Method for preparing liquid ethylene based polysilazane resin by UV initiated vinyl silazane rapid polymerization

The technology of vinyl polysilazane and vinyl silazane is applied in the synthesis field of liquid vinyl polysilazane, and can solve the problems of high reaction temperature, slow reaction rate, difficult reaction control, etc., and avoid thermal polymerization. Effect

Inactive Publication Date: 2010-12-01

NORTHWESTERN POLYTECHNICAL UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

One is the addition reaction of Si-H, N-H and vinyl double bonds on the molecular chain at high temperature (generally 280-300°C). Although the synthesis rate of this polymerization reaction is relatively fast (tens of Minutes), but due to the high reaction temperature, the reaction is difficult to control; the other is to use a platinum catalyst to perform thermal polymerization at 50-90°C. Although this type of reaction avoids the disadvantages of high thermal polymerization temperature and difficult control of the reaction, However, there are still defects such as slow reaction rate and long synthesis cycle, and the reaction time generally needs more than 8 hours

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

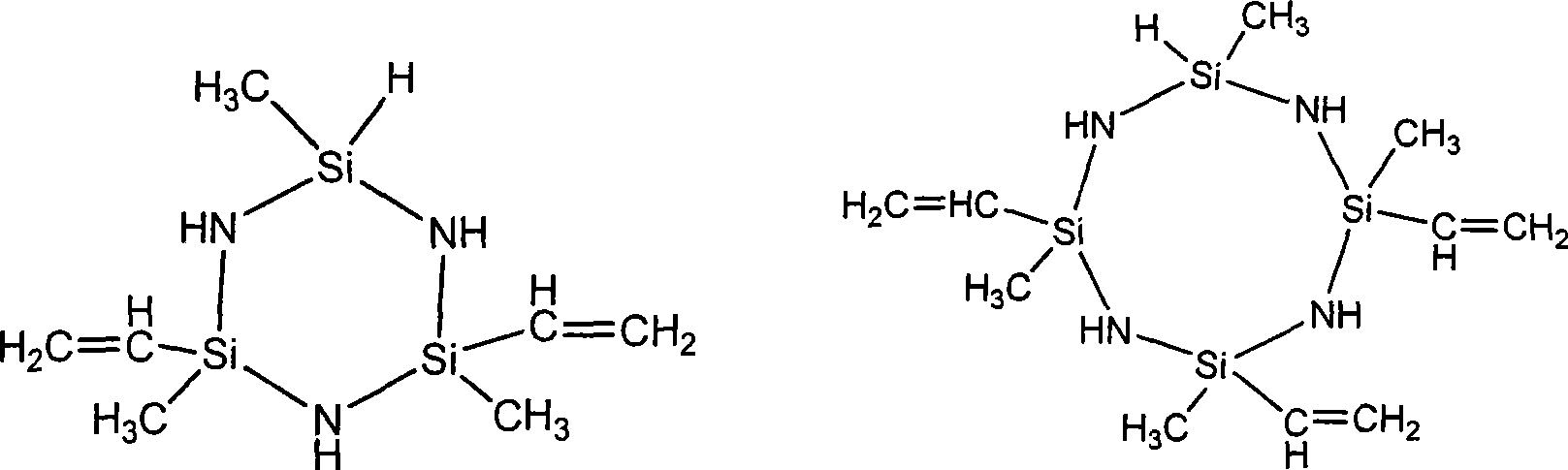

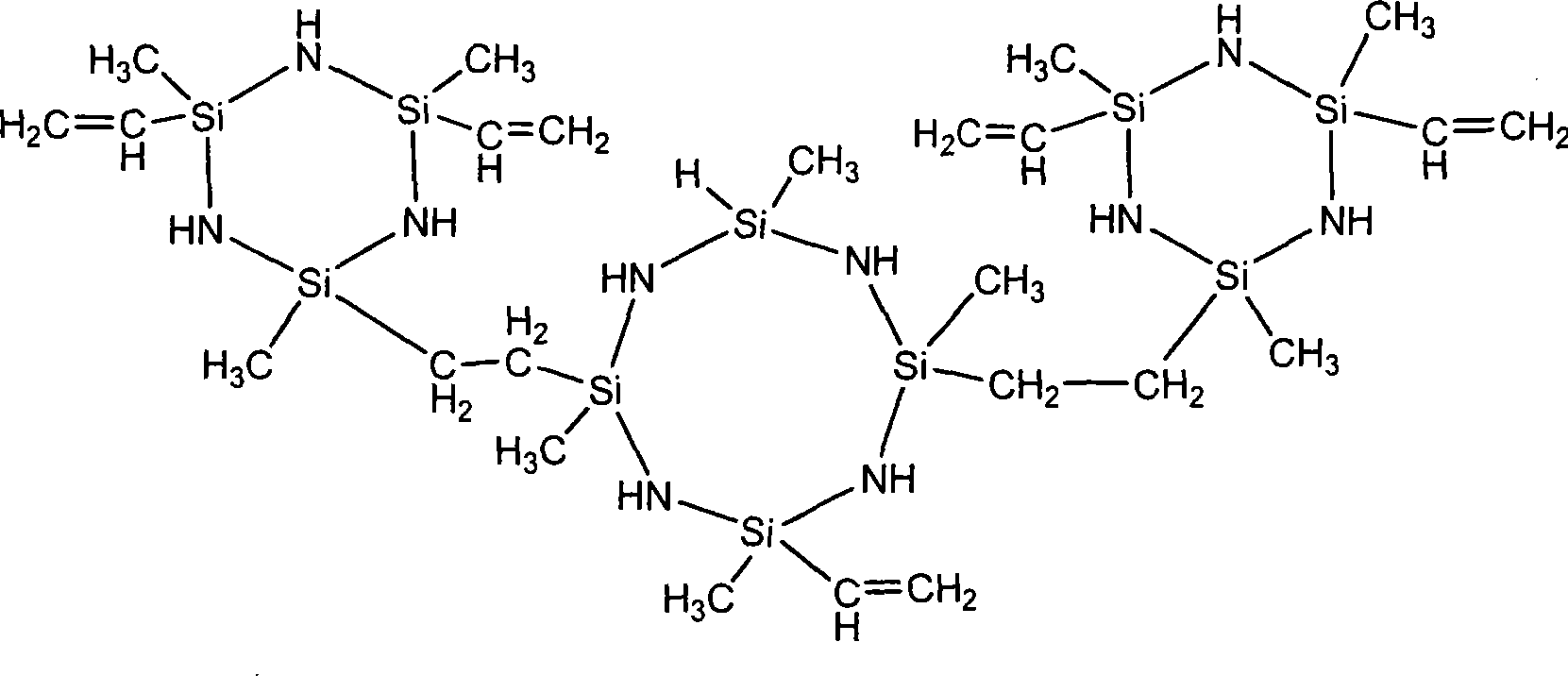

The invention relates to a method for preparing liquid vinyl poly-silazane resin by fast polymerization of vinyl poly-silazane initiated by UV light, and the technique thereof is characterized by comprising the following steps: methyl vinyl dichlorsilane, methyl hydrogen dichlorsilane and an organic solvent are added into a flask, and then put the flask in a water-ice bath for evenly mixing; ammonia gas is introduced for reaction; after the introduction of the ammonia gas is stopped, the ice-water bath is removed and after the reaction is restored to room temperature, resultant is filtered; then filtrate is heated and decompressed for removing normal hexane, and when no solvent is generated, heating is stopped, vacuum-pumping is carried out and temperature is reduced to the room temperature; a diacetyl acetone platinum catalyst is added and then dissolved by stirring; an ultraviolet lamp is turned on for irradiation and finally a transparency liquid of colorless to light yellow is obtained. The vinyl poly-silazane resin prepared by the method of the invention has the advantages that: the yield thereof can achieve 44-50 percent of the input amount of chlorsilane, viscosity is within 300-2000mPa question mark s, and the analysis of gel permeation chromatography (GPC) shows that the M<w> of the synthesized vinyl poly-silazane resin can be up to 4200, and the molecular weight dispersion coefficient thereof is within 1.6-4.0.

Description

Method for preparing liquid vinyl polysilazane resin by rapid polymerization of vinyl silazane induced by ultraviolet light technical field The invention relates to a method for preparing liquid vinyl polysilazane resin through rapid polymerization of vinyl silazane induced by ultraviolet light, which belongs to the synthesis method of liquid vinyl polysilazane. Background technique Silicon nitride and silicon carbide ceramic materials can be prepared by pyrolysis conversion method using polymer ceramic precursors containing silicon, nitrogen and (or) carbon elements. The preparation of ceramic materials by this method has the advantages of adjustable composition of silazane (carbon) alkane precursors, and can be shaped by general polymer processing methods. It has broad application prospects in the fields of aerospace thermal protection, ceramic fiber, and connection of ceramic structural parts. Currently used polysilazane resins containing active groups (such as vinyl,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G77/62

Inventor 陈立新宋家乐

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com