Apparatus for micro heat pipe vacuum pumping liquid injection

A technology of vacuum pumping and micro heat pipe, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of difficult to guarantee the precision of liquid injection and vacuum degree, complicated procedures and low precision, and achieve simple structure, liquid injection and other problems. Precise, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

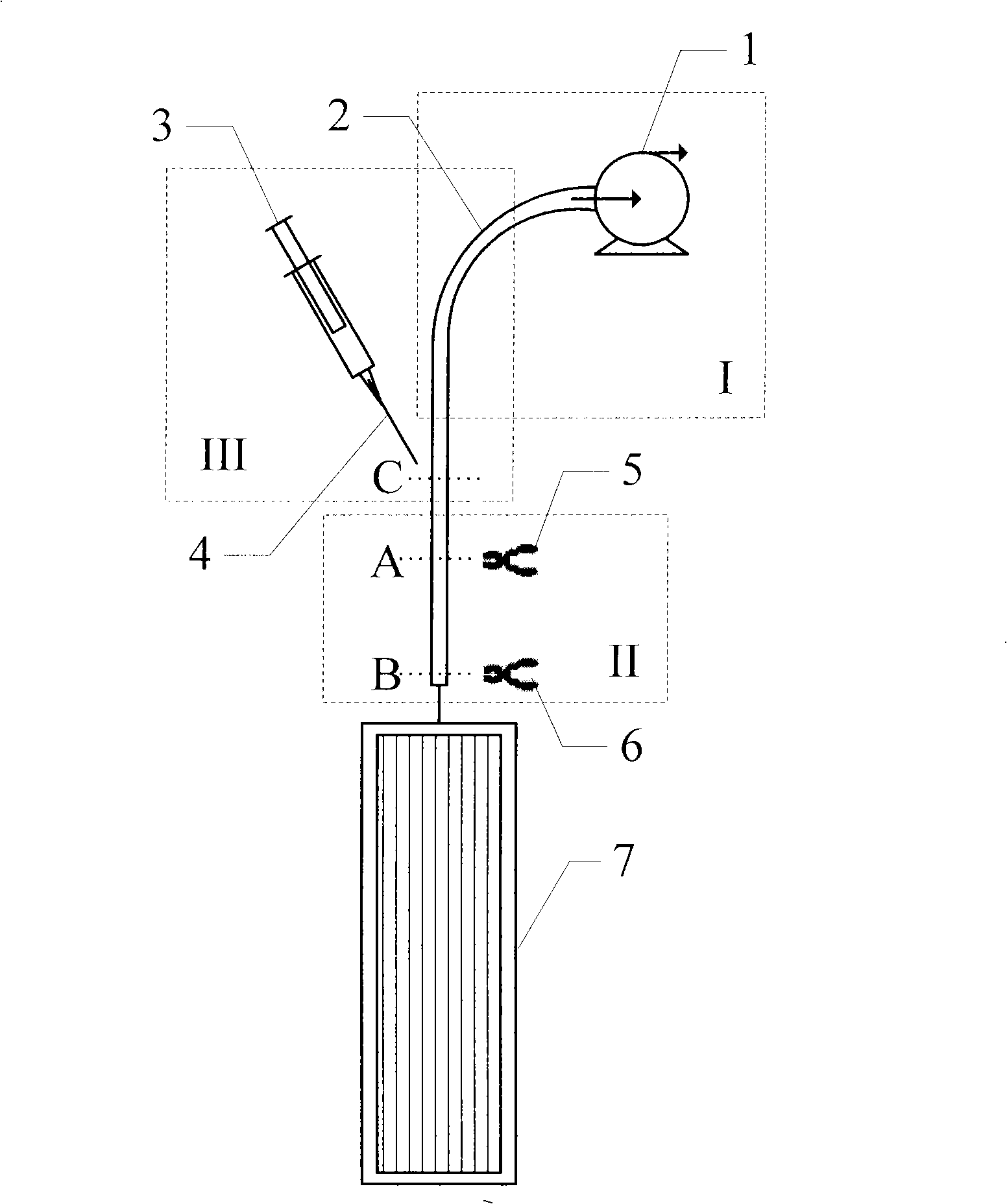

[0020] combine figure 1 , the present embodiment is made up of vacuumizing part I, trace liquid calibration part II, liquid injection part III; said vacuumizing part I is made up of vacuum pump 1 and capillary hose 2, and one end of capillary hose 2 is connected with vacuum pump 1, and another One end is sealed and connected to the liquid injection hole of the micro-heat pipe 7 through a micro-needle; the micro-liquid calibration part II is composed of a capillary tube 2, a micro-clamp 5, and a micro-clamp 6, and the liquid injection volume is calibrated through the length of the capillary tube 2. The micro clamp 5 and the micro clamp 6 are used to clamp the hose to block the liquid or gas in the tube; the liquid injection part III is composed of a capillary tube 2, a liquid injection needle 4 and a syringe 3, and the liquid passes through the syring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com