Method for eliminating residual stress in steel

A residual stress and pulse current technology, applied in the direction of improving process efficiency, can solve problems such as affecting the structure of materials, and achieve the effects of simple and convenient operation, elimination of residual stress and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

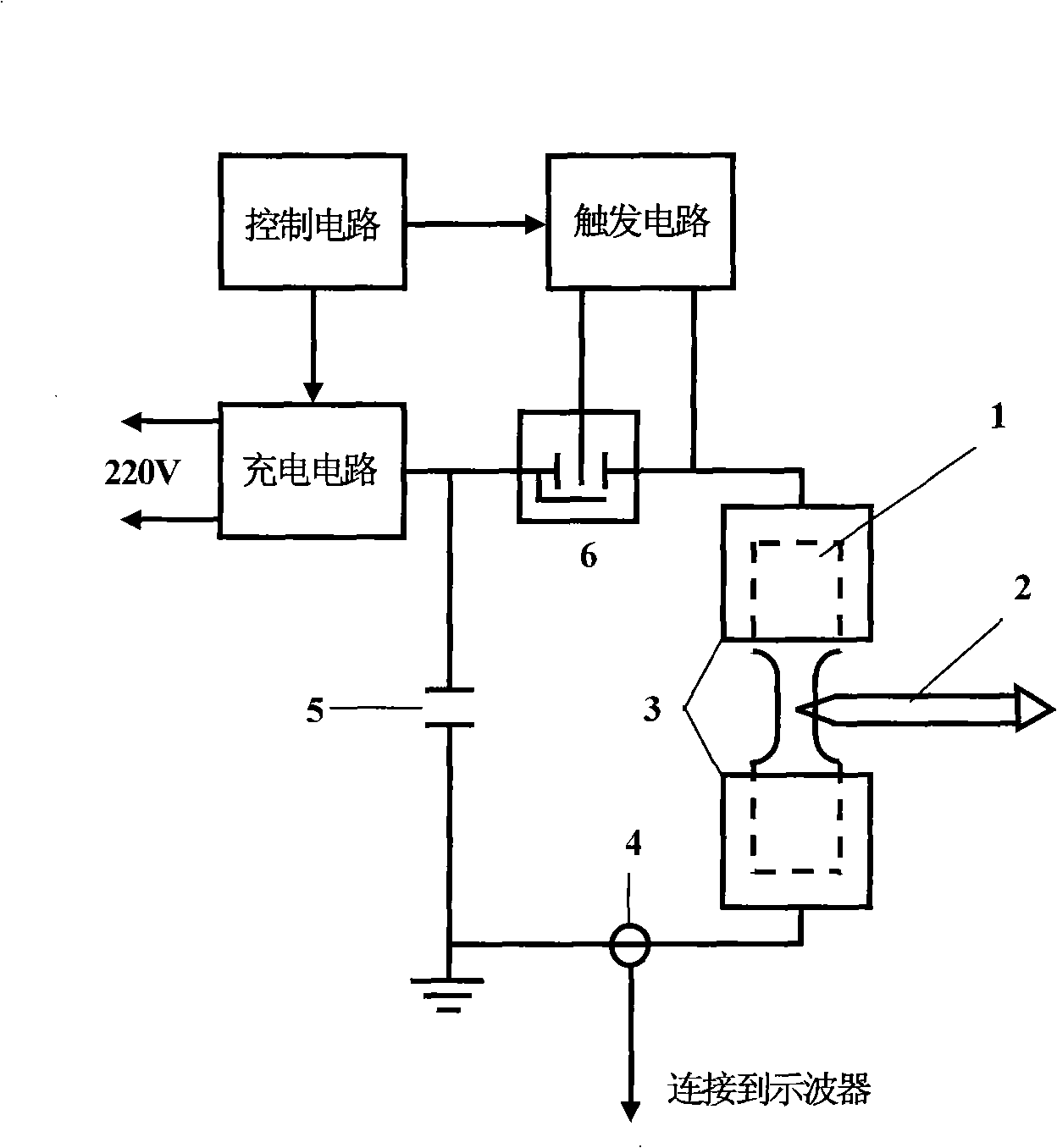

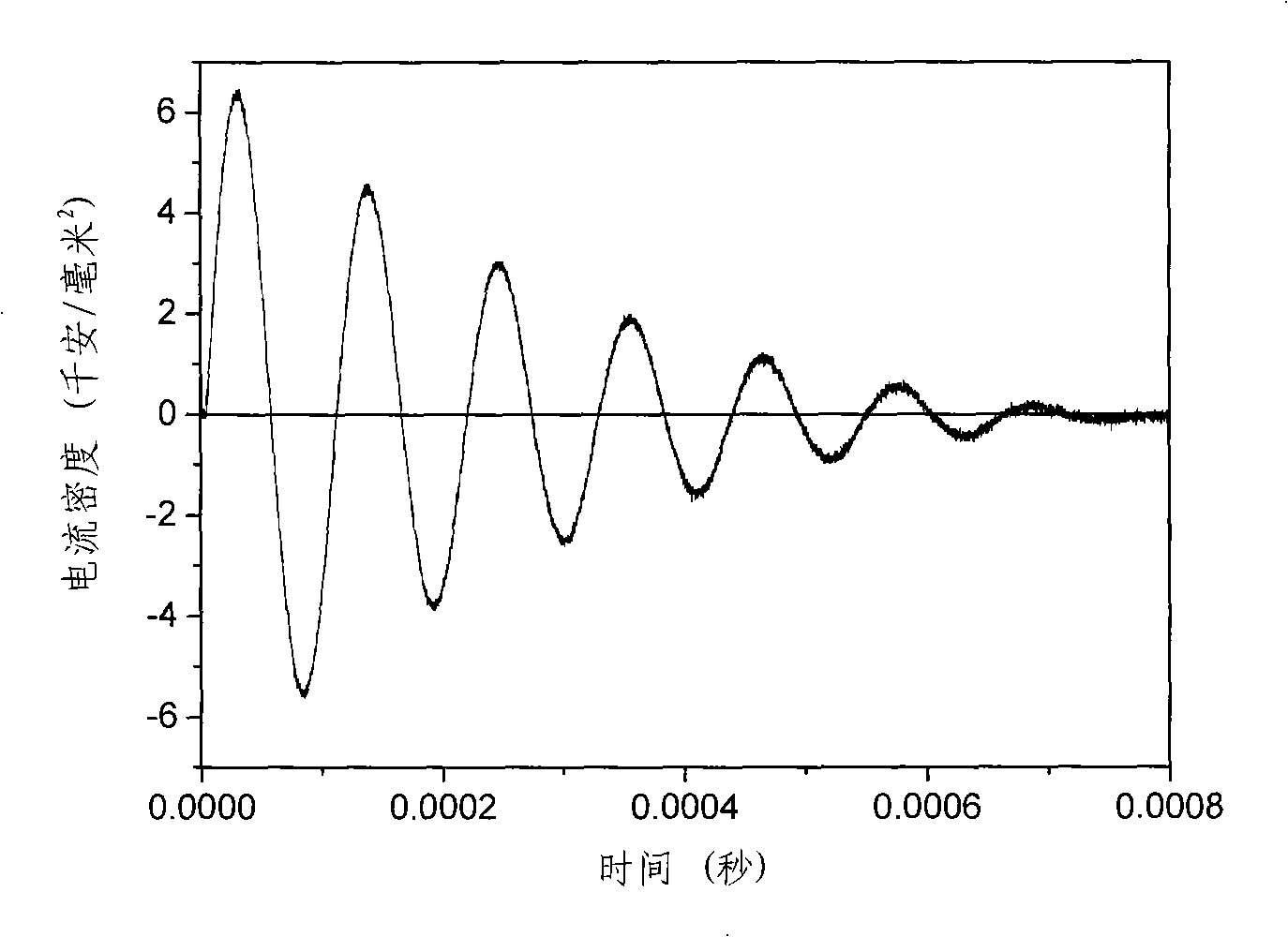

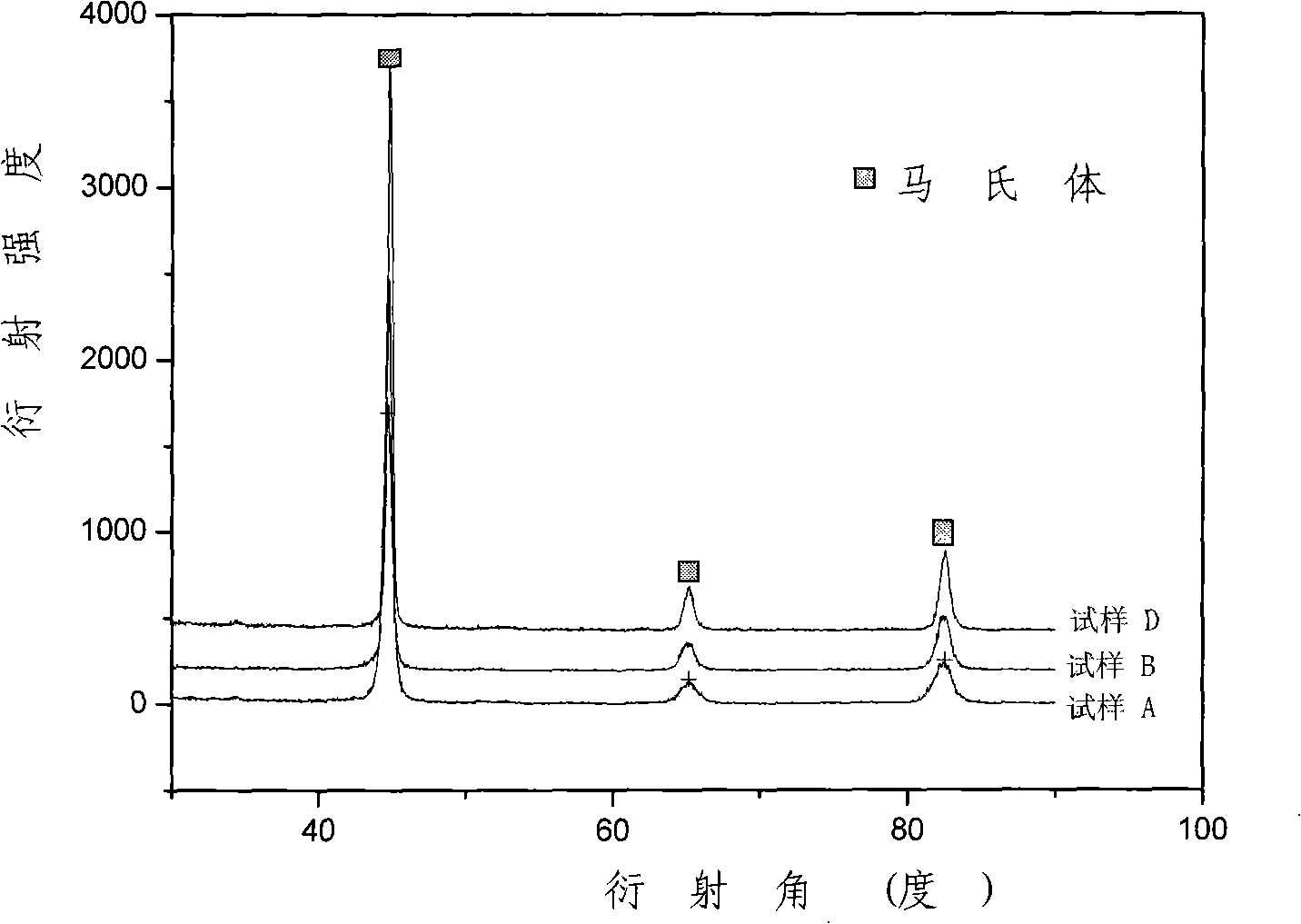

[0017] The steel used is 40Cr steel, and the chemical composition (mass fraction, %) of the steel is: C 0.38, Mn 0.69, Si 0.33, Cr 0.93. figure 1 It is a schematic diagram of the device (discharge circuit) of the pulse current processing process (this device is a known technology). It consists of a pulse current generator and an oscilloscope. The pulse current generator includes a current detection coil 4, a capacitor bank 5, a discharge switch 6, a control circuit, a trigger circuit, a charging circuit, etc. The control circuit is used to control the charging circuit and the trigger circuit respectively. Opening and closing; when working, the control circuit sends an instruction to the charging circuit. After the capacitor bank 5 is charged, the control circuit sends an instruction to the trigger circuit to close the discharge switch. The capacitor bank 5 discharges to generate a pulse current, and the sample 1 is processed. The current detection coil 4 is externally connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com