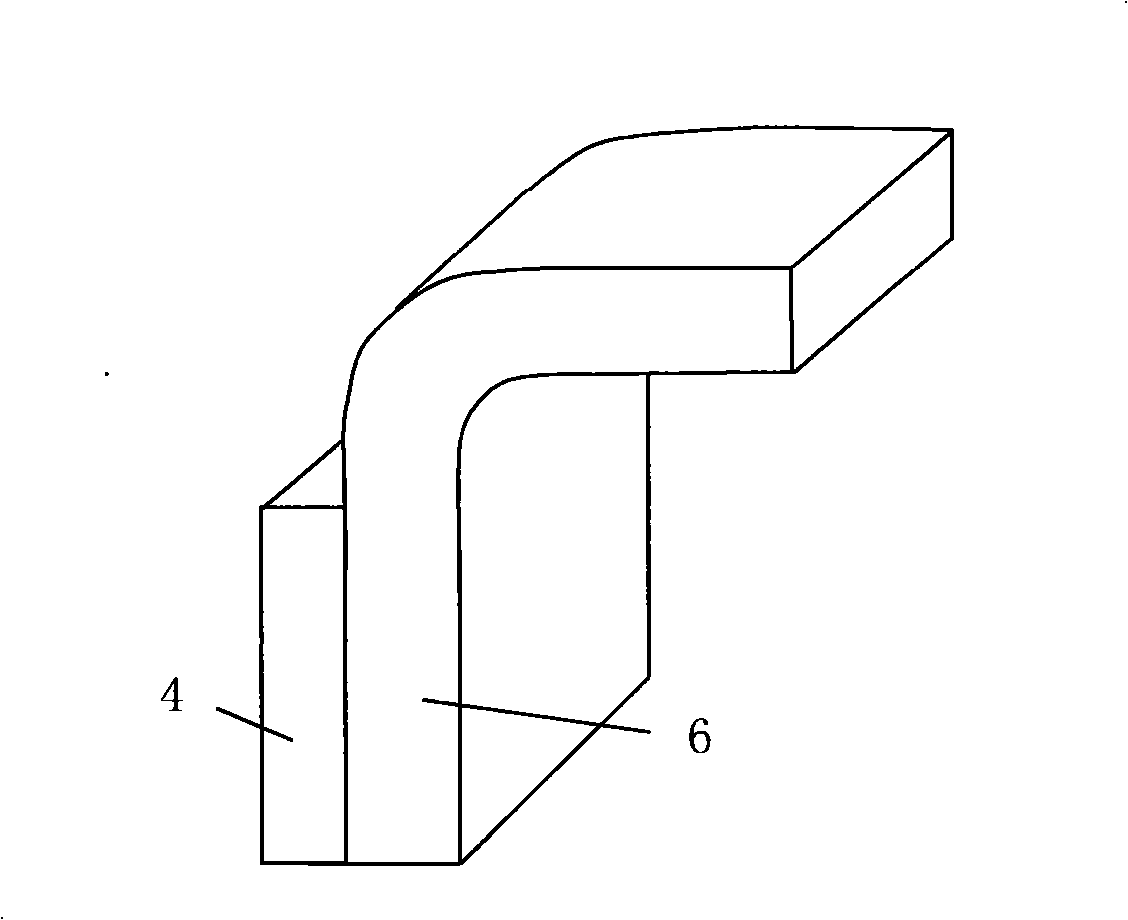

Embodiment approach 1

[0036] Manufacture the aluminum-copper bimetal composite material with two layers of clad aluminum plate, select the grade of the base copper plate as T2, the size is 20×1200×3000mm, the clad aluminum plate is divided into 2 layers, the grade is pure aluminum 1060, and the size is from top to bottom respectively 8×1250×3100mm and 4×1250×3100mm, the heights of the supports (5) between the two layers of aluminum plates (4) and between the base copper plate (6) are 5mm and 3mm respectively, and the base copper plate (6) is placed On the sand foundation (7); paste anti-rust oil paper on the surface of the first layer of aluminum plate as the buffer protection layer (3), use ammonium nitrate explosives (2), directly lay on the surface of the buffer protection layer (3), charge the charge per unit area The amount is 2.8g / cm 2 , using No. 8 industrial electric detonator (1) to detonate, the aluminum-copper bimetallic composite material obtained by explosive welding has good composite...

Embodiment approach 2

[0038] Manufacture the aluminum-copper bimetallic composite material with 5 layers of clad aluminum plate, choose the grade of the base copper plate as T1, the size is 40×1200×3000mm, the clad aluminum plate is divided into 5 layers, the grade is pure aluminum 1070, the size is from top to bottom respectively 10×1250×3100mm, 10×1250×3100mm, 10×1250×3100mm, 10×1250×3100mm and 4×1250×3100mm, the support between the clad aluminum plate (4) and the base copper plate (6) The height of the object (5) is 7mm, 7mm, 7mm, 7mm, and 3mm from top to bottom, and the base copper plate (6) is placed on the sand foundation (7); paste the anti-rust oil paper buffer protection layer on the surface of the first layer of aluminum plate ( 3), using ammonium nitrate explosive (2), directly placed on the surface of the buffer protection layer, the charge per unit area is 4.8g / cm 2 , using No. 8 industrial electric detonator (1) to detonate, the aluminum-copper bimetallic composite material obtained b...

Embodiment approach 3

[0040] Manufacture the aluminum alloy-copper bimetallic composite material with 3 layers of clad aluminum plate, select the base copper plate as T1, the size is 24×1000×3000mm, the clad aluminum plate is layered, the grade is aluminum alloy 3A21, the size is from top to bottom respectively 10×1050×3100mm, 10×1050×3100mm and 4×1050×3100mm, the height of the support between the clad aluminum alloy plates and between the base copper plate is 7mm, 7mm, 3mm from top to bottom, the base copper plate (6) Place on the sand foundation (7); Paste the anti-rust oil paper buffer protection layer on the surface of the first layer of aluminum plate, use ammonium nitrate explosives, directly lay on the surface of the buffer protection layer, the charge per unit area is 3.6g / cm 2, using No. 8 industrial electric detonator to detonate, the aluminum alloy-copper bimetallic composite material obtained by explosive welding has good composite quality, the interface shear strength is ≥ 80Mpa, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com