Energy-saving type low voltage set aluminum cell

An aluminum electrolytic cell and low-voltage technology, which is applied in the field of energy-saving low-voltage setting aluminum electrolytic cell, can solve the problems of staying in the theoretical discussion and laboratory test stage, the cell voltage setting is too high, and the output of electrolytic aluminum decreases. Achieve the effects of stable electrolysis process operation, reduced production power consumption, and balanced technical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

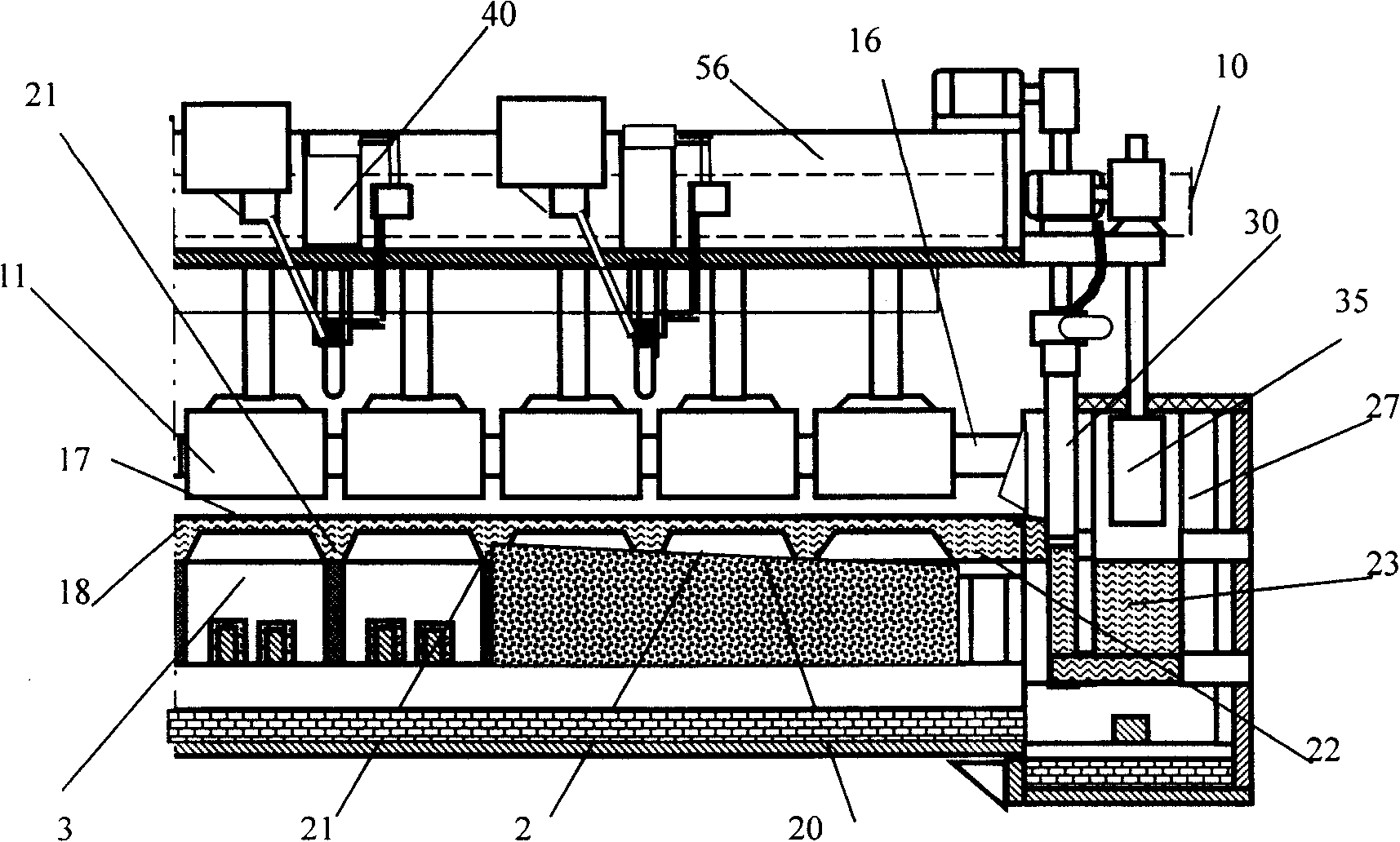

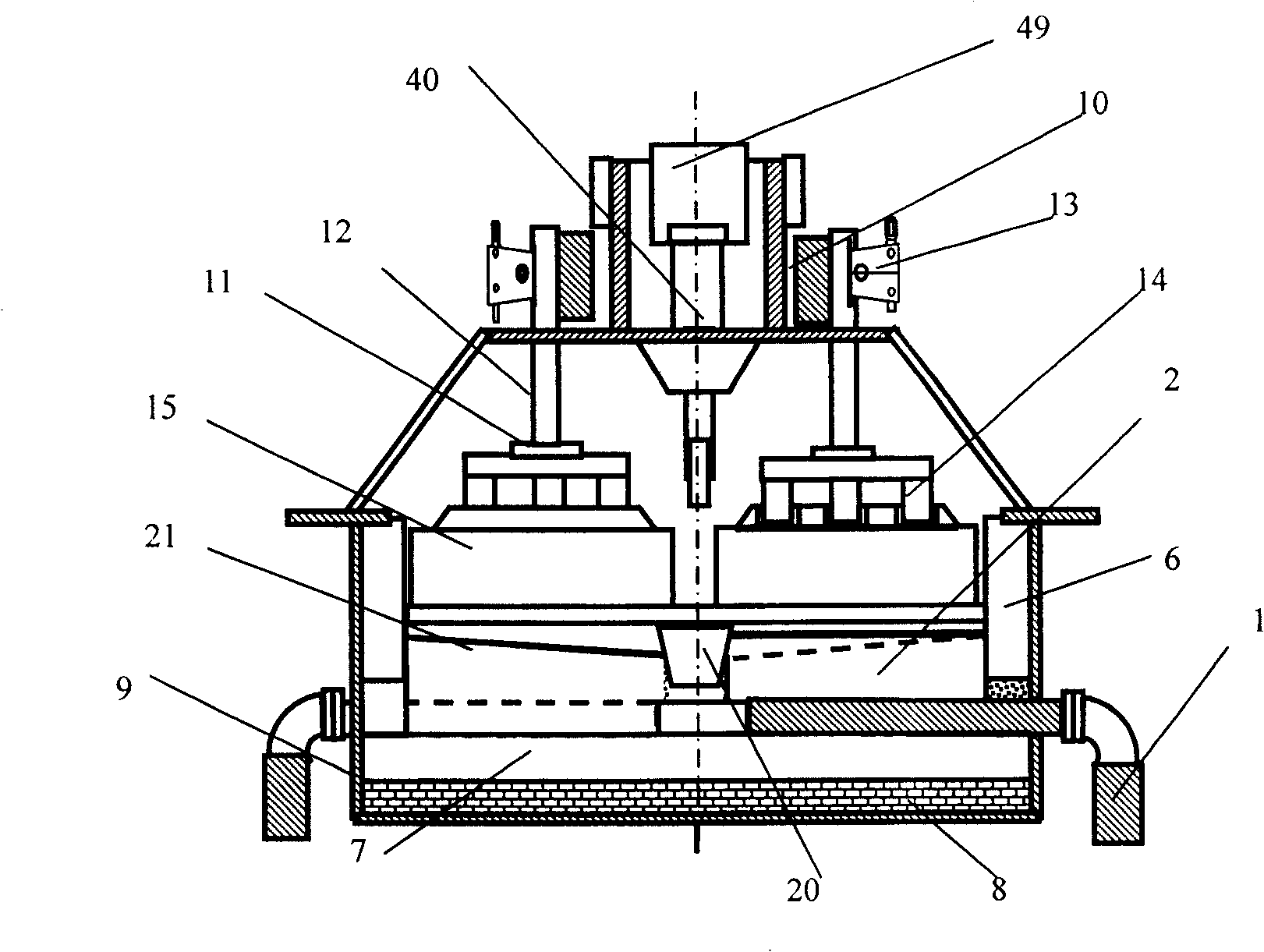

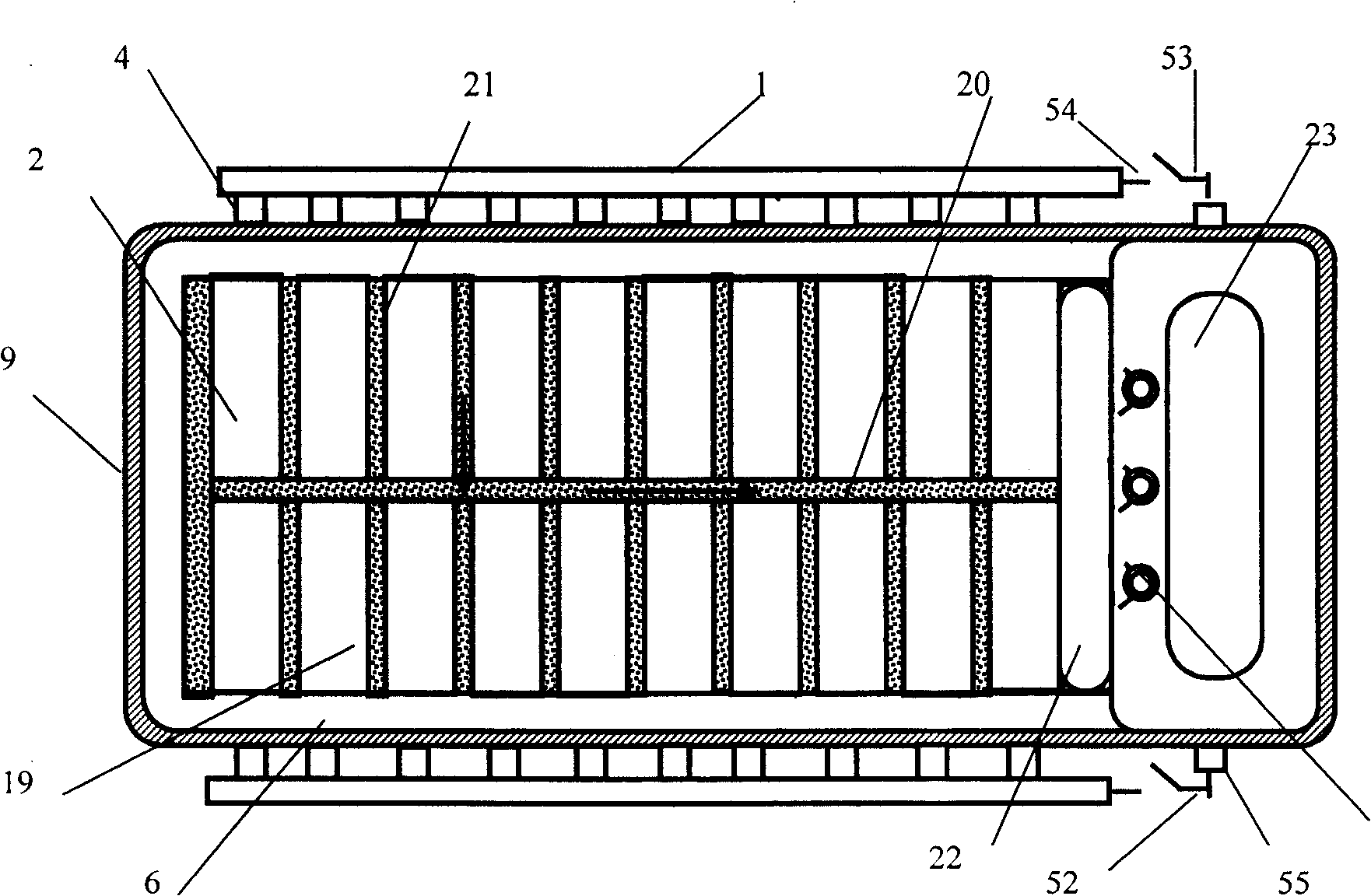

[0035] Such as figure 1 , figure 2 , image 3 As shown in , the energy-saving low-voltage electrolytic cathode lining is built. In the steel shell 9, a cathode lining 2 is constructed on the insulation layer 8 and the anti-leakage material layer 7. The cathode lining 2 is made of cathode carbon Block 3, cathode steel rod 4, tamping paste 5, side carbon 6 are built by masonry, the upper surface of the cathode lining 2 is rammed with a layer of graphite carbon titanium boride coating 19, and the cathode lining 2 is close to the aluminum end side The end portion is configured with an aluminum storage tank 27, and a diversion coagulation tank 22 is configured between the end of the cathode lining 2 side and the aluminum storage tank 27.

[0036] Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the main liquid aluminum diversion groove 20 and the aluminum liquid branch diversion groove 21 are constructed at the position of the upper part of the cathode liner 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com