System for measuring temperature of coal gas flow bed gasification reactor and method for measuring temperature of coal gas flow bed gasification reactor using the same

A gasification reactor and temperature measurement technology, applied in the field of coal gasification, can solve the problem that the safety status of the gasification reactor cannot be grasped, and the surface temperature of the gasification reactor cannot be accurately grasped from time to time. Problems such as dangerous operation of bed gasification reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The direct temperature measuring part of the invention is used to measure the temperature of the gas flow-bed gasification reactor.

[0090] Use Henan Yima coal, water, highly polymerized sodium naphthalenesulfonate, and sodium carbonate to make a slurry with a hydrocarbon-containing substance concentration of about 65% by weight, and their proportions are 61.5% and 38% by weight of the total material. %, 0.3%, 0.2%, the flow rate is 68613.5kg / h, after being boosted to 7.8MPa by the high-pressure slurry pump, it is sent into the gasification reactor of the gas flow bed, and the pure oxygen oxidizing agent with a concentration of 99.6% (volume) is introduced. The incomplete combustion reaction is carried out at an operating pressure of 6.5MPa and a reaction temperature of 1390°C to obtain CO+H 2 Dry synthesis gas with a content of 78.8% (dry basis volume).

[0091] Wherein, the gas entrained bed gasification reactor adopts the double platinum-rhodium thermocouple of the...

Embodiment 2

[0095] The indirect temperature measuring part of the invention is used to measure the temperature of the gas flow-bed gasification reactor.

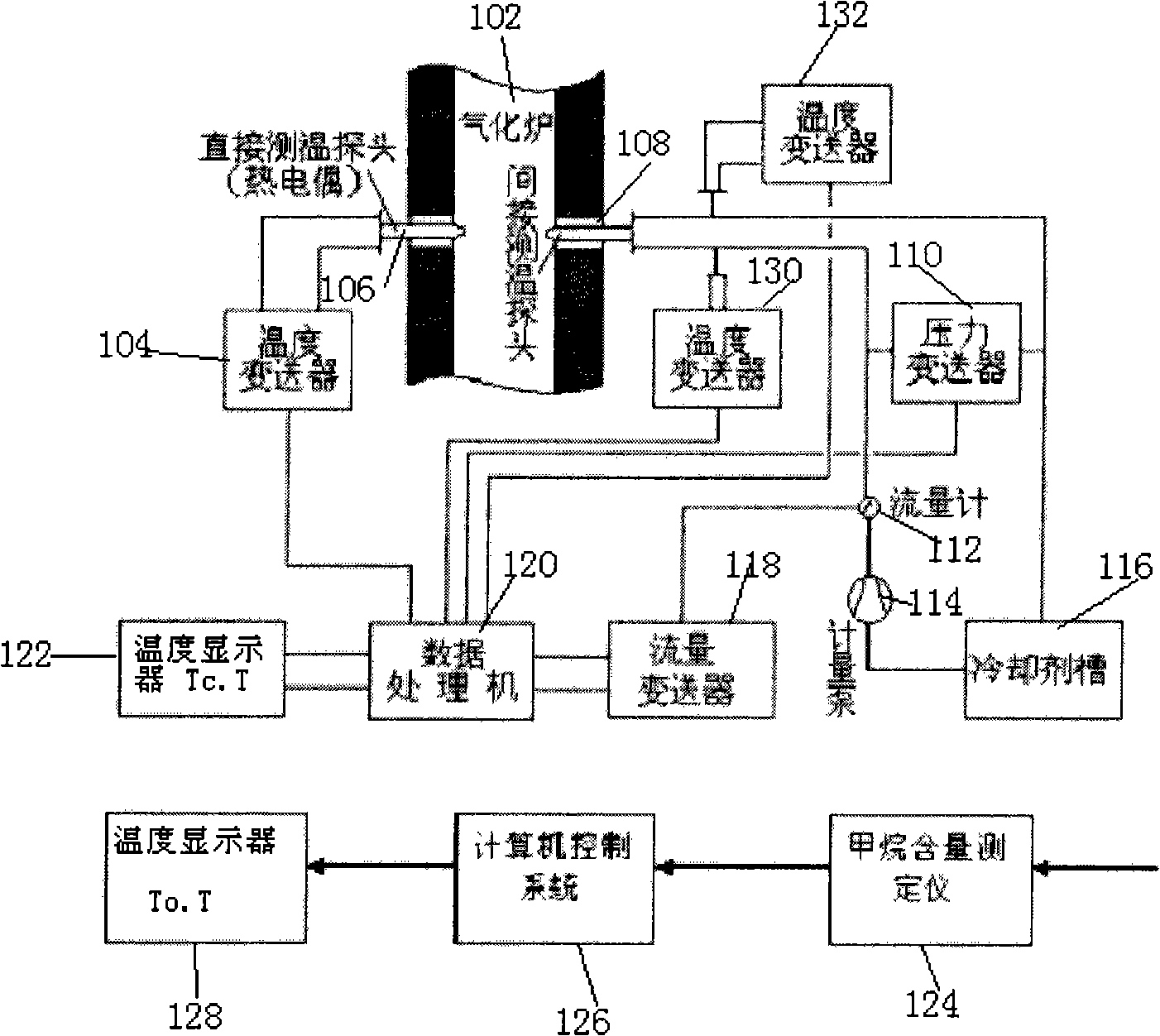

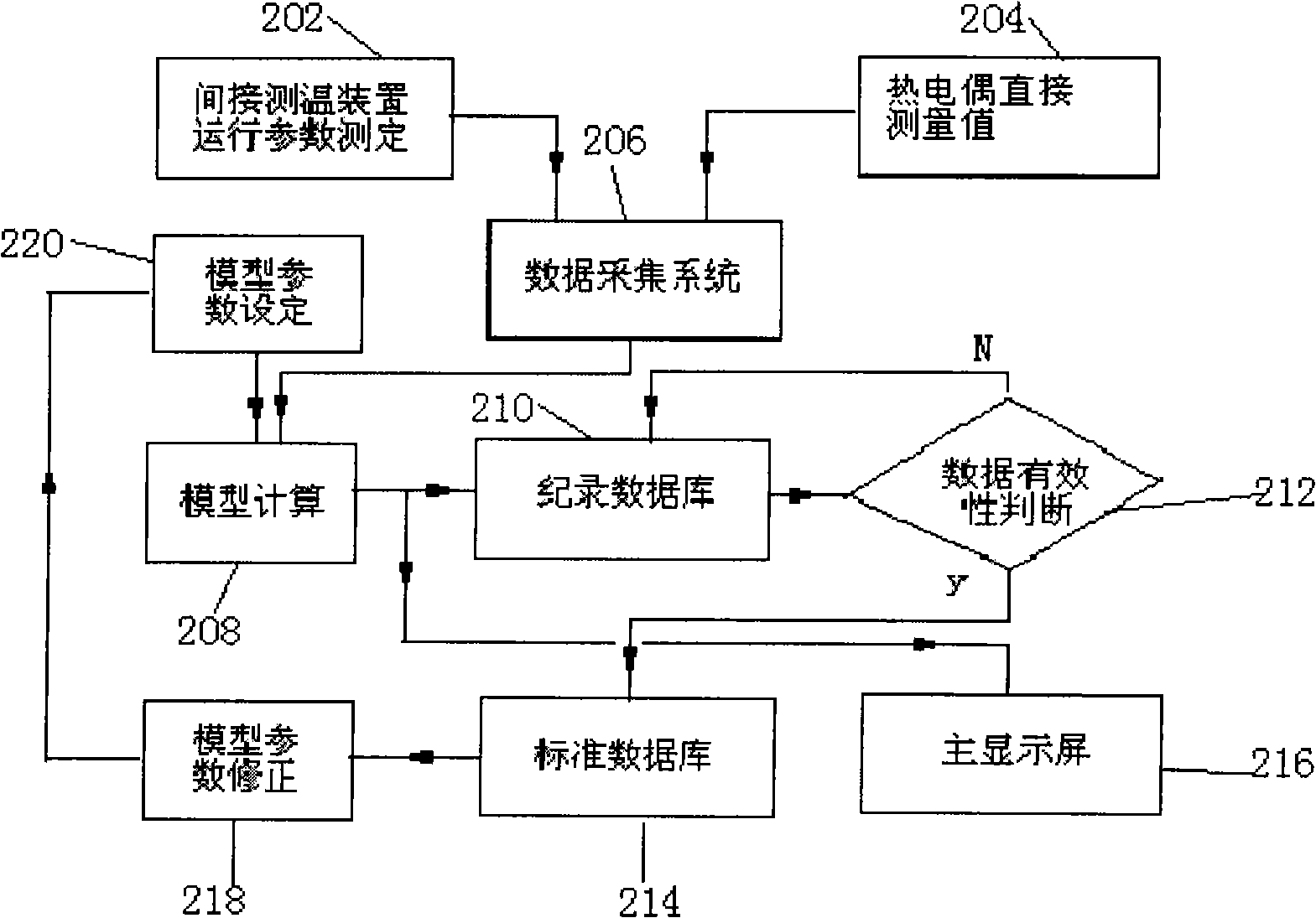

[0096] The crude synthesis gas was prepared in the same coal entrained bed gasification reactor as in Example 1 and under the same reaction conditions. Adopt the double platinum-rhodium thermocouple identical with embodiment 1 to measure the temperature of described gas entrained bed gasification reactor directly and the indirect temperature measurement part of the present invention, as figure 1 shown. By passing cooling water into the indirect temperature measuring probe 108, the temperature transmitter 130 and the temperature transmitter 132 sold by Hangzhou Tiankang Instrument Co., Ltd. under the trade name temperature transmitter are used to measure the temperature when the cooling water enters and exits the probe respectively. Temperature, and then through the flow meter 112 sold by Hangzhou Tiankang Instrument Co., Ltd. under the...

Embodiment 3

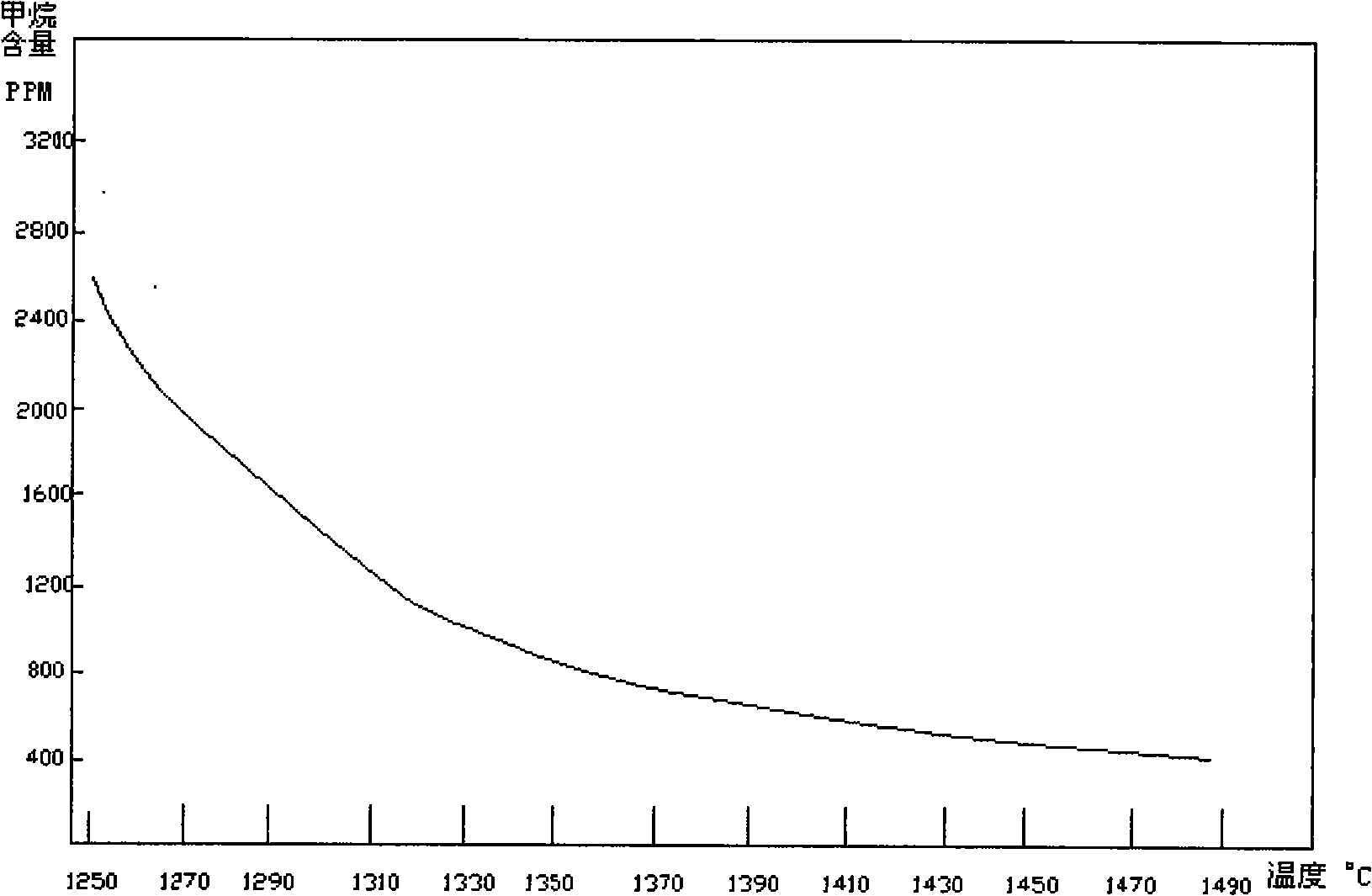

[0106] The temperature of the entrained gasification reactor was measured by methane content thermometry.

[0107] The crude synthesis gas was prepared in the same coal entrained bed gasification reactor as in Example 1 and under the same reaction conditions. The temperature of the gas entrained bed gasification reactor was measured by using the same double platinum-rhodium thermocouple direct temperature measurement part as in Example 1 and the methane content temperature measurement part of the present invention. The methane content in the crude synthesis gas was measured using a methane content measuring instrument sold by Zhuhai Saisite Instrument Equipment Co., Ltd. under the trade name non-dispersive infrared detector. Measured the temperature of this gas entrained bed gasification reactor, its methane content and gasification reactor temperature value are listed in the following table 4:

[0108] Table 4 Comparison value of methane content and gasification reactor temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com