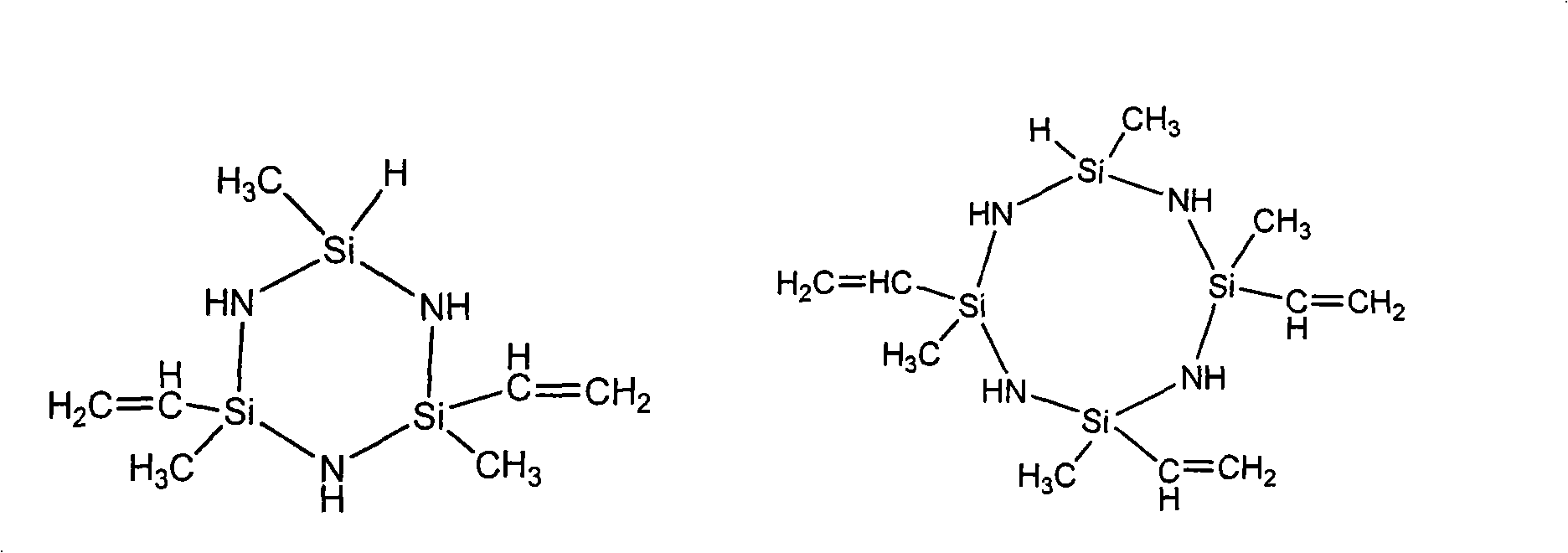

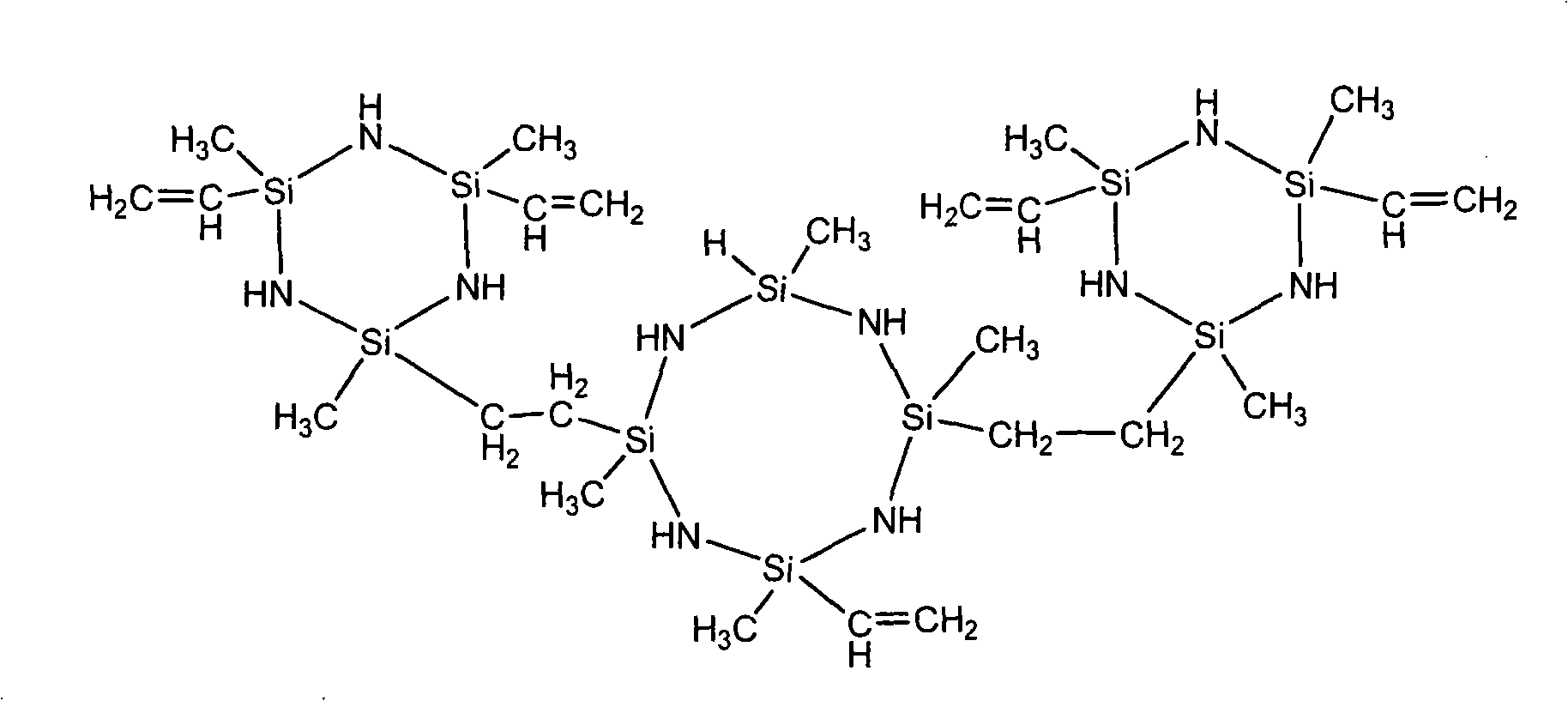

Method for preparing liquid ethylene based polysilazane resin by UV initiated vinyl silazane rapid polymerization

A vinyl polysilazane and vinyl silazane technology, which is applied to the synthesis field of liquid vinyl polysilazane, can solve the problems of high reaction temperature, difficult reaction control, slow reaction rate and the like, and avoids thermal polymerization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Formula 1: 0.5 mol (70.5 g) of methylvinyldichlorosilane, 0.15 mol (17.3 g) of methylhydrogendichlorosilane, 500.0 g of organic solvent n-hexane, and 0.04 g of platinum diacetylacetonate.

[0023] Synthesis process: Add the raw materials methylvinyldichlorosilane, methylhydrogendichlorosilane and n-hexane according to the ratio into a 1000mL four-neck flask equipped with a thermometer and a stirrer, put it in an ice-water bath to cool to -5°C, and start The mixer mixes the ingredients well. Then feed ammonia gas at a flow rate of 15-20L / h, and react for 2.5 hours. After the ammonia gas flow was stopped, the ice bath was removed. After the reaction returned to room temperature, the product was filtered to remove the generated salt. The filtrate was heated (not exceeding 90°C) and n-hexane was removed under reduced pressure, and the solvent was collected for recycling. When no solvent comes out, stop heating and vacuuming, lower to room temperature, add platinum diacetyl...

Embodiment 2

[0027] Formula 2: 0.5 mol (70.5 g) of methylvinyldichlorosilane, 0.2 mol (23.0 g) of methylhydrogendichlorosilane, 600.0 g of n-hexane, and 0.04 g of platinum diacetylacetonate.

[0028] Synthesis process: Add the raw materials methylvinyldichlorosilane, methylhydrogendichlorosilane and n-hexane according to the ratio into a 1000mL four-necked flask equipped with a thermometer and a stirrer, put it in an ice-water bath to cool to 0°C, and start stirring Mix the ingredients evenly. Then feed ammonia gas at a flow rate of 15-20L / h, and react for 2.5 hours. After the ammonia gas flow was stopped, the ice bath was removed. After the reaction returned to room temperature, the product was filtered to remove the generated salt. The filtrate was heated (not exceeding 90°C) and n-hexane was removed under reduced pressure, and the solvent was collected for recycling. When no solvent comes out, stop heating and vacuuming, lower to room temperature, add platinum diacetylacetonate catalys...

Embodiment 3

[0033] Formula 3: 0.5 mol (70.5 g) of methylvinyldichlorosilane, 0.15 mol (17.3 g) of methylhydrogendichlorosilane, 600.0 g of cyclohexane, and 0.04 g of platinum diacetylacetonate.

[0034] Synthesis process: Add the raw materials methylvinyldichlorosilane, methylhydrogendichlorosilane and n-hexane according to the ratio into a 1000mL four-necked flask equipped with a thermometer and a stirrer, put it in an ice-water bath to cool to 2°C, and start stirring Mix the ingredients evenly. Then feed ammonia gas at a flow rate of 15-20L / h, and react for 2.5 hours. After the ammonia gas flow was stopped, the ice bath was removed. After the reaction returned to room temperature, the product was filtered to remove the generated salt. The filtrate was heated (not exceeding 90°C) and n-hexane was removed under reduced pressure, and the solvent was collected for recycling. When no solvent comes out, stop heating and vacuumize, lower to room temperature, add platinum diacetylacetonate cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com