White light LED for improving facula and encapsulation method thereof

A packaging method and white light technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that white light LEDs cannot meet the market demand of high-end applications, poor output beam quality, and uneven light spots, etc., to improve the color zone achievement rate, Improve the shipment rate and solve the effect of uneven spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

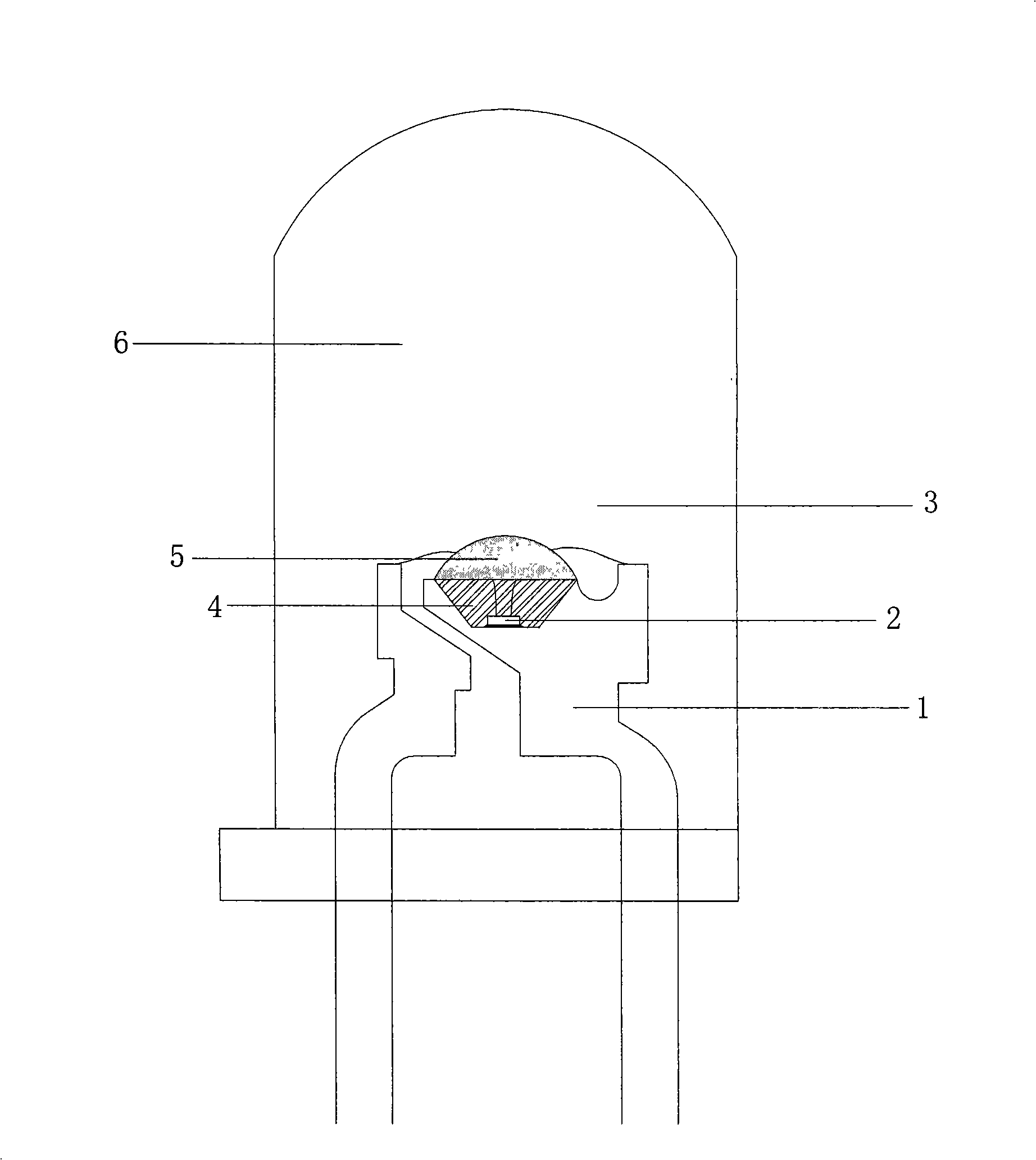

[0029] see figure 1 , a white light LED with improved light spot, the LED blue light chip 2 is fixed in the concave metal receiving seat 1, the positive and negative electrodes of the LED blue light chip are respectively connected with the positive and negative pins in the concave metal receiving seat through the wire 3, A fluorescent glue layer 4 is arranged on the LED blue light chip, and a whitening glue layer 5 is arranged outside the fluorescent glue layer, and the concave metal socket 1, the LED blue light chip 2, the fluorescent glue layer 4 and the whitening glue layer 5 are packaged by epoxy resin 6 Among them; the fluorescent adhesive layer is composed of phosphor powder and epoxy resin; the whitening adhesive layer is composed of white particles and epoxy resin.

[0030] The fluorescent glue layer can also be composed of fluorescent powder and silica gel, or composed of fluorescent powder and silicone resin.

[0031] The whitening glue layer can also be composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com