High dispersibility water-soluble acroid resin prepared by continuous bulk polymerization, preparation and use thereon in printing ink

An acrylic resin, bulk polymerization technology, applied in the application field of ink, can solve the problems of high molecular weight distribution index of resin, can not effectively solve the problem of reaction heat emission, high ink viscosity, etc. Fast, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

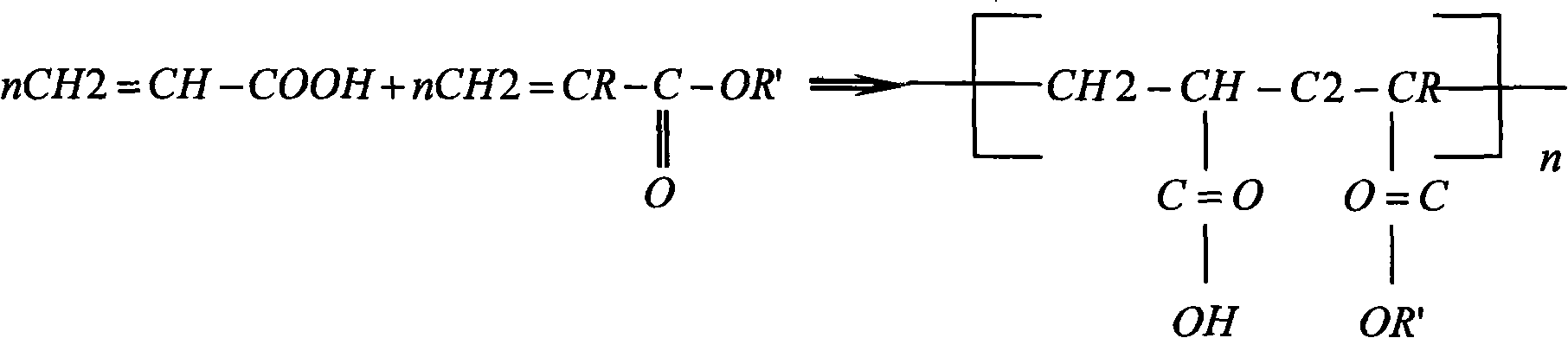

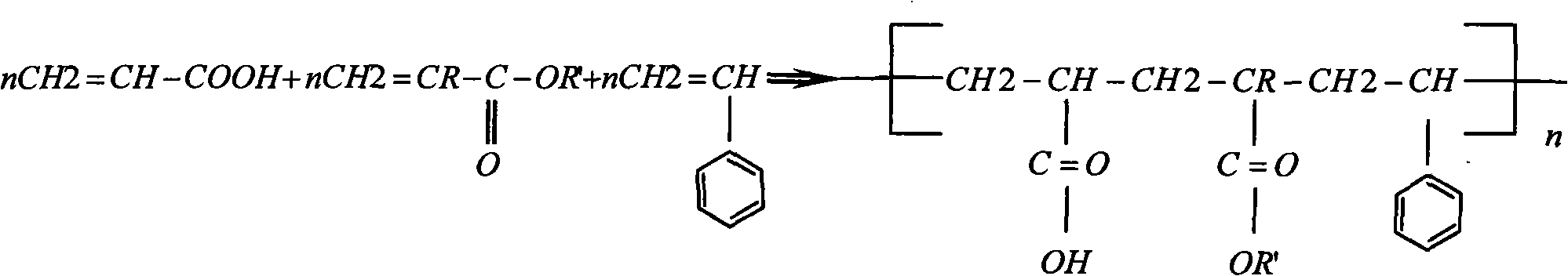

Method used

Image

Examples

Embodiment Construction

[0050] Add 30 grams of acrylic acid, 68.5 grams of styrene, 1 gram of α-methylstyrene dimer, and 0.5 gram of tert-butyl hydroperoxide in the head tank according to the formula, turn on the high-pressure pump, and pump the reaction mixture into the reactor. Under the conditions of high temperature and high pressure at 250°C, 2.5Mpa, and a holding time of 30 minutes, the material is continuously fed and discharged, and then the discharged melt enters the devolatilization tank for devolatilization, and then is molded by an extruder to obtain the finished product.

[0051] Performance comparison with similar products

[0052] 30% water-soluble resin aqueous solution comparison:

[0053] Table five 30% resin aqueous solution

[0054] Johnson 678

600cps

Soluryl 70

500cps

This patented product

700cps

[0055] With the 30% aqueous solution of water-soluble resin prepared in table five, the blue base ink is prepared according to the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com