Method for manufacturing micromechanical components

A micro-mechanical component and micro-mechanical technology, applied in the manufacture of micro-structure devices, electrical components, micro-structure technology, etc., can solve problems such as limiting the thickness of structural layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

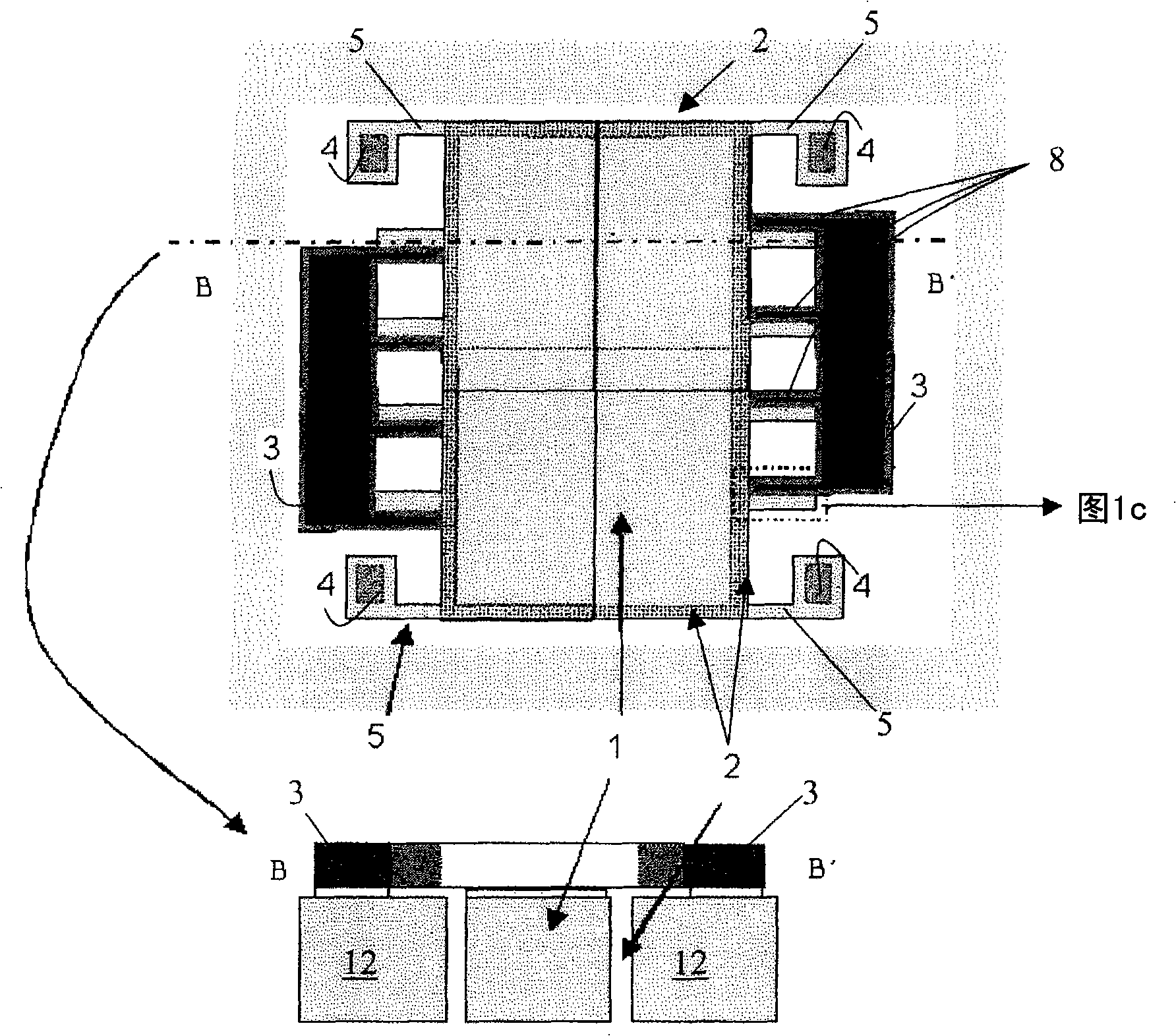

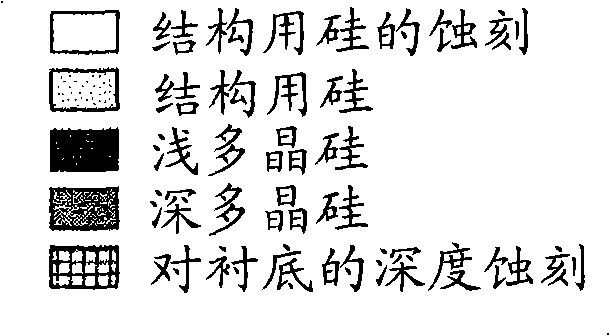

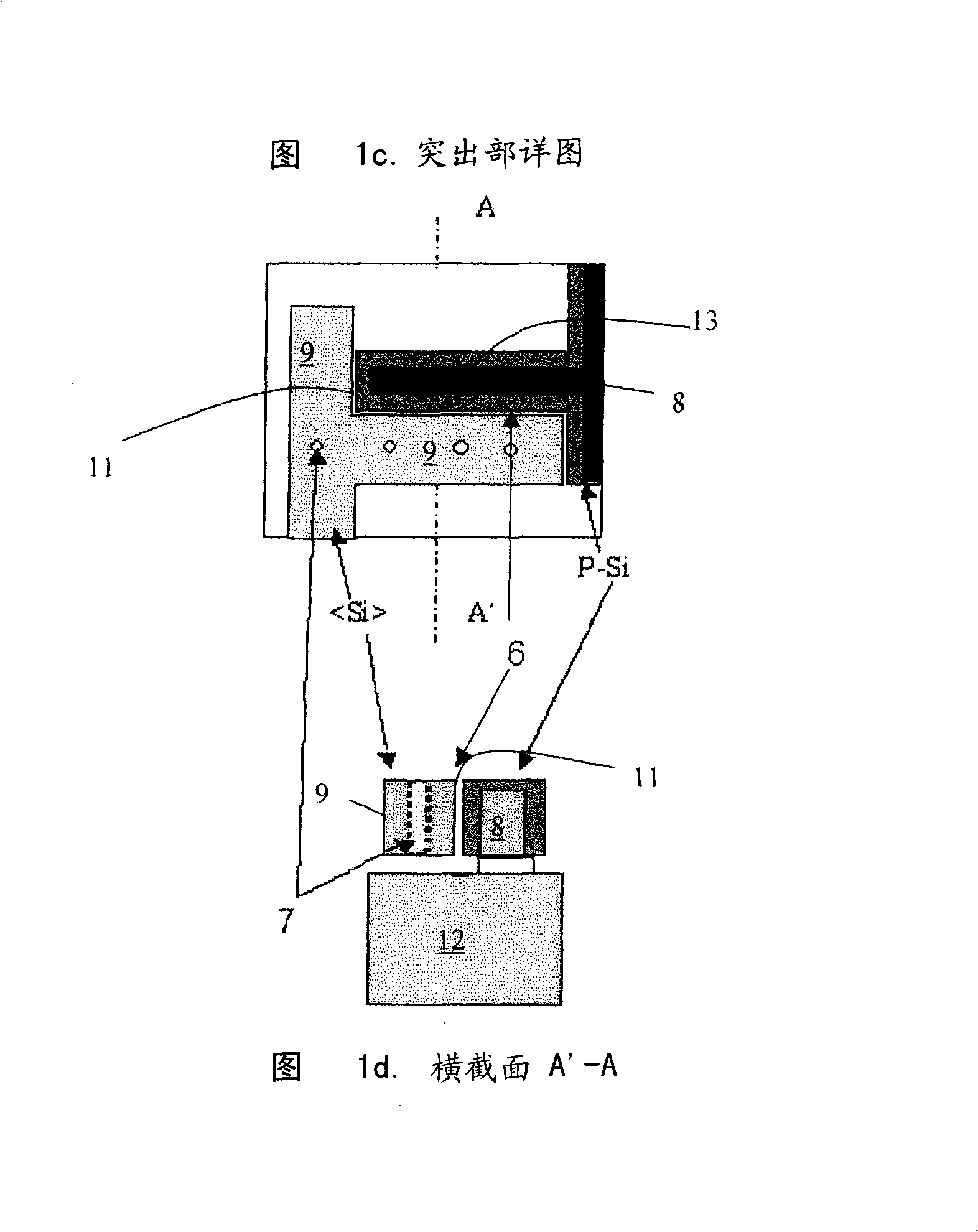

[0050] In FIG. 1 , a movable structure 1 made of monocrystalline silicon “floats” on four anchors 4 to which it is attached by means of suspension springs 5 . A groove 2 is provided around the movable structure 1 , which groove ensures the mobility of said structure by separating the movable structure 1 from the substrate 12 . Detection holes 7 are also provided in single crystal silicon for release etching. In monocrystalline silicon, there are at least two protrusions 9, while a corresponding number of electrode protrusions 8 are arranged relative to them. Between the protrusion 9 and the electrode protrusion 8 of the monocrystalline silicon, a narrow gap 6 is etched, which is formed by a longitudinal groove 11 and a transverse groove 13 , and forms a gap in which the junction capacitance is formed by the protrusions 8 , 9 . The protrusions give the electrode structure a comb-like profile when viewed from above.

[0051] figure 2 The individual steps (steps 1-7) of a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com