Control method for correcting phase of brushless DC motor without position sensor

A brushed DC motor, phase correction technology, applied in current controllers, electronic commutators, etc., can solve problems such as delay, out-of-step or stall, and inaccurate signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

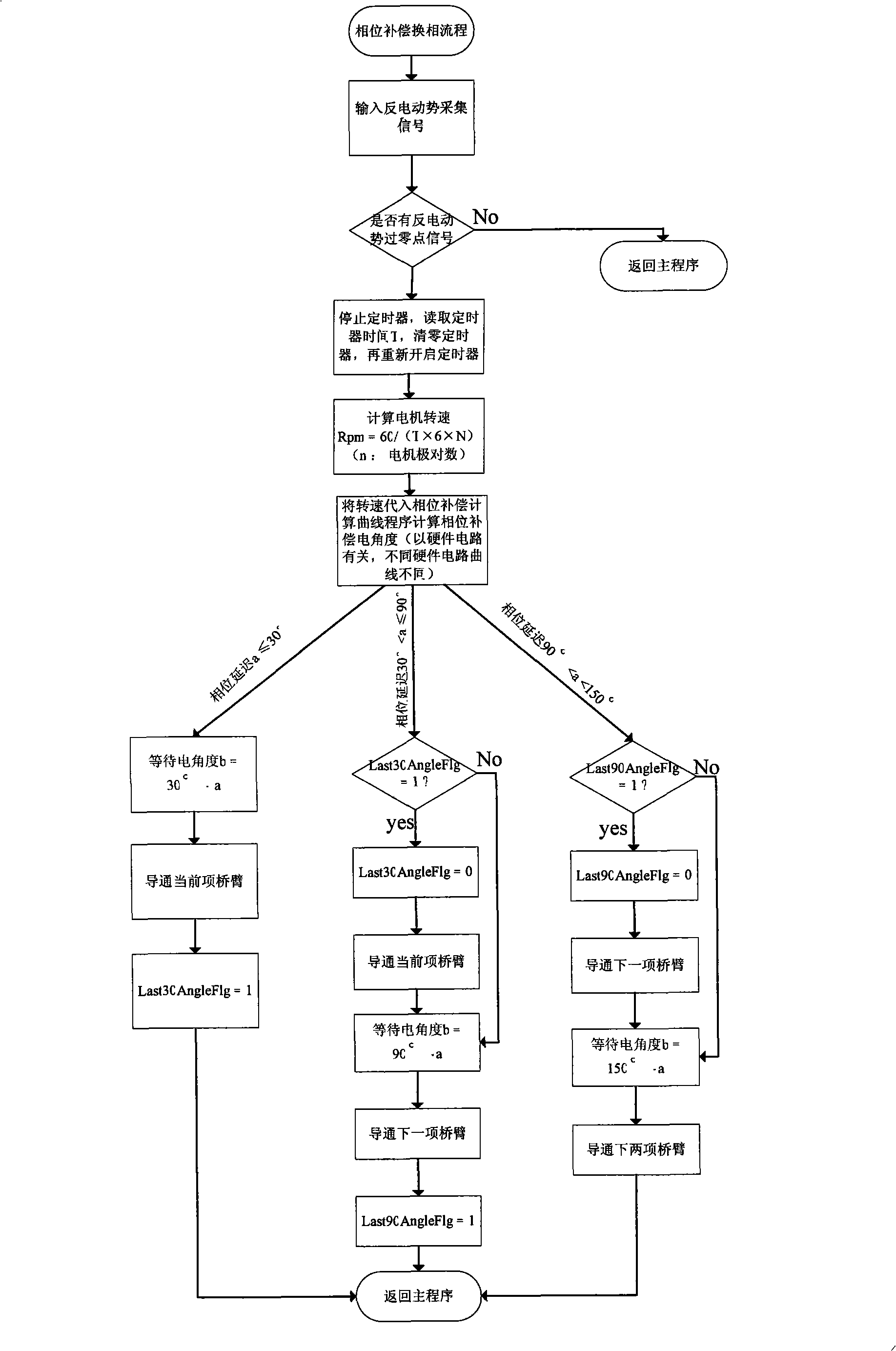

[0016] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

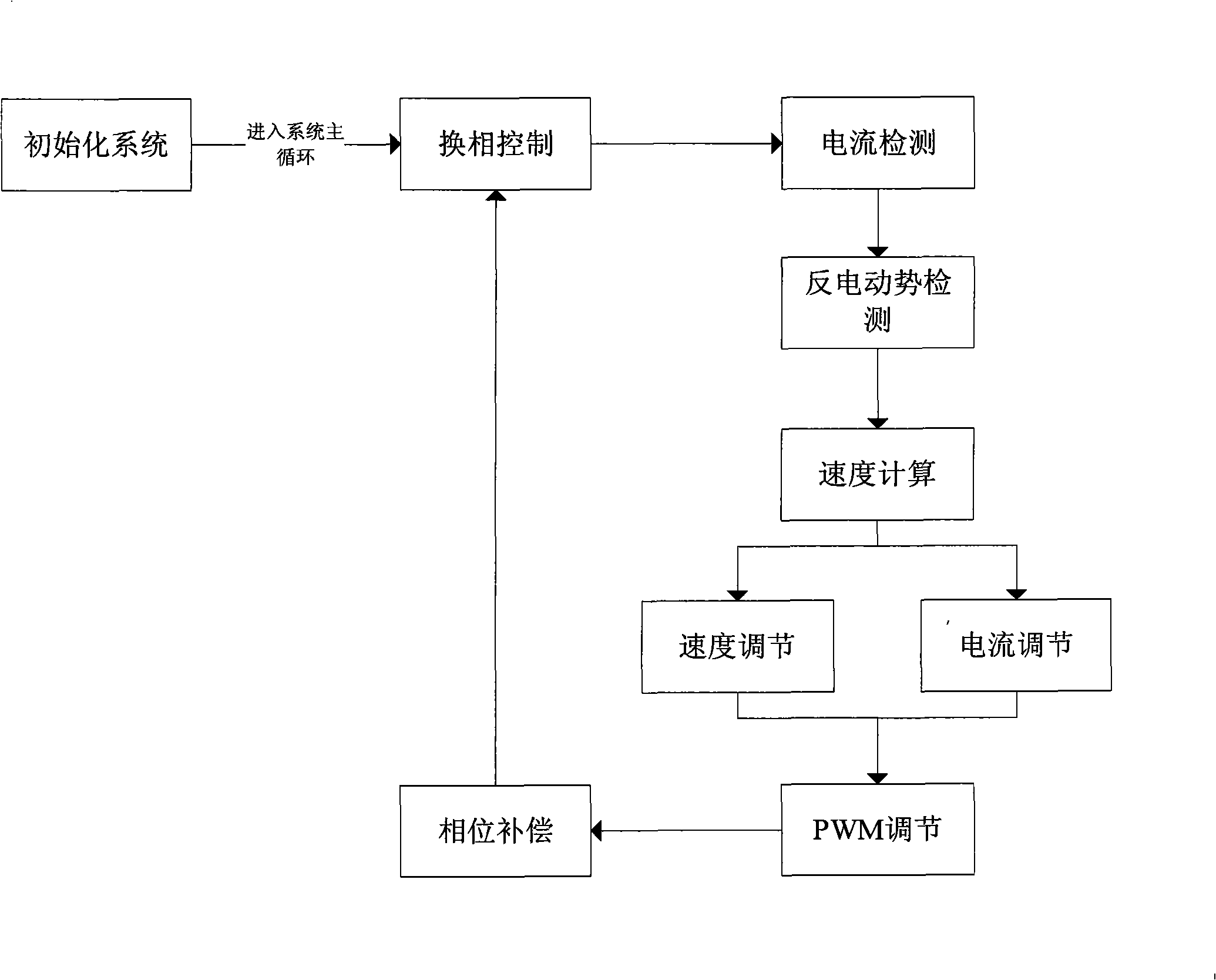

[0017] Phase correction control method for brushless DC motor without position sensor in electric vehicle air conditioning control system

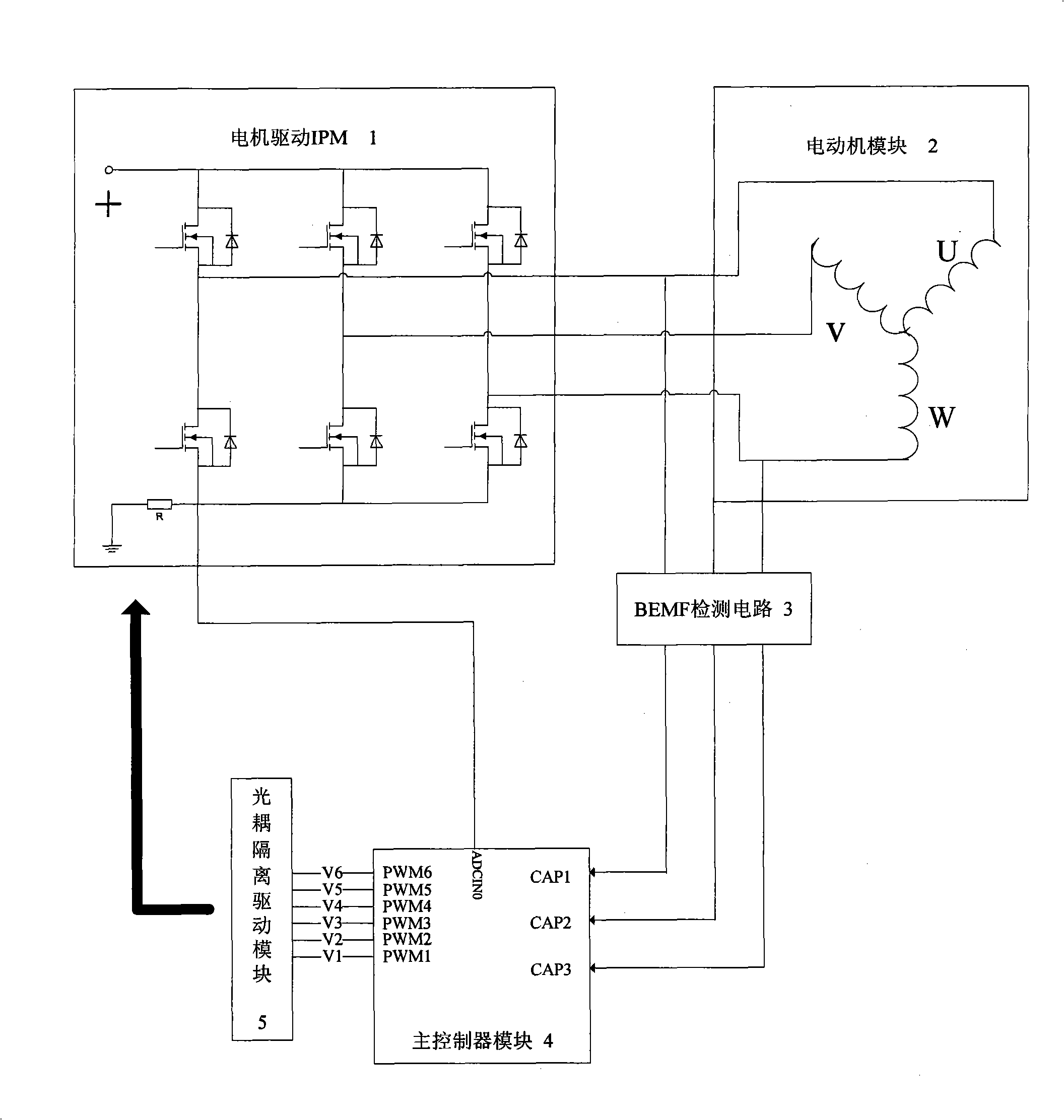

[0018] The composition of the brushless DC motor drive system adopting this specific implementation method is as follows: figure 1 shown. Including: main controller module 4, motor module 2, motor drive integrated power module (Integrated PowerModule, referred to as IPM) 1, BEMF detection circuit 3 composed of BEMF acquisition module, filter circuit and comparison circuit module, and used to isolate the main control The device module 4 and the optocoupler isolation drive module 5 of the motor drive IPM 1.

[0019] The main controller module 4 includes a single-chip microcomputer and a digital signal processor (Digital Signal Processing, referred to as DSP), and the single-chip microcomputer sends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com