Coaxial reverse rotating electric generator

A generator, coaxial technology, applied in wind turbine components, engines, wind power generation and other directions, can solve the problems of low power generation efficiency of wind turbines, and achieve the effects of expanding effective surface area, good stability and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

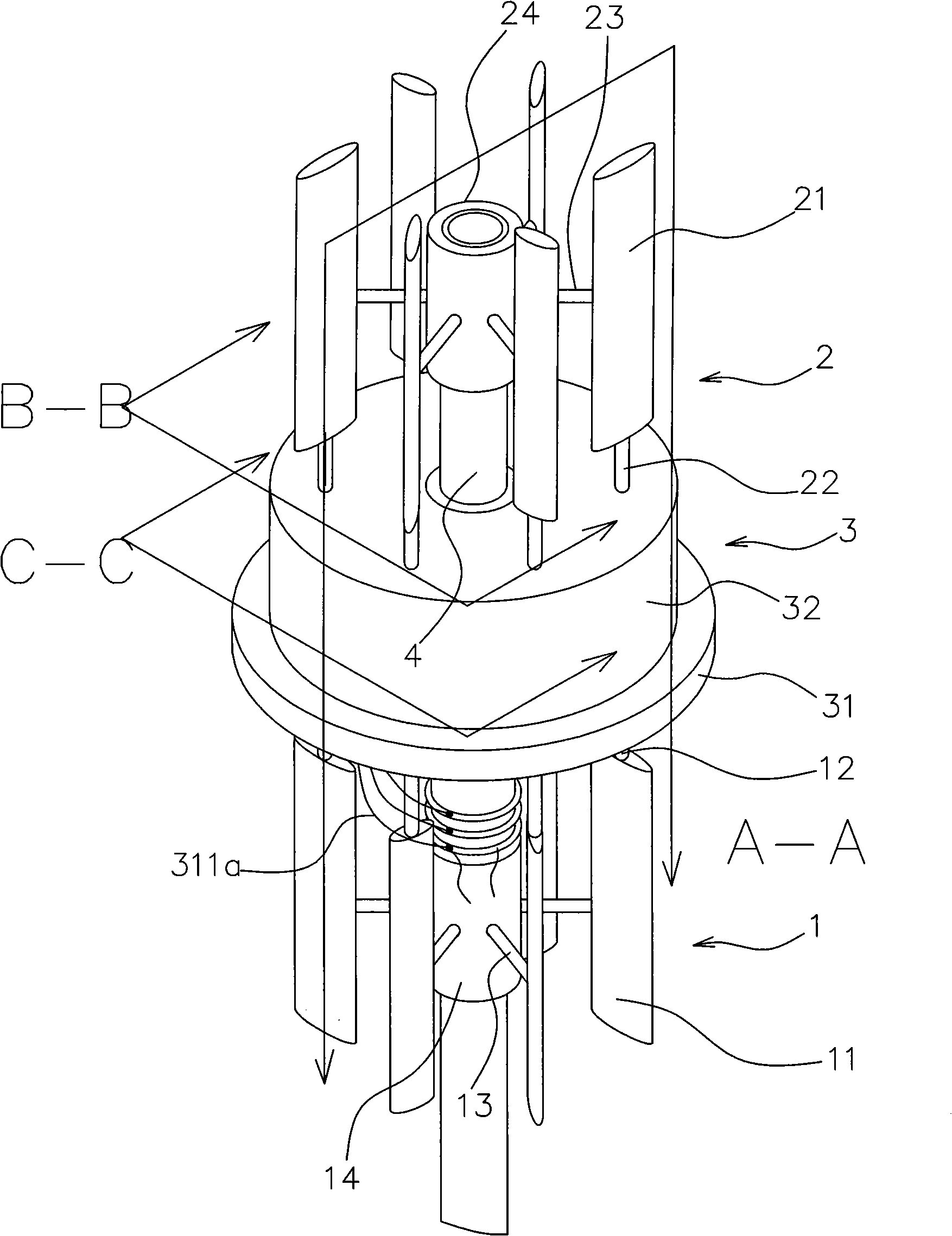

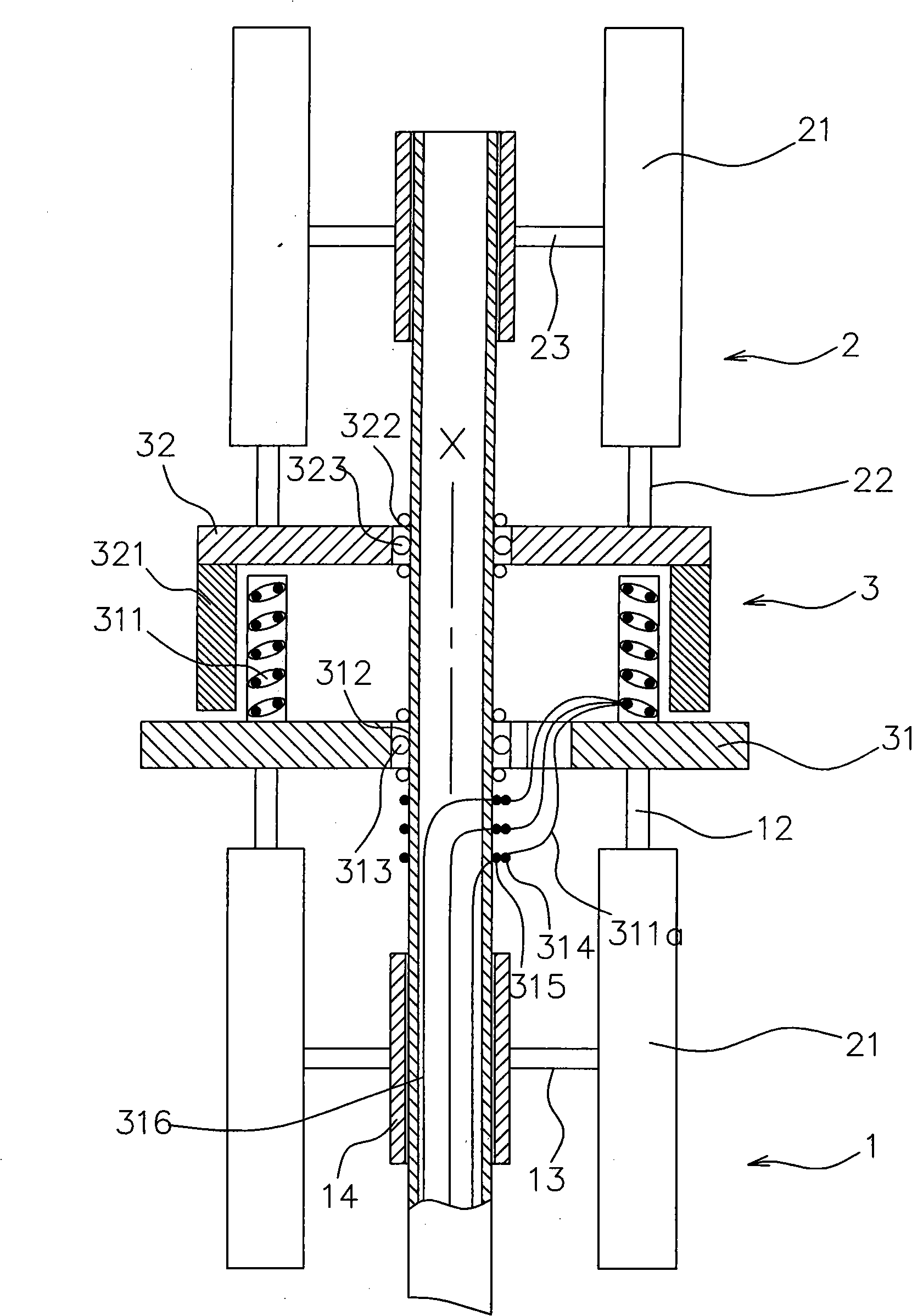

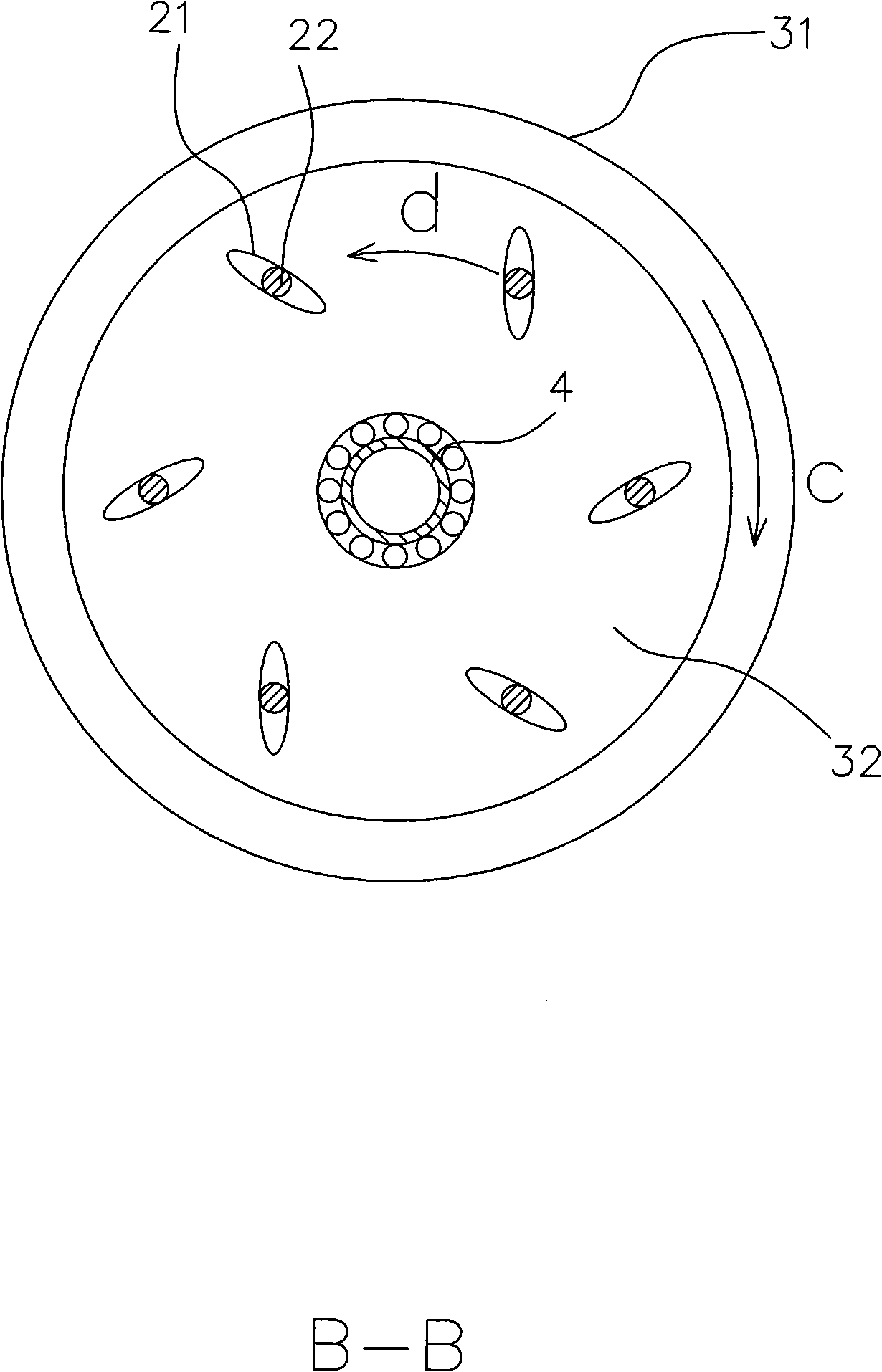

[0029] see figure 1 , 2 , the exploded view of the first embodiment of the present invention and the A-A combined sectional schematic diagram of the first embodiment, wherein the first embodiment of the present invention includes two drive assemblies 1, 2, a motor 3, and a shaft 4, and the two drives Components 1 and 2 are respectively provided with several blades 11, 21, and the respective blades 11, 21 are respectively provided with engaging columns 12, 22 to be fixedly connected to the two rotating seats 31, 32 described later, and the several blades 11, 21 are respectively approximately parallel to Axial (shaft 4 direction), and arranged in a ring shape, and the blades 11, 21 are set at different angles, so that the blades 11, 21 can act in opposite directions when the blades 11, 21 are impacted by the external medium, and the blades 11, 21 21. Connecting rods 13, 23 are arranged at appropriate places in the center to join the sleeves 14, 24, and the sleeves 14, 24 fit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com